Return to Section TOC

Return to Master TOC

THEORY OF OPERATION |

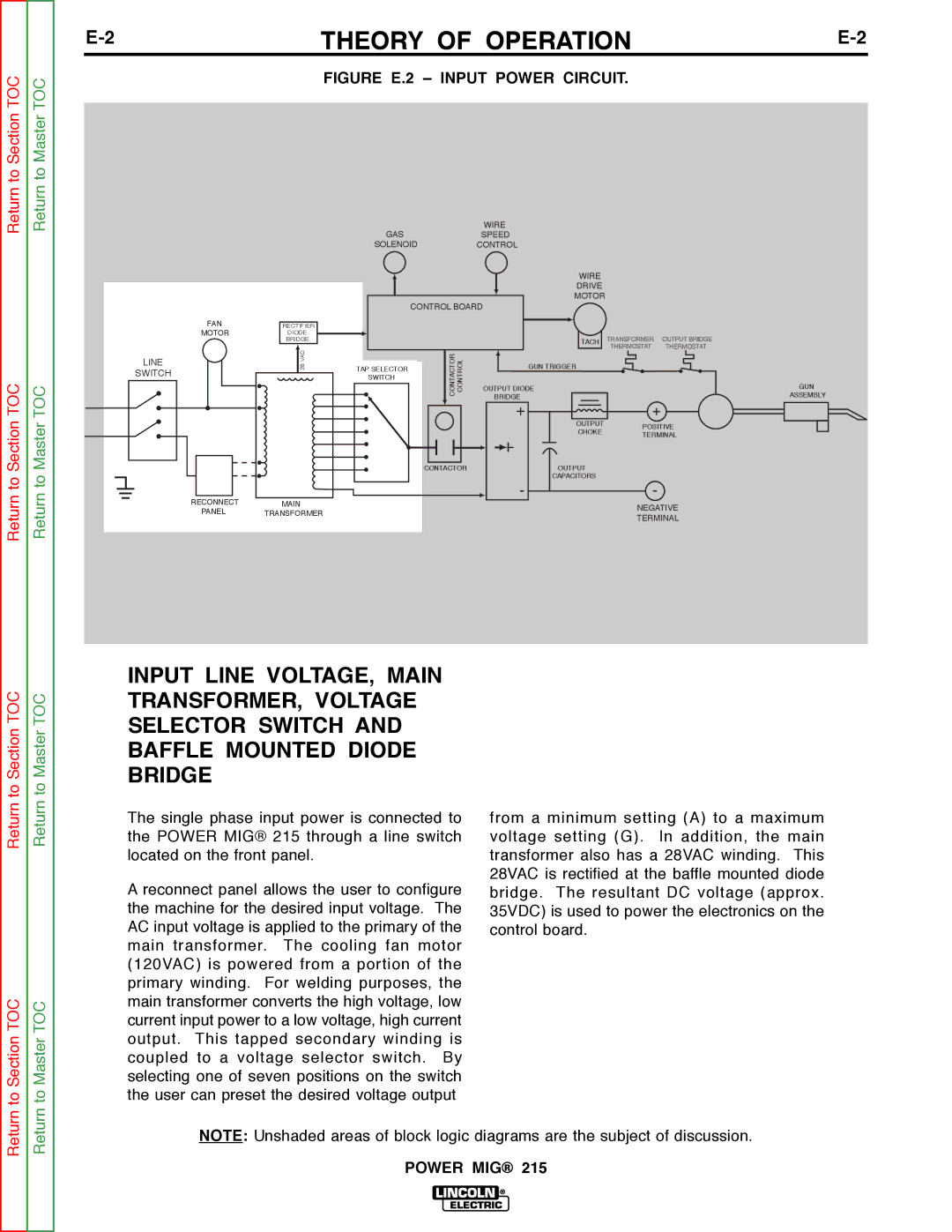

FIGURE E.2 – INPUT POWER CIRCUIT.

WIRE

GASSPEED

SOLENOIDCONTROL

FAN

MOTOR

LINE

SWITCH

RECTIFIER

DIODE

BRIDGE

VAC28TAP SELECTOR SWITCH

CONTROL BOARD

CONTACTOR | CONTROL |

CONTACTOR

WIRE

DRIVE

MOTOR

TACH

GUN TRIGGER

OUTPUT DIODE

BRIDGE

+

OUTPUT

CHOKE

OUTPUT

CAPACITORS

-

TRANSFORMER | OUTPUT BRIDGE | ||||||

THERMOSTAT | THERMOSTAT | ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

+

POSITIVE

TERMINAL

-

GUN

ASSEMBLY

INPUT LINE VOLTAGE, MAIN TRANSFORMER, VOLTAGE SELECTOR SWITCH AND BAFFLE MOUNTED DIODE BRIDGE

Return

to Section TOC

Return

to Master TOC

The single phase input power is connected to the POWER MIG® 215 through a line switch located on the front panel.

A reconnect panel allows the user to configure the machine for the desired input voltage. The AC input voltage is applied to the primary of the main transformer. The cooling fan motor (120VAC) is powered from a portion of the primary winding. For welding purposes, the main transformer converts the high voltage, low current input power to a low voltage, high current output. This tapped secondary winding is coupled to a voltage selector switch. By selecting one of seven positions on the switch the user can preset the desired voltage output

from a minimum setting (A) to a maximum voltage setting (G). In addition, the main transformer also has a 28VAC winding. This 28VAC is rectified at the baffle mounted diode bridge. The resultant DC voltage (approx. 35VDC) is used to power the electronics on the control board.