Ranger TM

Safety

California Proposition 65 Warnings

Electric Shock can kill

Cylinder may explode if damaged

Précautions DE Sûreté

Master Table of Contents for ALL Sections

Table of Contents Installation Section

Installation

Technical Specifications Ranger

Location and Ventilation

Safety Precautions

Storing

Tilting

PRE-OPERATION Engine Service

Stacking

Lifting

Muffler Relocation

Electrical Output Connections

Spark Arrester

Welding Cable Connections

Cable Length

Auxiliary Power RECEPTACLES, PLUGS, and HAND-HELD Equipment

Premises Wiring

Circuit Breakers

Figure A.2 Connection of Ranger 9 to Premises Wiring

Table of Contents Operation Section

Operating Instructions

Safety Instructions

Operation

General Description

Recommended Applications

Design Features Advantages

Operational Features and Controls

Welder

Limitations

Controls and Settings

Welding Capability

WELDER/GENERATOR Controls

Return to Section To Section TOC

Operation

Engine Operation

Gasoline Engine Controls

Stopping the Engine

Before Starting the Engine

Starting the Engine

BREAK-IN Period

Operation

Welding Operation

General Information

To Use the Ranger 9 for AC/DC TIG Constant Current Welding

Operation

Summary of Welding Processes and Machine Settings

Table B.3 Summary of Welding Processes

Auxiliary Power

Powering Motors

Table B.5 Simultaneous Welding and Auxiliary Power

Output Selector

Table B.6 Typical Generator Power Applications

Suggested Power Applications Running Watts Start-up Watts

Table of Contents Accessories

OPTIONS/ACCESSORIES

TIG Welding

Electric Shock can kill

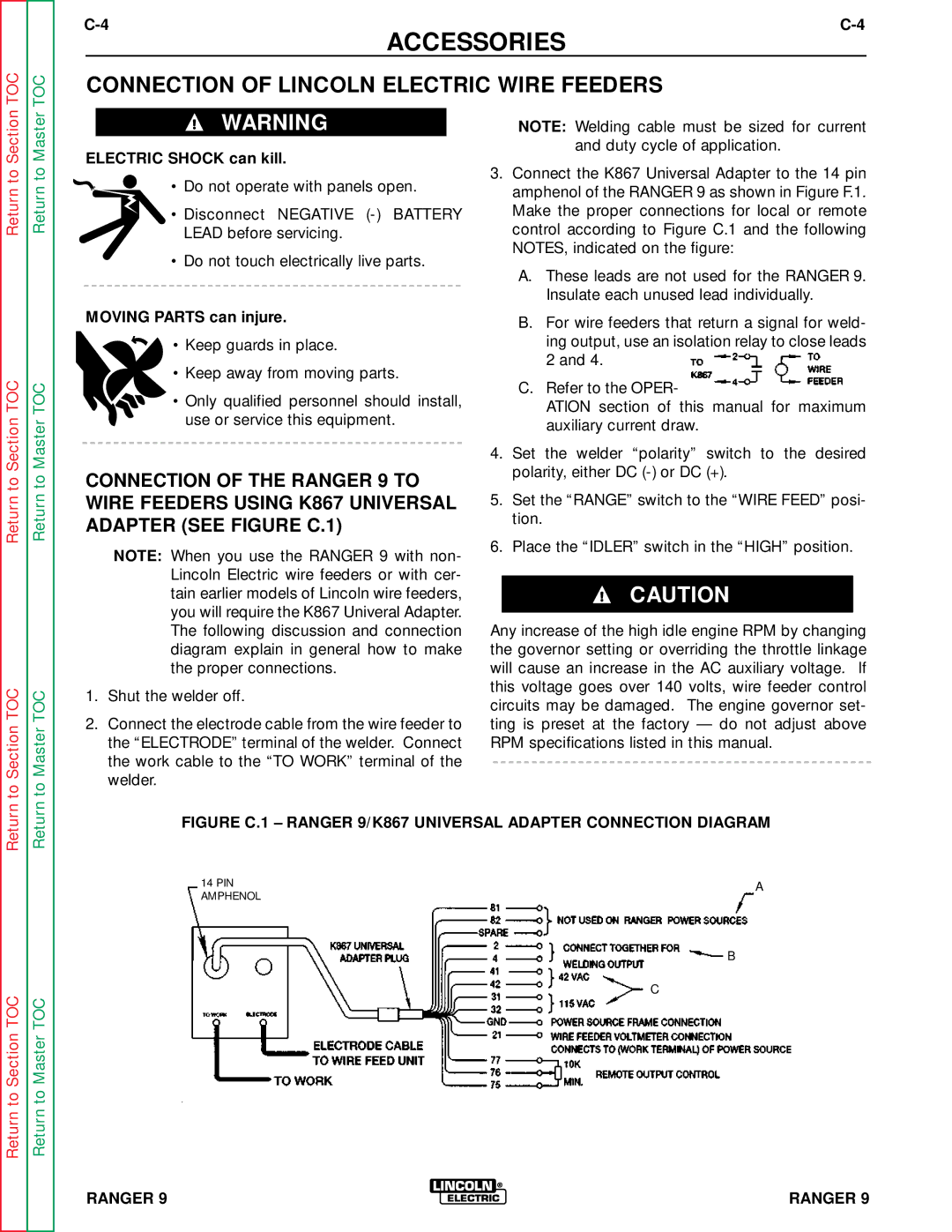

Connection of Lincoln Electric Wire Feeders

Moving Parts can injure

Figure C.2 Ranger 9/LN-25 Across the ARC Connection Diagram

Accessories

Accessories

Accessories

Figure C.6 Ranger 9/LN-8 Connection Diagram

Connection of the LN-8 to the Ranger 9 see Figure C.6

Figure C.7 Ranger 9/LN-742 Connection Diagram

Connection of the LN-742 to the Ranger 9 see Figure C.7

115V Receptacle

Table of Contents Maintenance

Routine and Periodic Maintenance

Engine Maintenance

Figure D.1 OIL Drain and Refill Location

Figure D.2 AIR Cleaner COMPONENTS, Onan Engine

Figure D.3 SET Spark Plug GAP

Every 50 Hours

Daily or Before Starting Engine

Every 25 Hours

Every 100 Hours

Battery Maintenance

WELDER/GENERATOR Maintenance

Figure D.4 Brush Removal and Replacement

Figure D.6 Major Component Locations

Table of Contents Theory of Operation Section

BATTERY, STARTER, ENGINE, ROTOR, STATOR, and Idler Solenoid

Theory of Operation

Rotor Field FEEDBACK, AUXILIARY, and Wire Feeder Power

Weld WINDING, REACTOR, Range Switch

Figure E.4 Weld WINDING, REACTOR, and Range Switch

Output BRIDGE, CHOKE, Polarity SWITCH, and Output Terminals

Table of Contents Troubleshooting & Repair Section

Troubleshooting & Repair

HOW to USE Troubleshooting Guide

PC Board Troubleshooting Procedures

PC Board can be damaged by static electricity

Troubleshooting Guide

Output Problems

Perform the Output Rectifier

Field Winding Voltage Test

Adjustment Test

Troubleshooting Guide

Troubleshooting & Repair

Engine Problems

Welding Terminals

Charging Circuit Test

Welding Problems

Function Problems

Perform the Auxiliary and Field

Troubleshooting & Repair

Remotely Controlled

Tor drops out, then make sure

Test Description

Rotor Voltage Test

Materials Needed

Test Procedure

Rotor Resistance Test

Rotor Resistance Test

Troubleshooting & Repair

Auxiliary and Field Winding Test

Auxiliary and Field Winding Test

To test the field winding

To test the feeder winding

Figure F.4A 14 PIN Amphenol PIN Assignments

Troubleshooting & Repair

Output Rectifier Bridge Test

Output Rectifier Bridge Test

Charging Circuit Test

Charging Circuit Test

Engine Throttle Adjustment Test

Engine Throttle Adjustment Test

Strobe-tach Method

High Idle Adjustment NUT LOW Idle Adjustment NUT

Frequency Counter Method

Oscilloscope Method Vibratach Method

Normal Open Circuit Voltage Waveform 115VAC Supply

Scope Settings

High Idle no Load Output Control AT Maximum

Machine Loaded

Typical DC Weld Output Voltage Waveform CV Mode High TAP

Machine Loaded to 250 Amps AT 25VDC

Typical DC Weld Output Voltage Waveform

Machine Loaded to 250 Amps AT 25 VDC

Typical AC Weld Output Voltage Waveform

Abnormal Open Circuit DC Weld Voltage Waveform

Abnormal Open Circuit Weld Voltage Waveform High CV Mode

Normal Open Circuit Weld Voltage Waveform High CV Mode

Normal Open Circuit DC Weld Voltage Waveform

Normal Open Circuit AC Weld Voltage Waveform

Brush Removal and Replacement

Description

Brush Removal and Replacement

Procedure

Slip Rings

Figure F.10 Brush LEADS/BRUSHES Retained with Cable TIE

Field Capacitor AND/OR Rectifier Bridge Removal Replacement

Replacement

Field Capacitor AND/OR Rectifier Bridge Removal

Procedure Rectifier Bridge Removal and Replacement

Printed Circuit Board Removal Replacement

Printed Circuit Board Removal and Replacement

Figure F.12 Printed Circuit Board Location

Printed Circuit Board Removal

Output Rectifier Bridge Removal Replacement

Remove the case top, then reinstall the fuel cap

Output Rectifier Bridge Removal

To Section TOC

Output Capacitor Removal Replacement

Output Capacitor Removal

Section TOC

Output Contactor Removal Replacement

Output Contactor Removal

Figure F.15 Output Contactor Location

Troubleshooting & REPAIRs

ENGINE/ROTOR Removal and Replacement

Instructions

ENGINE/ROTOR Removal

Figure F.17 Component LOCATIONS, ENGINE/ROTOR Removal

Engine and Rotor Removal Procedure

Rotor Removal Procedure

Figure F.18 Engine and Rotor Removed from Stator

Replacement KIT S20788

Reassembly Procedure

Retest After Repair

Table of Contents Diagrams Section

Diagrams

Wiring Diagram Ranger 9 Onan Code

Wiring Diagram Ranger 9 Onan CSA Code

Ranger 9 Onan CSA Version

Control PC Board L9062 Schematic

Snubber

RF Bypass PC Board M16675 Schematic

CLEVELAND, Ohio U

Dimension Print

Control PC Board L9062 Layout

Control PC Board L9062 Components

TP1 MOV-50VRMS,15J,14MM

Bypass

RF-BYPASS PC Board M16675 Layout

RF-BYPASS PC Board M16675 Components

Description