. A complete Parts List is available at www.MillerWelds.com

4-4. Dimensions For Units With Optional Running Gear

| Dimensions |

|

|

| All Running Gear Options: |

|

|

Height |

|

| |

(To Top Of Handle |

|

| |

|

|

| |

| Assembly) |

|

|

|

|

| C |

A | Protective Cage Width: |

| D |

| 26 in (660 mm) |

|

|

B | Running Gear Width: |

|

|

32 in (813 mm) |

|

| |

|

|

| |

C | Protective Cage Length: |

|

|

48 in (1219 mm) |

|

| |

| A | B | |

|

| ||

|

|

| |

| Running Gear Length: | B |

|

D |

|

| |

45−1/2 in (1156 mm) |

|

| |

|

|

|

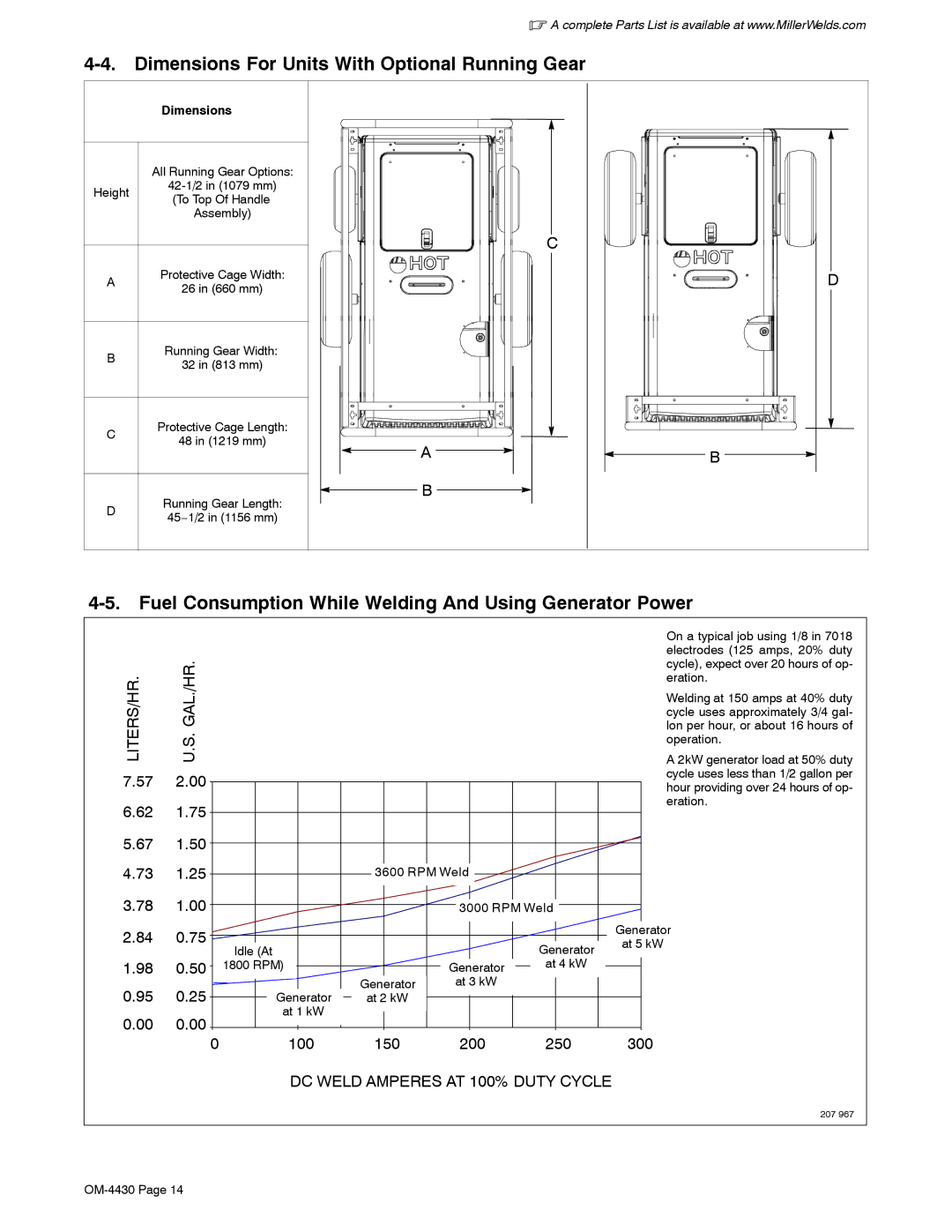

4-5. Fuel Consumption While Welding And Using Generator Power

LITERS/HR. | U.S. GAL./HR. |

7.572.00

6.621.75

5.671.50

4.731.25

3.781.00

2.840.75

1.980.50

0.950.25

0.00 0.00

|

|

|

|

| 3600 RPM Weld |

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 3000 RPM Weld | |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Idle (At |

|

|

|

|

|

|

|

|

| Generator | |||

1800 RPM) |

|

|

|

|

|

| Generator |

|

| at 4 kW | |||

|

|

|

|

|

|

| |||||||

|

|

|

|

| Generator |

| at 3 kW |

|

|

|

| ||

| Generator |

| at 2 kW |

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

| |||||

| at 1 kW |

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

On a typical job using 1/8 in 7018 electrodes (125 amps, 20% duty cycle), expect over 20 hours of op- eration.

Welding at 150 amps at 40% duty cycle uses approximately 3/4 gal- lon per hour, or about 16 hours of operation.

A 2kW generator load at 50% duty cycle uses less than 1/2 gallon per hour providing over 24 hours of op- eration.

Generator at 5 kW

0 | 100 | 150 | 200 | 250 | 300 |

DC WELD AMPERES AT 100% DUTY CYCLE

207 967