. A complete Parts List is available at www.MillerWelds.com

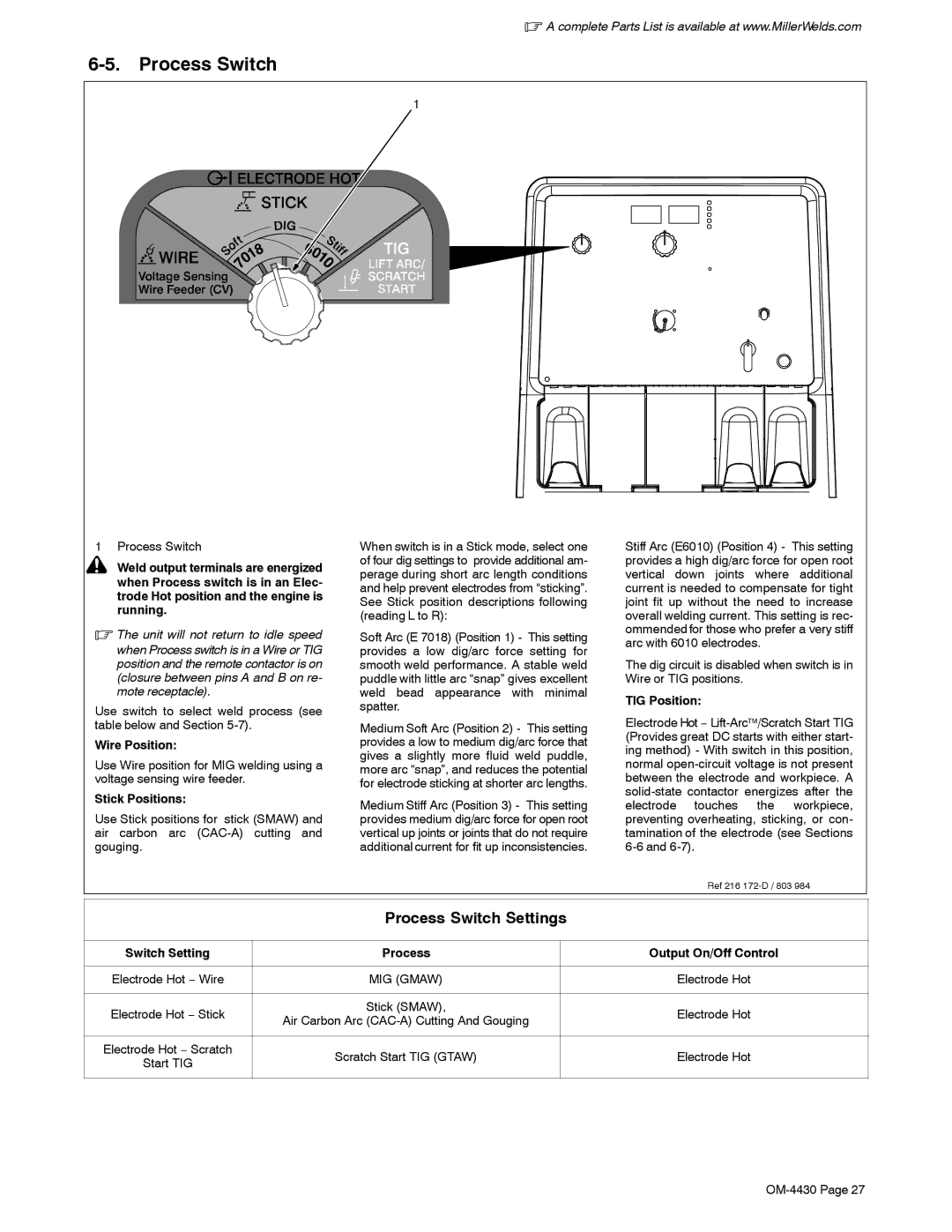

6-5. Process Switch

1

1 Process Switch

! Weld output terminals are energized when Process switch is in an Elec- trode Hot position and the engine is running.

.The unit will not return to idle speed

when Process switch is in a Wire or TIG position and the remote contactor is on (closure between pins A and B on re- mote receptacle).

Use switch to select weld process (see table below and Section

Wire Position:

Use Wire position for MIG welding using a voltage sensing wire feeder.

Stick Positions:

Use Stick positions for stick (SMAW) and air carbon arc

When switch is in a Stick mode, select one of four dig settings to provide additional am- perage during short arc length conditions and help prevent electrodes from “sticking”. See Stick position descriptions following (reading L to R):

Soft Arc (E 7018) (Position 1) - This setting provides a low dig/arc force setting for smooth weld performance. A stable weld puddle with little arc “snap” gives excellent weld bead appearance with minimal spatter.

Medium Soft Arc (Position 2) - This setting provides a low to medium dig/arc force that gives a slightly more fluid weld puddle, more arc “snap”, and reduces the potential for electrode sticking at shorter arc lengths.

Medium Stiff Arc (Position 3) - This setting provides medium dig/arc force for open root vertical up joints or joints that do not require additional current for fit up inconsistencies.

Stiff Arc (E6010) (Position 4) - This setting provides a high dig/arc force for open root vertical down joints where additional current is needed to compensate for tight joint fit up without the need to increase overall welding current. This setting is rec- ommended for those who prefer a very stiff arc with 6010 electrodes.

The dig circuit is disabled when switch is in Wire or TIG positions.

TIG Position:

Electrode Hot −

|

|

| Ref 216 |

|

|

|

|

|

|

|

|

| Process Switch Settings |

| |

|

|

|

|

Switch Setting | Process |

| Output On/Off Control |

|

|

|

|

Electrode Hot − Wire | MIG (GMAW) |

| Electrode Hot |

|

|

|

|

Electrode Hot − Stick | Stick (SMAW), |

| Electrode Hot |

Air Carbon Arc |

| ||

|

|

| |

|

|

|

|

Electrode Hot − Scratch | Scratch Start TIG (GTAW) |

| Electrode Hot |

Start TIG |

| ||

|

|

| |

|

|

|

|