. A complete Parts List is available at www.MillerWelds.com

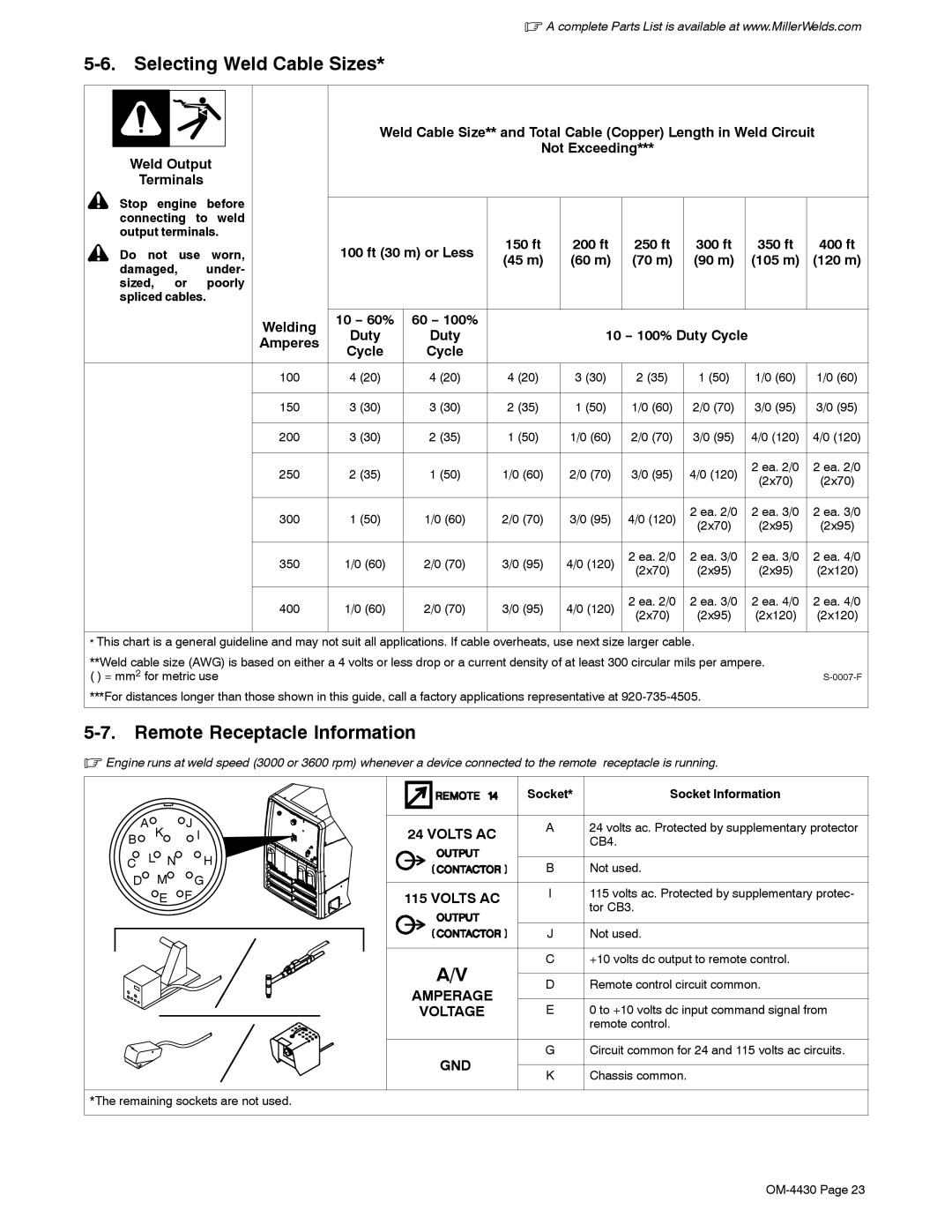

5-6. Selecting Weld Cable Sizes*

|

|

|

|

|

| Weld Cable Size** and Total Cable (Copper) Length in Weld Circuit | ||||||||

|

|

|

|

|

| |||||||||

|

|

|

|

|

|

|

| Not Exceeding*** |

|

|

|

| ||

| Weld Output |

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

| ||||

| Terminals |

|

|

|

|

|

|

|

|

|

|

| ||

! | Stop | engine | before |

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

| |||||

| connecting to weld |

|

|

|

|

|

|

|

|

|

| |||

| output terminals. |

|

|

| 150 ft | 200 ft | 250 ft | 300 ft |

| 350 ft | 400 ft | |||

! | Do not use | worn, |

| 100 ft (30 m) or Less |

| |||||||||

| (45 m) | (60 m) | (70 m) | (90 m) |

| (105 m) | (120 m) | |||||||

| damaged, | under- |

|

|

|

| ||||||||

|

|

|

|

|

|

|

|

|

|

| ||||

| sized, |

| or | poorly |

|

|

|

|

|

|

|

|

|

|

| spliced cables. |

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Welding | 10 − 60% | 60 − 100% |

|

|

|

|

|

|

|

|

|

|

|

| Duty | Duty |

| 10 − 100% Duty Cycle |

|

| ||||

|

|

|

|

| Amperes |

|

|

| ||||||

|

|

|

|

| Cycle | Cycle |

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 100 | 4 (20) | 4 (20) | 4 (20) | 3 (30) | 2 (35) | 1 (50) |

| 1/0 (60) | 1/0 (60) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 150 | 3 (30) | 3 (30) | 2 (35) | 1 (50) | 1/0 (60) | 2/0 (70) |

| 3/0 (95) | 3/0 (95) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 200 | 3 (30) | 2 (35) | 1 (50) | 1/0 (60) | 2/0 (70) | 3/0 (95) |

| 4/0 (120) | 4/0 (120) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 250 | 2 (35) | 1 (50) | 1/0 (60) | 2/0 (70) | 3/0 (95) | 4/0 (120) |

| 2 ea. 2/0 | 2 ea. 2/0 |

|

|

|

|

|

| (2x70) | (2x70) | |||||||

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 300 | 1 (50) | 1/0 (60) | 2/0 (70) | 3/0 (95) | 4/0 (120) | 2 ea. 2/0 |

| 2 ea. 3/0 | 2 ea. 3/0 |

|

|

|

|

| (2x70) |

| (2x95) | (2x95) | ||||||

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 350 | 1/0 (60) | 2/0 (70) | 3/0 (95) | 4/0 (120) | 2 ea. 2/0 | 2 ea. 3/0 |

| 2 ea. 3/0 | 2 ea. 4/0 |

|

|

|

|

| (2x70) | (2x95) |

| (2x95) | (2x120) | |||||

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 400 | 1/0 (60) | 2/0 (70) | 3/0 (95) | 4/0 (120) | 2 ea. 2/0 | 2 ea. 3/0 |

| 2 ea. 4/0 | 2 ea. 4/0 |

|

|

|

|

| (2x70) | (2x95) |

| (2x120) | (2x120) | |||||

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

*This chart is a general guideline and may not suit all applications. If cable overheats, use next size larger cable.

**Weld cable size (AWG) is based on either a 4 volts or less drop or a current density of at least 300 circular mils per ampere.

( ) = mm2 for metric useS-0007-F

***For distances longer than those shown in this guide, call a factory applications representative at

5-7. Remote Receptacle Information

.Engine runs at weld speed (3000 or 3600 rpm) whenever a device connected to the remote receptacle is running.

|

|

|

|

| Socket* | Socket Information |

A | K | J | 24 VOLTS AC | A | 24 volts ac. Protected by supplementary protector | |

B |

| I | ||||

|

| CB4. | ||||

|

|

|

|

| ||

C | L N | H |

| B | Not used. | |

D |

| M | G |

| ||

|

| I | 115 volts ac. Protected by supplementary protec- | |||

|

| E | F | 115 VOLTS AC | ||

|

|

|

|

|

| tor CB3. |

|

|

|

|

| J | Not used. |

|

|

|

| A/V | C | +10 volts dc output to remote control. |

|

|

|

| D | Remote control circuit common. | |

|

|

|

| AMPERAGE | ||

|

|

|

| E | 0 to +10 volts dc input command signal from | |

|

|

|

| VOLTAGE | ||

|

|

|

|

|

| remote control. |

|

|

|

| GND | G | Circuit common for 24 and 115 volts ac circuits. |

|

|

|

| K | Chassis common. | |

|

|

|

|

| ||

*The remaining sockets are not used.