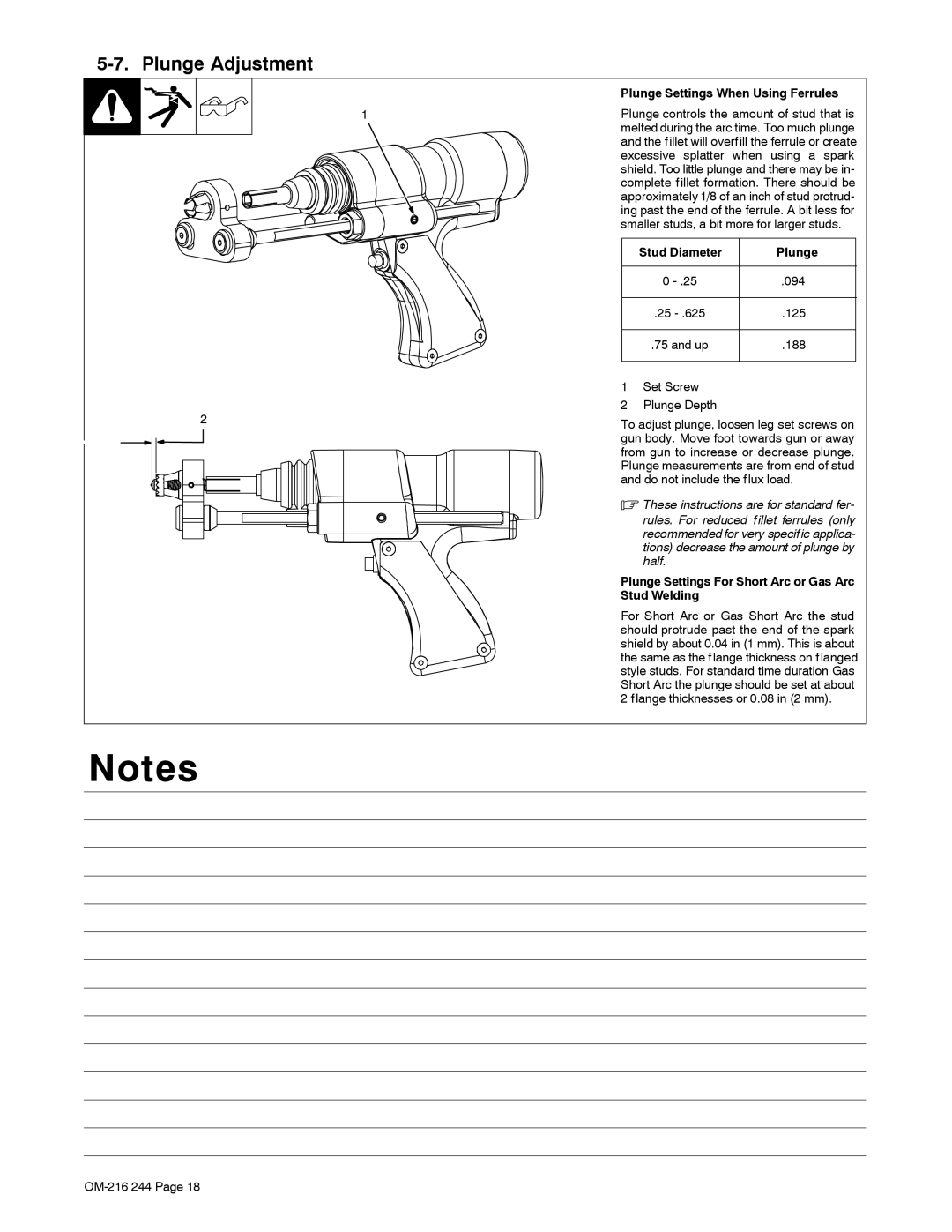

5-7. Plunge Adjustment

| Plunge Settings When Using Ferrules | ||

1 | Plunge controls the amount of stud that is | ||

| melted during the arc time. Too much plunge | ||

| and the fillet will overfill the ferrule or create | ||

| excessive splatter when using a spark | ||

| shield. Too little plunge and there may be in- | ||

| complete fillet formation. There should be | ||

| approximately 1/8 of an inch of stud protrud- | ||

| ing past the end of the ferrule. A bit less for | ||

| smaller studs, a bit more for larger studs. | ||

|

| Stud Diameter | Plunge |

|

| 0 | .094 |

|

| .25 | .125 |

|

| .75 and up | .188 |

| 1 | Set Screw |

|

| 2 | Plunge Depth |

|

2 | To adjust plunge, loosen leg set screws on |

| |

| gun body. Move foot towards gun or away |

| from gun to increase or decrease plunge. |

| Plunge measurements are from end of stud |

| and do not include the flux load. |

| . These instructions are for standard fer- |

| rules. For reduced fillet ferrules (only |

| recommended for very specific applica- |

| tions) decrease the amount of plunge by |

| half. |

| Plunge Settings For Short Arc or Gas Arc |

| Stud Welding |

| For Short Arc or Gas Short Arc the stud |

| should protrude past the end of the spark |

| shield by about 0.04 in (1 mm). This is about |

| the same as the flange thickness on flanged |

| style studs. For standard time duration Gas |

| Short Arc the plunge should be set at about |

| 2 flange thicknesses or 0.08 in (2 mm). |

Notes