SECTION 7 − OPERATION - STUD GUN

7-1. Stud Gun Tool Functions

Y Disconnect gun from power source before installing or removing compo- nents.

The stud gun automates the stud welding process.

Several key functions are:

• Holds the ferrule, spark shield or gas de- livery system

• Holds the stud

• Strikes the arc

• Establishes the arc length (lift distance)

• Thru the power source, the gun controls the arc time

• Controls rate of plunge of the stud into the base metal

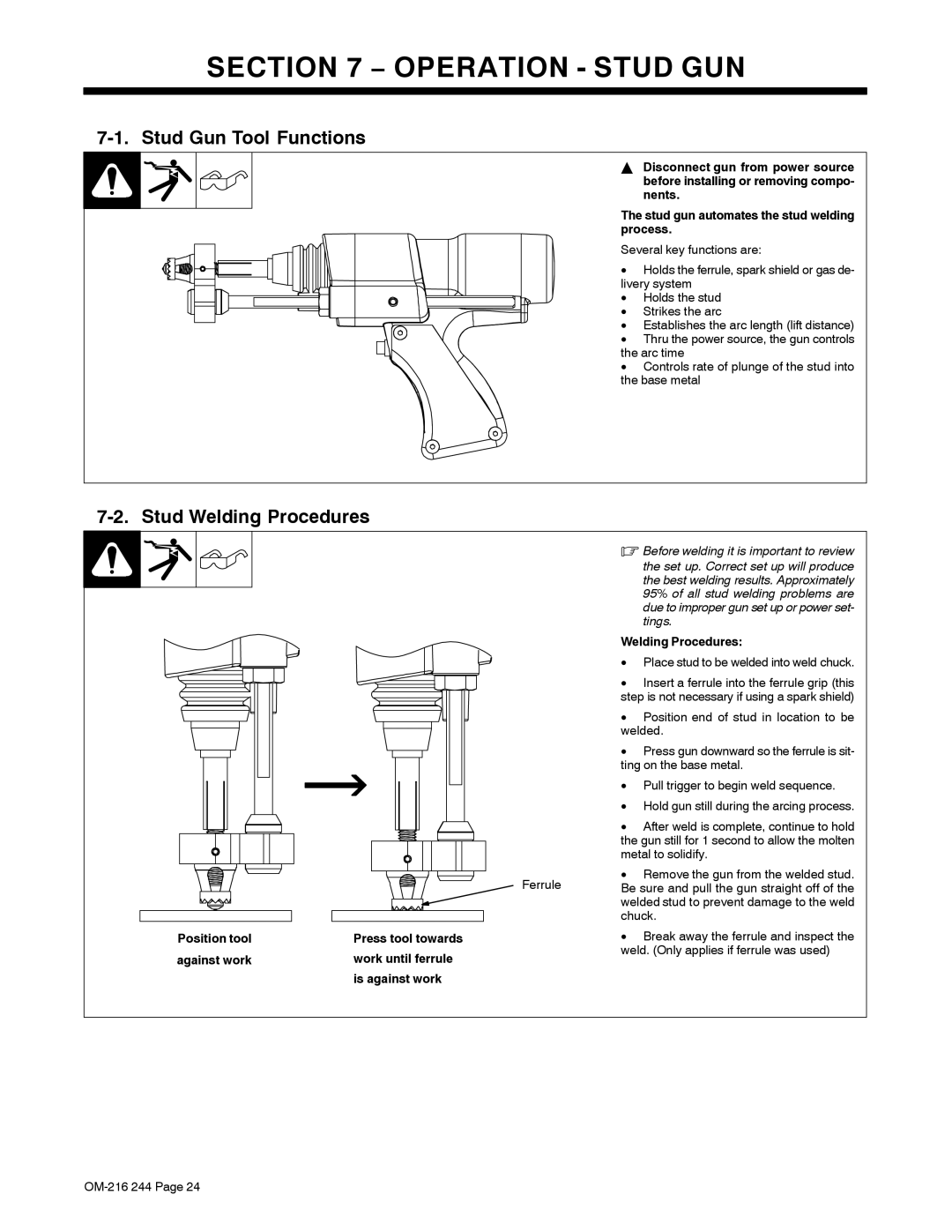

7-2. Stud Welding Procedures

. Before welding it is important to review the set up. Correct set up will produce the best welding results. Approximately 95% of all stud welding problems are due to improper gun set up or power set-

|

| tings. |

|

| Welding Procedures: |

|

| • Place stud to be welded into weld chuck. |

|

| • Insert a ferrule into the ferrule grip (this |

|

| step is not necessary if using a spark shield) |

|

| • Position end of stud in location to be |

|

| welded. |

|

| • Press gun downward so the ferrule is sit- |

|

| ting on the base metal. |

|

| • Pull trigger to begin weld sequence. |

|

| • Hold gun still during the arcing process. |

|

| • After weld is complete, continue to hold |

|

| the gun still for 1 second to allow the molten |

|

| metal to solidify. |

| Ferrule | • Remove the gun from the welded stud. |

| Be sure and pull the gun straight off of the | |

|

| welded stud to prevent damage to the weld |

|

| chuck. |

Position tool | Press tool towards | • Break away the ferrule and inspect the |

against work | work until ferrule | weld. (Only applies if ferrule was used) |

| ||

| is against work |

|