5-8. Adjusting Stud Lift

LIft Adjustment Table

1/16 in (1.6 mm) lift for studs up to 5/16 (7.9 mm) diameter

3/32 in (2.4 mm) lift for studs over 5/16 (7.9 mm) to 1/2 in (13 mm) diameter

1/8 in (3.2 mm) lift for studs over 1/2 (13 mm) diameter

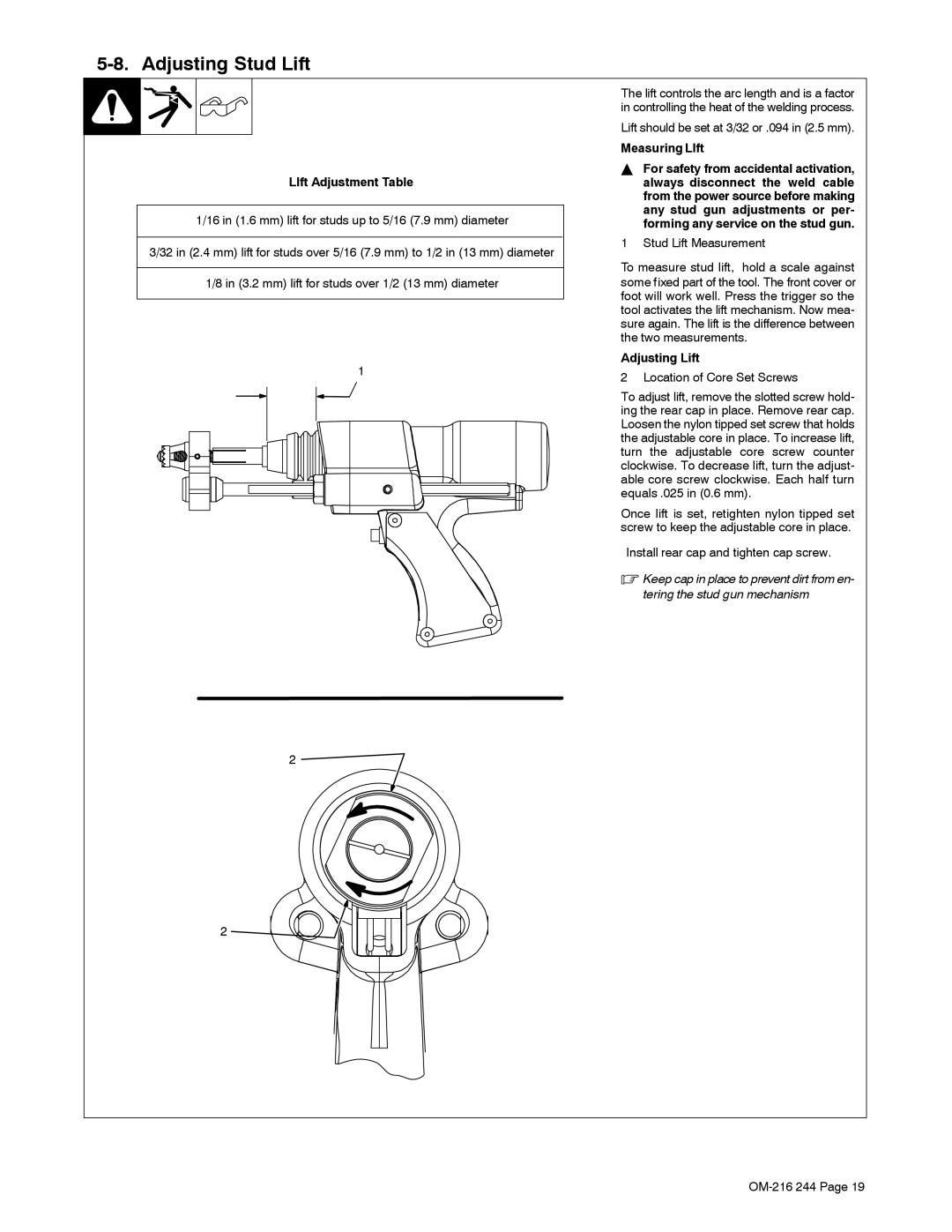

1

2

2

The lift controls the arc length and is a factor in controlling the heat of the welding process.

Lift should be set at 3/32 or .094 in (2.5 mm).

Measuring LIft

YFor safety from accidental activation, always disconnect the weld cable from the power source before making any stud gun adjustments or per- forming any service on the stud gun.

1 Stud Lift Measurement

To measure stud lift, hold a scale against some fixed part of the tool. The front cover or foot will work well. Press the trigger so the tool activates the lift mechanism. Now mea- sure again. The lift is the difference between the two measurements.

Adjusting Lift

2 Location of Core Set Screws

To adjust lift, remove the slotted screw hold- ing the rear cap in place. Remove rear cap. Loosen the nylon tipped set screw that holds the adjustable core in place. To increase lift, turn the adjustable core screw counter clockwise. To decrease lift, turn the adjust- able core screw clockwise. Each half turn equals .025 in (0.6 mm).

Once lift is set, retighten nylon tipped set screw to keep the adjustable core in place.

Install rear cap and tighten cap screw.

.Keep cap in place to prevent dirt from en- tering the stud gun mechanism