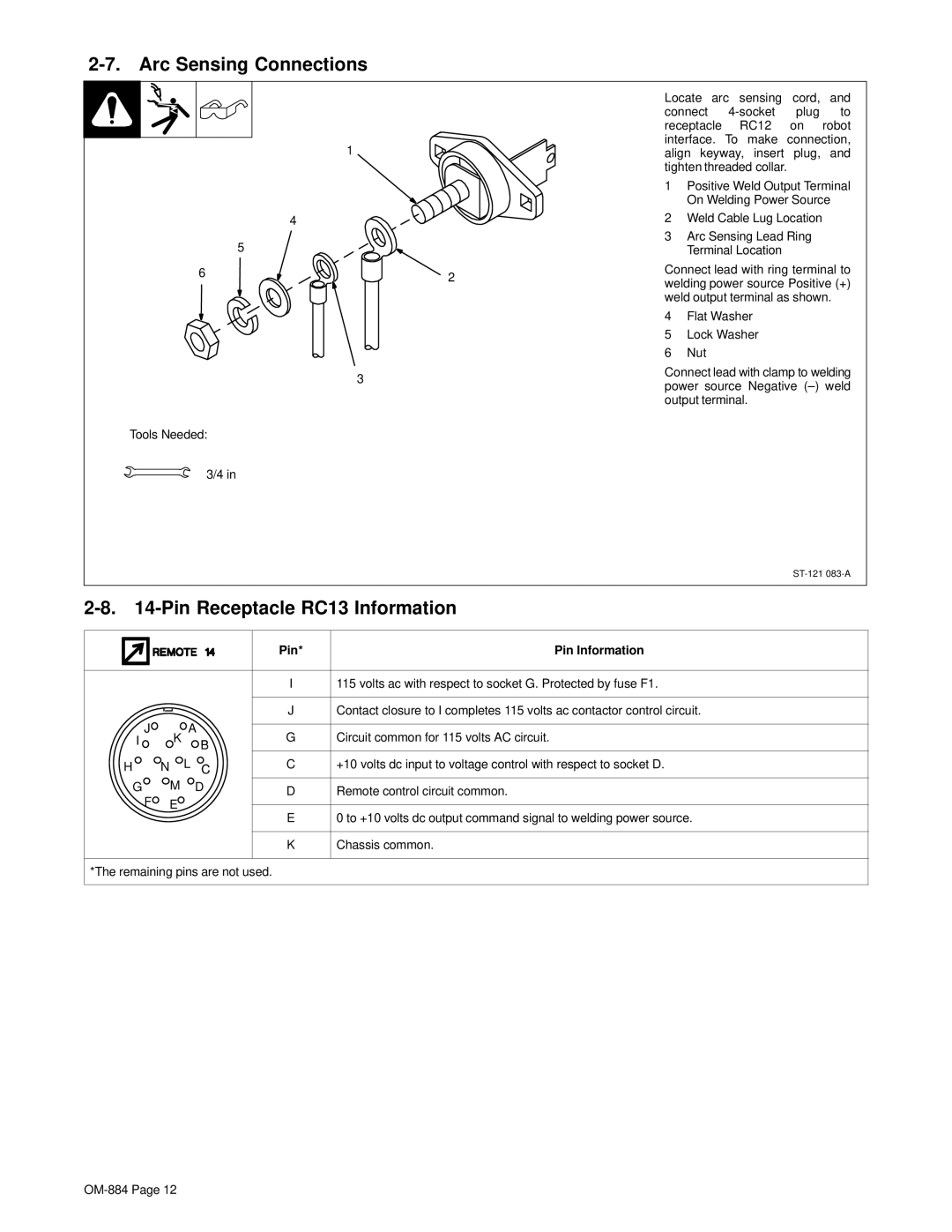

2-7. Arc Sensing Connections

Locate arc sensing cord, and connect

1align keyway, insert plug, and tighten threaded collar.

|

| 1 | Positive Weld Output Terminal |

|

|

| On Welding Power Source |

4 |

| 2 | Weld Cable Lug Location |

5 |

| 3 | Arc Sensing Lead Ring |

|

| Terminal Location | |

6 | 2 | Connect lead with ring terminal to | |

| welding power source Positive (+) | ||

|

| ||

|

| weld output terminal as shown. | |

|

| 4 | Flat Washer |

|

| 5 | Lock Washer |

|

| 6 | Nut |

3

Tools Needed:

3/4 in

Connect lead with clamp to welding power source Negative

2-8. 14-Pin Receptacle RC13 Information

|

|

| Pin* | Pin Information |

|

|

| I | 115 volts ac with respect to socket G. Protected by fuse F1. |

|

|

| J | Contact closure to I completes 115 volts ac contactor control circuit. |

J | K | A | G | Circuit common for 115 volts AC circuit. |

I | B | |||

|

|

|

| |

H | N | L C | C | +10 volts dc input to voltage control with respect to socket D. |

G | M | D | D | Remote control circuit common. |

F | E |

| ||

| E | 0 to +10 volts dc output command signal to welding power source. | ||

|

|

| ||

|

|

| K | Chassis common. |

*The remaining pins are not used.