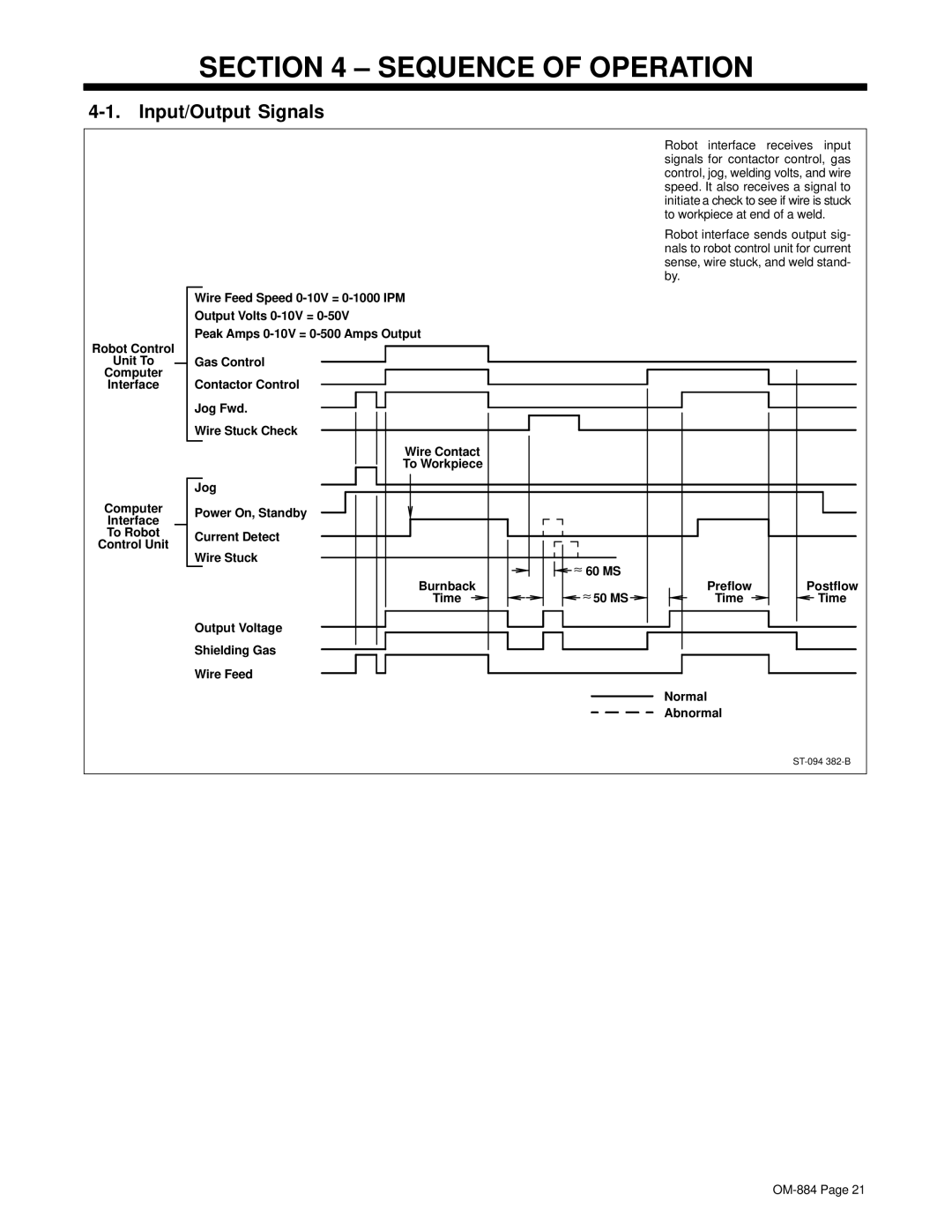

SECTION 4 – SEQUENCE OF OPERATION

4-1. Input/Output Signals

Robot Control

Unit To

Computer

Interface

Computer

Interface

To Robot

Control Unit

Robot interface receives input signals for contactor control, gas control, jog, welding volts, and wire speed. It also receives a signal to initiate a check to see if wire is stuck to workpiece at end of a weld.

Robot interface sends output sig- nals to robot control unit for current sense, wire stuck, and weld stand- by.

Wire Feed Speed

Output Volts

Peak Amps

Gas Control

Contactor Control

Jog Fwd.

Wire Stuck Check

Wire Contact

To Workpiece

Jog

Power On, Standby

Current Detect

Wire Stuck

≈ 60 MS

Burnback | ≈ 50 MS | Preflow | Postflow |

Time | Time | Time |