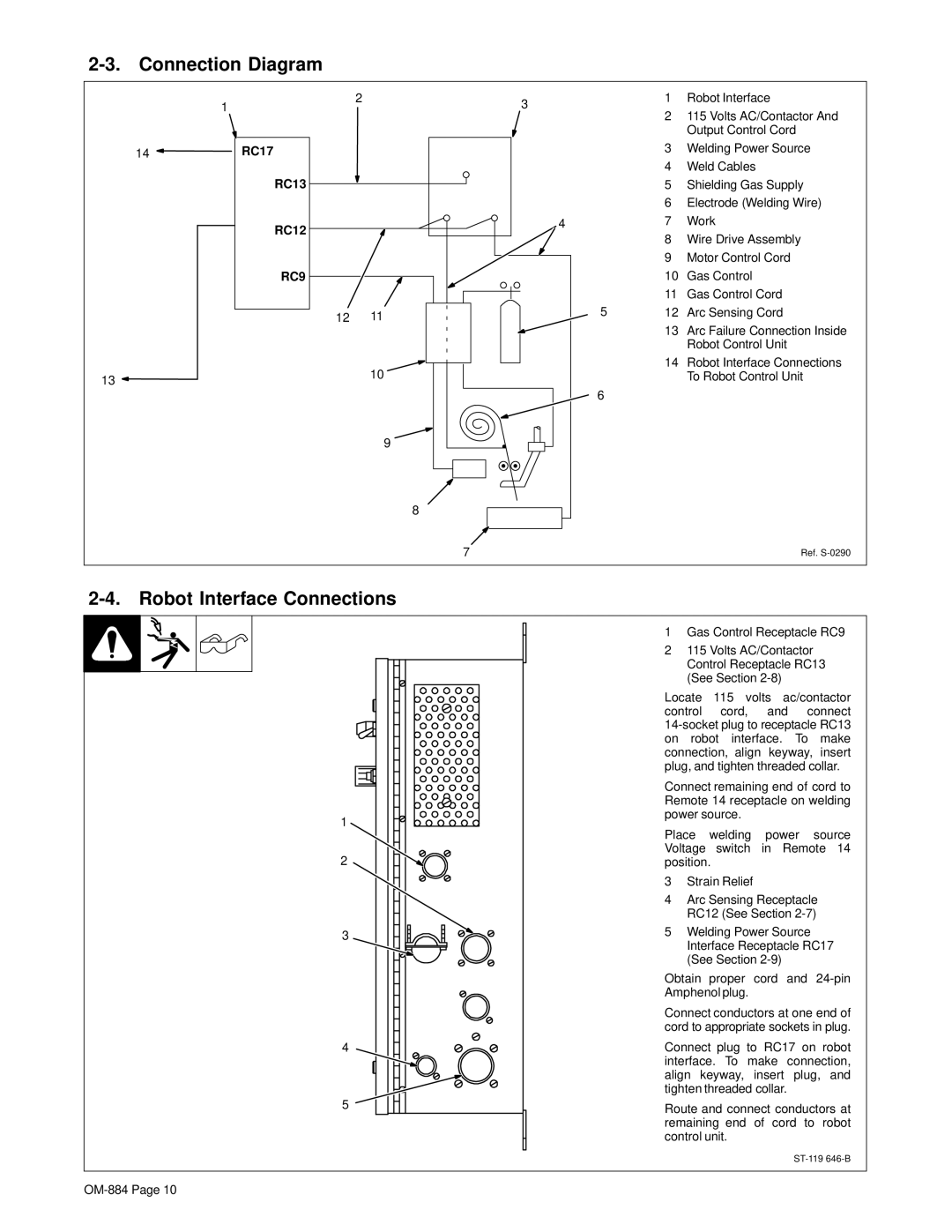

2-3. Connection Diagram

14 ![]()

13 ![]()

1 | 2 |

| 3 | 1 | Robot Interface |

|

| 2 | 115 Volts AC/Contactor And | ||

|

|

|

| ||

|

|

|

|

| Output Control Cord |

RC17 |

|

|

| 3 | Welding Power Source |

|

|

|

| 4 | Weld Cables |

RC13 |

|

|

| 5 | Shielding Gas Supply |

|

|

|

| 6 | Electrode (Welding Wire) |

RC12 |

|

| 4 | 7 | Work |

|

|

| 8 | Wire Drive Assembly | |

|

|

|

| ||

|

|

|

| 9 | Motor Control Cord |

RC9 |

|

|

| 10 | Gas Control |

|

|

|

| 11 | Gas Control Cord |

12 |

| 11 | 5 | 12 | Arc Sensing Cord |

|

| 13 | Arc Failure Connection Inside | ||

|

|

|

| ||

|

|

|

|

| Robot Control Unit |

|

| 10 |

| 14 | Robot Interface Connections |

|

|

|

| To Robot Control Unit | |

|

|

| 6 |

|

|

|

|

| 9 |

|

|

8

7 | Ref. |

2-4. Robot Interface Connections

1

2

3

1Gas Control Receptacle RC9

2115 Volts AC/Contactor Control Receptacle RC13 (See Section

Locate 115 volts ac/contactor control cord, and connect

Connect remaining end of cord to Remote 14 receptacle on welding power source.

Place welding power source Voltage switch in Remote 14 position.

3Strain Relief

4Arc Sensing Receptacle RC12 (See Section

5Welding Power Source Interface Receptacle RC17 (See Section

4

5

Obtain proper cord and

Connect conductors at one end of cord to appropriate sockets in plug.

Connect plug to RC17 on robot interface. To make connection, align keyway, insert plug, and tighten threaded collar.

Route and connect conductors at remaining end of cord to robot control unit.