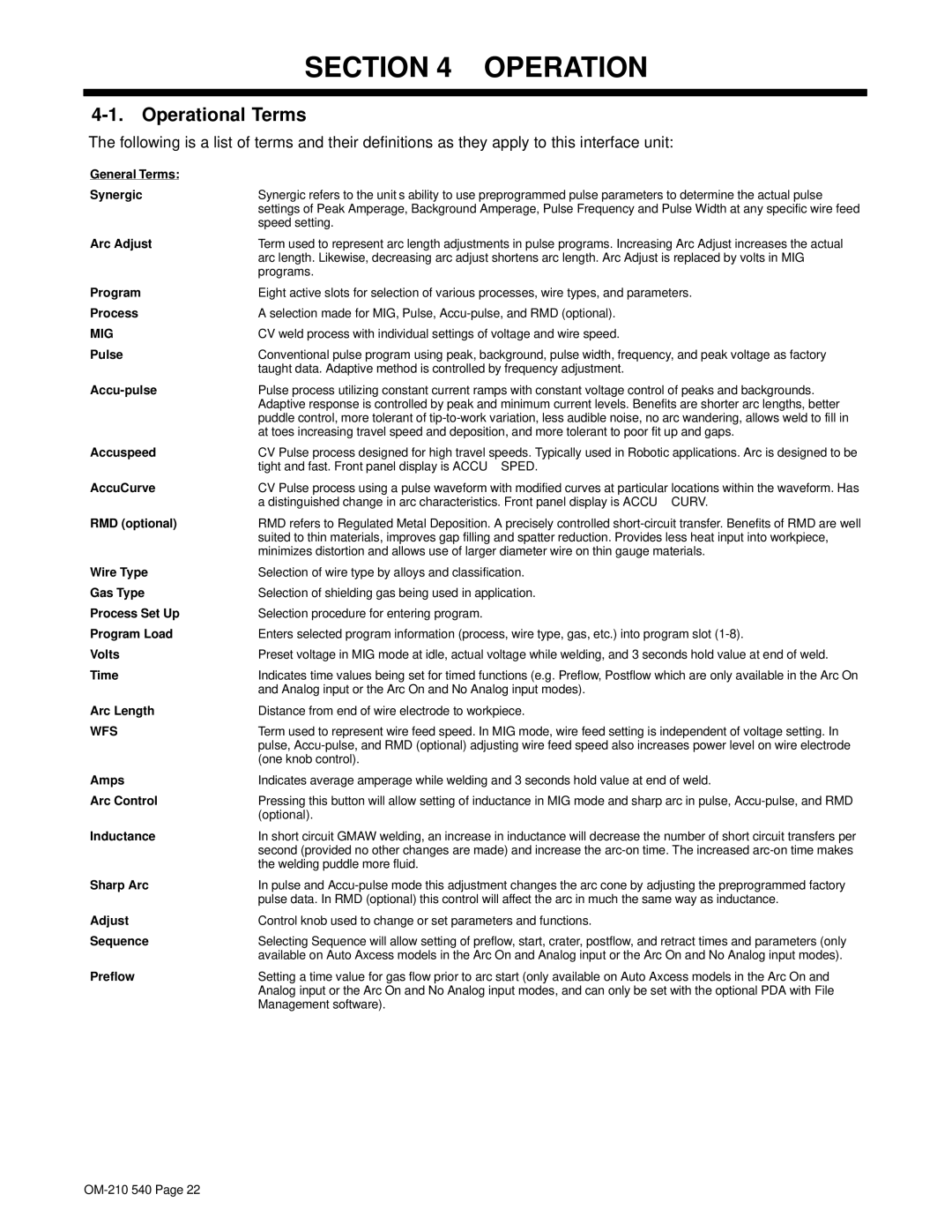

SECTION 4 − OPERATION

4-1. Operational Terms

The following is a list of terms and their definitions as they apply to this interface unit:

General Terms: |

|

Synergic | Synergic refers to the unit’s ability to use preprogrammed pulse parameters to determine the actual pulse |

| settings of Peak Amperage, Background Amperage, Pulse Frequency and Pulse Width at any specific wire feed |

| speed setting. |

Arc Adjust | Term used to represent arc length adjustments in pulse programs. Increasing Arc Adjust increases the actual |

| arc length. Likewise, decreasing arc adjust shortens arc length. Arc Adjust is replaced by volts in MIG |

| programs. |

Program | Eight active slots for selection of various processes, wire types, and parameters. |

Process | A selection made for MIG, Pulse, |

MIG | CV weld process with individual settings of voltage and wire speed. |

Pulse | Conventional pulse program using peak, background, pulse width, frequency, and peak voltage as factory |

| taught data. Adaptive method is controlled by frequency adjustment. |

| Pulse process utilizing constant current ramps with constant voltage control of peaks and backgrounds. |

| Adaptive response is controlled by peak and minimum current levels. Benefits are shorter arc lengths, better |

| puddle control, more tolerant of |

| at toes increasing travel speed and deposition, and more tolerant to poor fit up and gaps. |

Accuspeed | CV Pulse process designed for high travel speeds. Typically used in Robotic applications. Arc is designed to be |

| tight and fast. Front panel display is ACCU − SPED. |

AccuCurve | CV Pulse process using a pulse waveform with modified curves at particular locations within the waveform. Has |

| a distinguished change in arc characteristics. Front panel display is ACCU − CURV. |

RMD (optional) | RMD refers to Regulated Metal Deposition. A precisely controlled |

| suited to thin materials, improves gap filling and spatter reduction. Provides less heat input into workpiece, |

| minimizes distortion and allows use of larger diameter wire on thin gauge materials. |

Wire Type | Selection of wire type by alloys and classification. |

Gas Type | Selection of shielding gas being used in application. |

Process Set Up | Selection procedure for entering program. |

Program Load | Enters selected program information (process, wire type, gas, etc.) into program slot |

Volts | Preset voltage in MIG mode at idle, actual voltage while welding, and 3 seconds hold value at end of weld. |

Time | Indicates time values being set for timed functions (e.g. Preflow, Postflow which are only available in the Arc On |

| and Analog input or the Arc On and No Analog input modes). |

Arc Length | Distance from end of wire electrode to workpiece. |

WFS | Term used to represent wire feed speed. In MIG mode, wire feed setting is independent of voltage setting. In |

| pulse, |

| (one knob control). |

Amps | Indicates average amperage while welding and 3 seconds hold value at end of weld. |

Arc Control | Pressing this button will allow setting of inductance in MIG mode and sharp arc in pulse, |

| (optional). |

Inductance | In short circuit GMAW welding, an increase in inductance will decrease the number of short circuit transfers per |

| second (provided no other changes are made) and increase the |

| the welding puddle more fluid. |

Sharp Arc | In pulse and |

| pulse data. In RMD (optional) this control will affect the arc in much the same way as inductance. |

Adjust | Control knob used to change or set parameters and functions. |

Sequence | Selecting Sequence will allow setting of preflow, start, crater, postflow, and retract times and parameters (only |

| available on Auto Axcess models in the Arc On and Analog input or the Arc On and No Analog input modes). |

Preflow | Setting a time value for gas flow prior to arc start (only available on Auto Axcess models in the Arc On and |

| Analog input or the Arc On and No Analog input modes, and can only be set with the optional PDA with File |

| Management software). |