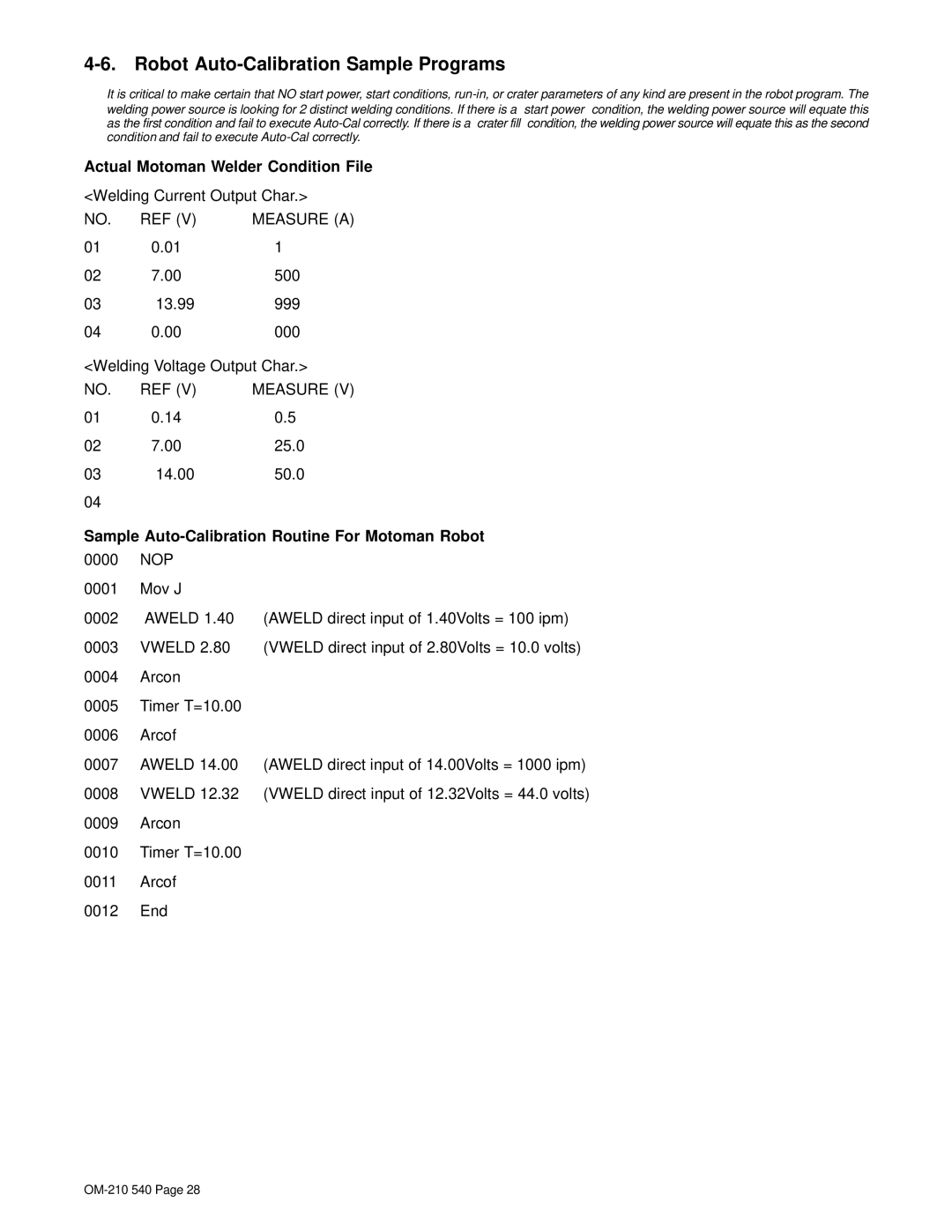

4-6. Robot Auto-Calibration Sample Programs

.It is critical to make certain that NO start power, start conditions,

Actual Motoman Welder Condition File

<Welding Current Output Char.>

NO. | REF (V) | MEASURE (A) |

01 | 0.01 | 1 |

02 | 7.00 | 500 |

03 | 13.99 | 999 |

04 | 0.00 | 000 |

<Welding Voltage Output Char.> | ||

NO. | REF (V) | MEASURE (V) |

01 | 0.14 | 0.5 |

02 | 7.00 | 25.0 |

03 | 14.00 | 50.0 |

04 |

|

|

Sample | ||

0000 | NOP |

|

0001 | Mov J |

|

0002 | AWELD 1.40 (AWELD direct input of 1.40Volts = 100 ipm) | |

0003 | VWELD 2.80 | (VWELD direct input of 2.80Volts = 10.0 volts) |

0004 | Arcon |

|

0005 | Timer T=10.00 |

|

0006 | Arcof |

|

0007 | AWELD 14.00 (AWELD direct input of 14.00Volts = 1000 ipm) | |

0008 | VWELD 12.32 (VWELD direct input of 12.32Volts = 44.0 volts) | |

0009 | Arcon |

|

0010 | Timer T=10.00 |

|

0011 | Arcof |

|

0012 | End |

|