7.6Adjusting Engine Speed

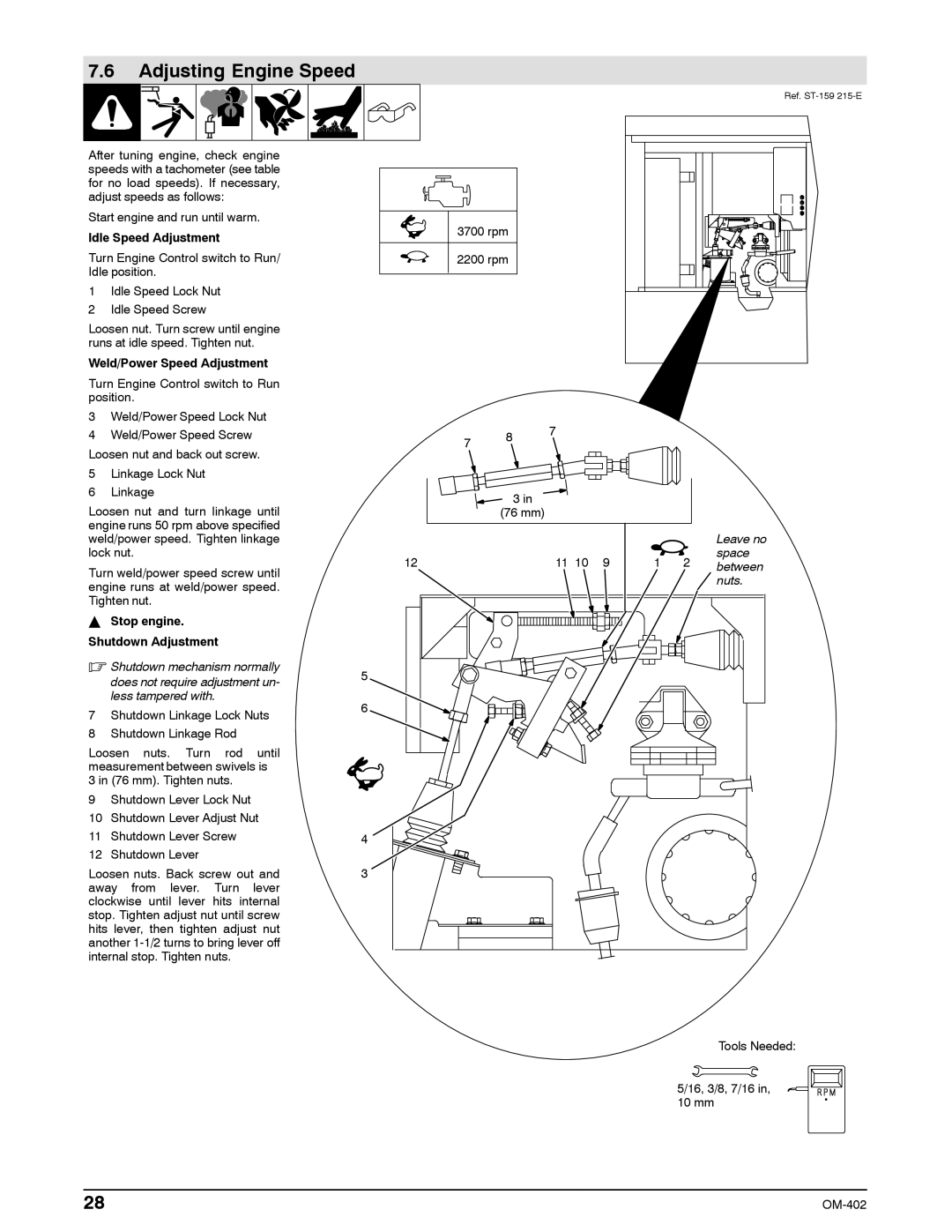

After tuning engine, check engine speeds with a tachometer (see table for no load speeds). If necessary, adjust speeds as follows:

Ref.

Start engine and run until warm.

Idle Speed Adjustment

Turn Engine Control switch to Run/ Idle position.

1Idle Speed Lock Nut

2Idle Speed Screw

Loosen nut. Turn screw until engine runs at idle speed. Tighten nut.

Weld/Power Speed Adjustment

Turn Engine Control switch to Run position.

3Weld/Power Speed Lock Nut

4Weld/Power Speed Screw Loosen nut and back out screw.

5Linkage Lock Nut

6Linkage

Loosen nut and turn linkage until engine runs 50 rpm above specified weld/power speed. Tighten linkage lock nut.

Turn weld/power speed screw until engine runs at weld/power speed. Tighten nut.

YStop engine. Shutdown Adjustment

.Shutdown mechanism normally

does not require adjustment un- less tampered with.

7Shutdown Linkage Lock Nuts

8Shutdown Linkage Rod

Loosen nuts. Turn rod until measurement between swivels is 3 in (76 mm). Tighten nuts.

9Shutdown Lever Lock Nut

10Shutdown Lever Adjust Nut

11Shutdown Lever Screw

12Shutdown Lever

Loosen nuts. Back screw out and away from lever. Turn lever clockwise until lever hits internal stop. Tighten adjust nut until screw hits lever, then tighten adjust nut another

3700 rpm

2200 rpm

7 8 7

![]() 3 in

3 in ![]() (76 mm)

(76 mm)

12 | 11 10 | 9 |

5

6

4

3

|

| Leave no |

1 | 2 | space |

between |

![]() nuts.

nuts.

Tools Needed:

5/16, 3/8, 7/16 in, 10 mm

28 |