INSTALLATION AND WIRING

2.2.3 Wiring of the control circuit

(1) Wiring instructions

1)Terminals SD, SE and 5 are common to the I/O signals and isolated from each other. These common terminals must not be connected to each other or earthed.

2)Use shielded or twisted cables for connection to the control circuit terminals and run them away from the main and power circuits (including the 200V relay sequence circuit).

3)The frequency input signals to the control circuit are micro currents. When contacts are required, use two or more parallel micro signal contacts or a twin contact to prevent a contact fault.

4)It is recommended to use the cables of 0.75mm2 gauge for connection to the control circuit terminals.

If the cable gauge used is 1.25mm2 or more, the front cover may be lifted when there are many cables running or the cables are run improperly, resulting in an operation panel or parameter unit contact fault.

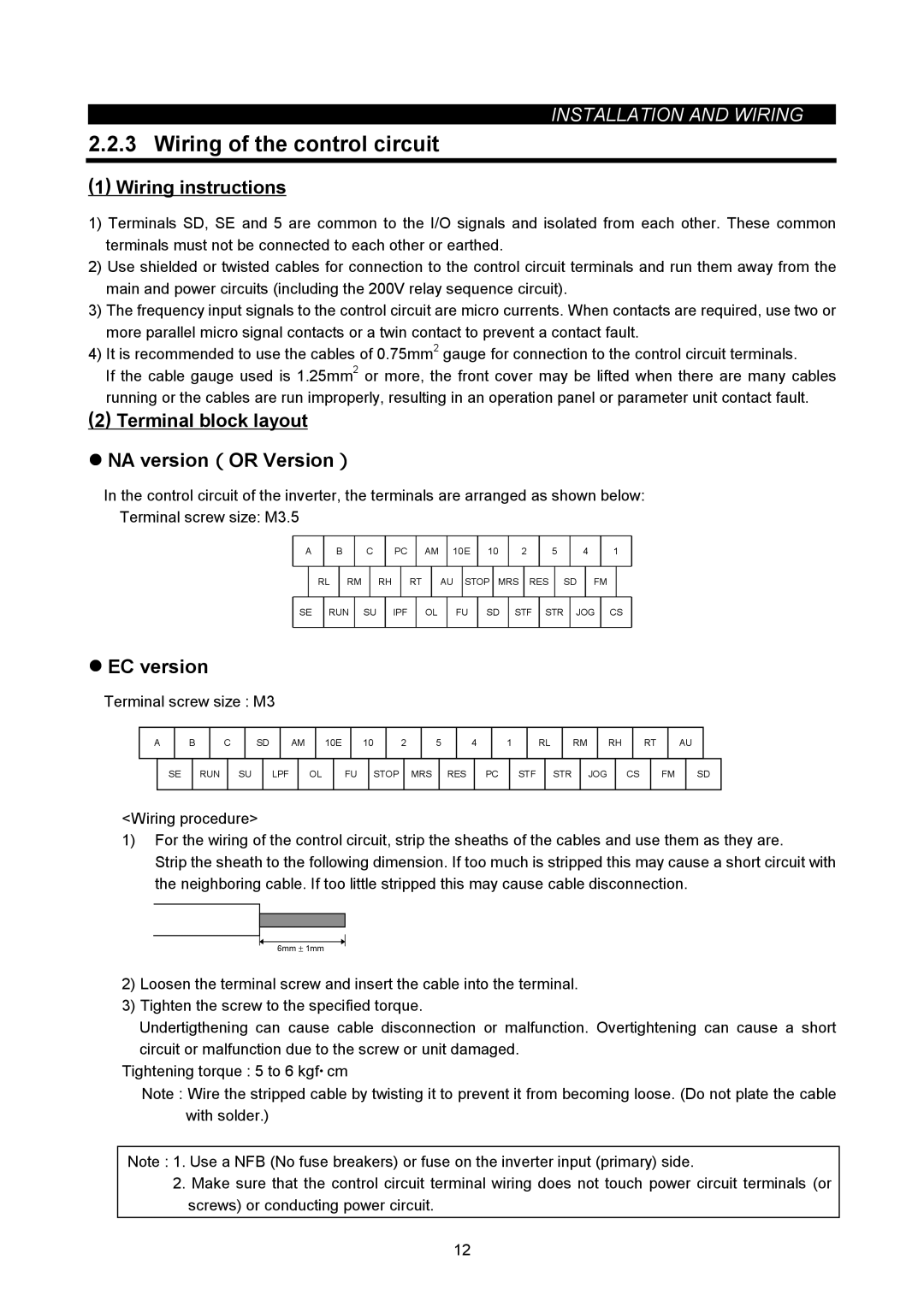

(2) Terminal block layout

zNA version(OR Version)

In the control circuit of the inverter, the terminals are arranged as shown below:

Terminal screw size: M3.5

A |

| B |

| C |

| PC |

| AM |

| 10E | 10 | 2 | 5 |

| 4 |

| 1 | |||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| RL | RM |

| RH |

| RT |

|

| AU | STOP | MRS | RES |

| SD | FM |

|

| ||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

SE |

| RUN |

| SU |

| IPF |

| OL |

| FU | SD | STF | STR |

| JOG |

| CS | |||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

zEC version

Terminal screw size : M3

A

B

C

SD

AM 10E 10

2

5

4

1

RL RM RH RT AU

SE

RUN SU

LPF OL FU STOP MRS RES

PC

STF STR JOG CS FM SD

<Wiring procedure>

1)For the wiring of the control circuit, strip the sheaths of the cables and use them as they are.

Strip the sheath to the following dimension. If too much is stripped this may cause a short circuit with the neighboring cable. If too little stripped this may cause cable disconnection.

6mm ± 1mm

2)Loosen the terminal screw and insert the cable into the terminal.

3)Tighten the screw to the specified torque.

Undertigthening can cause cable disconnection or malfunction. Overtightening can cause a short

circuit or malfunction due to the screw or unit damaged. Tightening torque : 5 to 6 kgf・cm

Note : Wire the stripped cable by twisting it to prevent it from becoming loose. (Do not plate the cable with solder.)

Note : 1. Use a NFB (No fuse breakers) or fuse on the inverter input (primary) side.

2.Make sure that the control circuit terminal wiring does not touch power circuit terminals (or screws) or conducting power circuit.

12