5.2Troubleshooting

PROTECTIVE FUNCTIONS

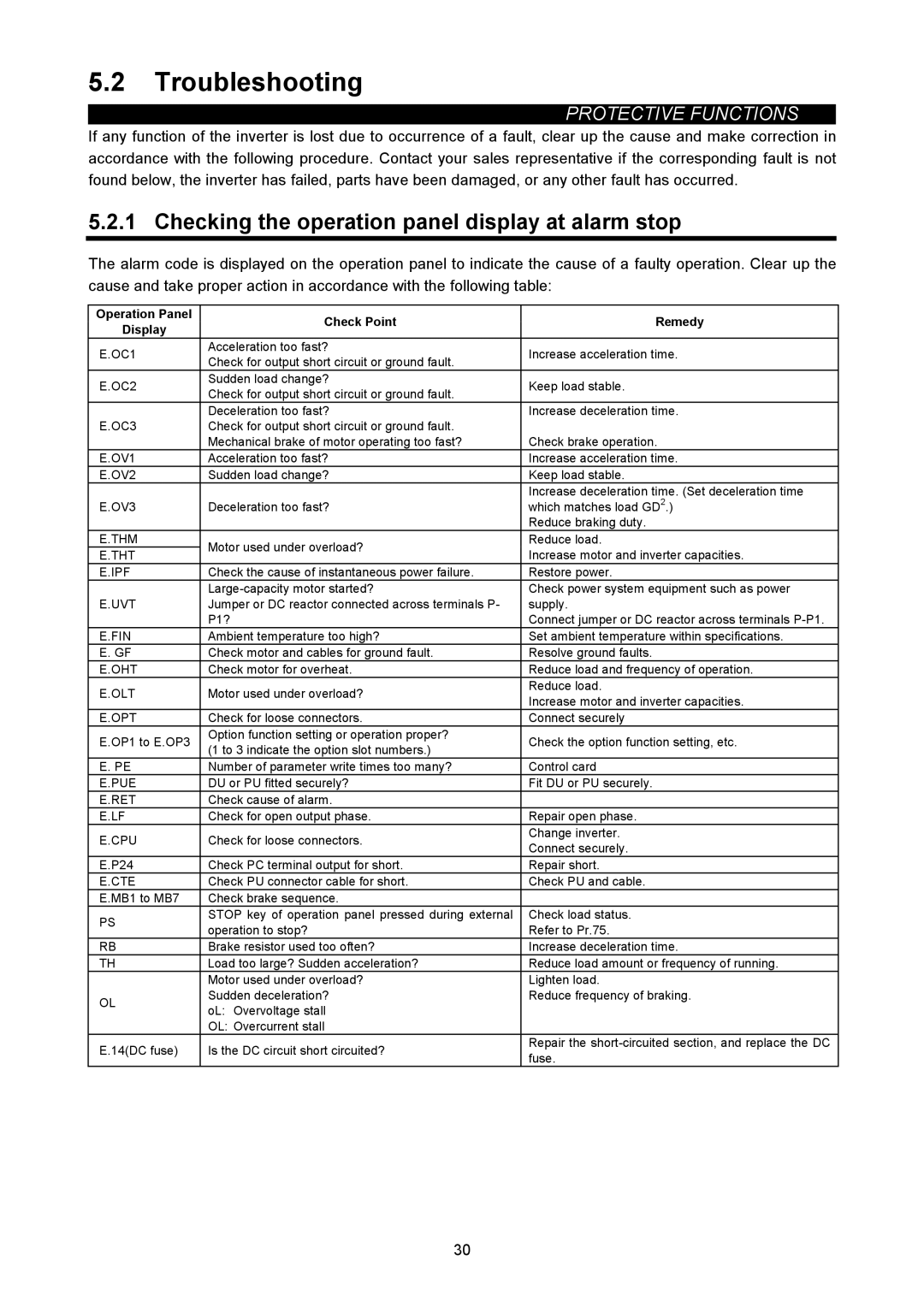

If any function of the inverter is lost due to occurrence of a fault, clear up the cause and make correction in accordance with the following procedure. Contact your sales representative if the corresponding fault is not found below, the inverter has failed, parts have been damaged, or any other fault has occurred.

5.2.1 Checking the operation panel display at alarm stop

The alarm code is displayed on the operation panel to indicate the cause of a faulty operation. Clear up the cause and take proper action in accordance with the following table:

Operation Panel | Check Point | Remedy | |

Display | |||

|

| ||

E.OC1 | Acceleration too fast? | Increase acceleration time. | |

Check for output short circuit or ground fault. | |||

|

| ||

E.OC2 | Sudden load change? | Keep load stable. | |

Check for output short circuit or ground fault. | |||

|

| ||

| Deceleration too fast? | Increase deceleration time. | |

E.OC3 | Check for output short circuit or ground fault. |

| |

| Mechanical brake of motor operating too fast? | Check brake operation. | |

E.OV1 | Acceleration too fast? | Increase acceleration time. | |

E.OV2 | Sudden load change? | Keep load stable. | |

|

| Increase deceleration time. (Set deceleration time | |

E.OV3 | Deceleration too fast? | which matches load GD2.) | |

|

| Reduce braking duty. | |

E.THM | Motor used under overload? | Reduce load. | |

E.THT | Increase motor and inverter capacities. | ||

| |||

E.IPF | Check the cause of instantaneous power failure. | Restore power. | |

| Check power system equipment such as power | ||

E.UVT | Jumper or DC reactor connected across terminals P- | supply. | |

| P1? | Connect jumper or DC reactor across terminals | |

E.FIN | Ambient temperature too high? | Set ambient temperature within specifications. | |

E. GF | Check motor and cables for ground fault. | Resolve ground faults. | |

E.OHT | Check motor for overheat. | Reduce load and frequency of operation. | |

E.OLT | Motor used under overload? | Reduce load. | |

Increase motor and inverter capacities. | |||

|

| ||

E.OPT | Check for loose connectors. | Connect securely | |

E.OP1 to E.OP3 | Option function setting or operation proper? | Check the option function setting, etc. | |

(1 to 3 indicate the option slot numbers.) | |||

|

| ||

E. PE | Number of parameter write times too many? | Control card | |

E.PUE | DU or PU fitted securely? | Fit DU or PU securely. | |

E.RET | Check cause of alarm. |

| |

E.LF | Check for open output phase. | Repair open phase. | |

E.CPU | Check for loose connectors. | Change inverter. | |

Connect securely. | |||

|

| ||

E.P24 | Check PC terminal output for short. | Repair short. | |

E.CTE | Check PU connector cable for short. | Check PU and cable. | |

E.MB1 to MB7 | Check brake sequence. |

| |

PS | STOP key of operation panel pressed during external | Check load status. | |

operation to stop? | Refer to Pr.75. | ||

| |||

RB | Brake resistor used too often? | Increase deceleration time. | |

TH | Load too large? Sudden acceleration? | Reduce load amount or frequency of running. | |

| Motor used under overload? | Lighten load. | |

OL | Sudden deceleration? | Reduce frequency of braking. | |

oL: Overvoltage stall |

| ||

|

| ||

| OL: Overcurrent stall |

| |

E.14(DC fuse) | Is the DC circuit short circuited? | Repair the | |

fuse. | |||

|

|

30