HT 1000, JT 1000, MT 2000, MTS 2000, and MTX Series

Page

Safety

Foreword

Contents

Disassembly and Reassembly

Iii

Page

Replacement Parts Ordering

List of Tables

Vii

Related Publications Available Separately

Viii

Model Numbering System

Model Charts Model Programming Flashing, and Cloning

Conventional Systems Radios HT 1000 Models

Model Chart

H01RDH9PA3AN

Conventional Systems Radios JT 1000 and MT 2000 Models

PMUF6500D

Private Systems Radios MTS 2000 Models

A a

Xii

List of Antennas

List of Batteries

Xiii

Maintenance Specifications for VHF Radios

Xiv

Maintenance Specifications for 800MHz Radios

ALC

Glossary

Xvi

PLL

R N I N G

Introduction

Page

Recommended Test Equipment

Recommended Test Equipment

Field Programming

Service Aids and Recommended Tools

Motorola Part no Description Application

Service Aids

Recommended Service Tools

Service Tools

Earlier. If the radio is placed in Test Mode

General Setup

Test Mode

Equipment Initial Control Settings

NO. Description Function Beeps

Test Environments, HT 1000/JT 1000 Radios

Test Frequencies, HT 1000 / JT

Control Head Test Mode, HT 1000/JT 1000 Radios

Page

Page

Test Frequencies, MT 2000, MTS 2000, and MTX Series Radios

Test Environments, MT 2000, MTS 2000, and MTX Series Radios

Test Name Communications Radio Test SET Comments Analyzer

Receiver Performance Checks

Test Communications Radio Test SET Comments Name Analyzer

Transmitter Performance Checks

Power-up Display Codes

Error-Code Displays

Power-up Display Codes

Operational Display Codes

Operational Display Codes

General

Radio Alignment Procedure

Dtmf

Reference Oscillator Alignment

Perform the following procedures in the sequence indicated

Standard Test Modulation 1 kHz Tone

Front-End Pre-Selector VHF/UHF only

Rated Audio

Squelch

Transmitter Power

VHF UHF

Transmit Power Setting

Transmit Deviation Limit

Transmit Deviation Limit

Transmit Deviation Limit Reference

Transceiver Board Identification

Page

TX VCO Crossover Procedure

Dtmf Tuning High Speed Signalling

Signalling Deviation

RX VCO Crossover Procedure

MDC

Signalling Deviation

This Radio Contains STATIC-SENSITIVE

Disassembly and Reassembly

Removing the Battery

Disassembly to Board Level

Separating the Cover From the Chassis

Rotating the Front Cover

Separating Control Top From the Chassis

Removing the RF and Controller Boards

Disassembly of Control Top

Disassembly of Front Cover Assembly

Removing the Keypad/Display Board

Reassembly

Reinstalling the Speaker RetainerMAEPFBracket-22578-A

Page

Seating the Flex

Front Cover Assembly to Chassis

Knobs, Antenna, and Battery

Introduction

Maintenance

Preventive Maintenance

Inspection Cleaning

General

Safe Handling of Cmos Devices

Suffer die-bond delamination and possible

Specific

If neighboring Pbga components are heated

Above 365 degrees F degrees C., they will

Solder Tabs

Page

U t i o n

To Replace an Pbga compo- nent

Thin Small Outline Package Tsop Components

Shields

Removing and Replacing

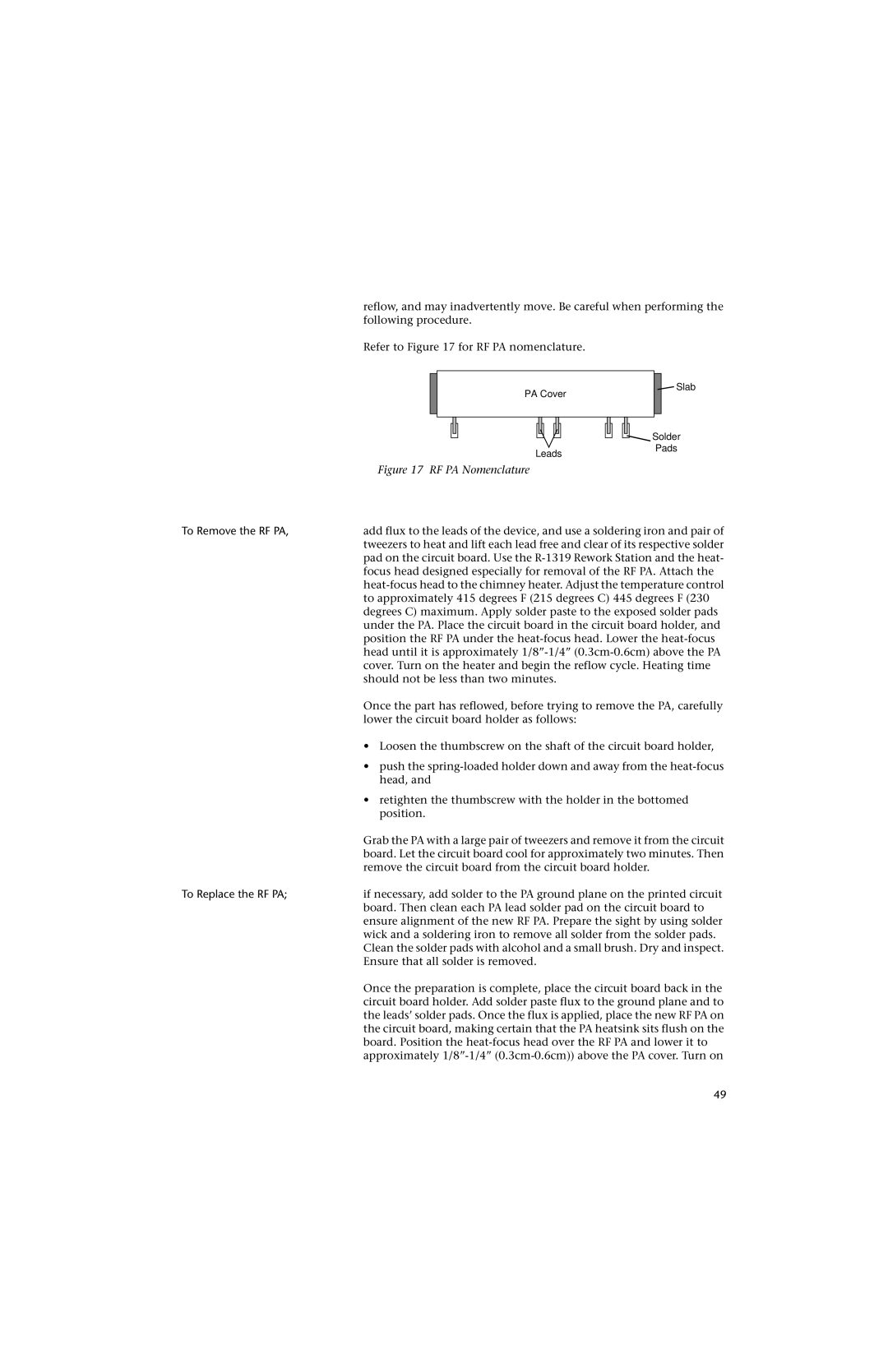

To Replace the RF PA

To Remove the RF PA

Page

Exploded Views

Refer to electrical parts list transceiver board

Top-Display Radios

Keypad Radios

SHIELD, PA

Uni-board Radios

Page

Circuit Board Layers

Transceiver Controller Schematic and Circuit Board Notes

SYN

Integrated Circuit Details with Pin-Out Names

35U50 X Wlyww

Wlyww

Universal Connector Option Select OPT SEL Definition

Universal Connector Pin Numbers and Signal Assignments

MAEPF-2

Fuse 1-Amp

CAPACITOR, Fixed pF ± 5%

Unless stated

Diode See Note

U102

BATT+

Error Feedback

NC NC NC NC CLK

5VREG SB+

MAEPF-2630

0625W unless stated

CAPACITOR, Fixed pF ±30%

Transistor See Note

RESISTOR, Fixed Ω ± 5%

DAC CLK

Switch

Connector EXT. ANT

These Levels Measured by Removing R52

Batt

NC NC NC NC NC CLK

DET VDD VDD2

Cext

MAEPF-2630

COIL, RF nH

CAPACITOR, Fixed pF ± 25%

50V unless stated

GND1 GND2 GND3 GND4 GND5

RF Switch

CR6 CR7 CR8 CR9

ABP GND1 GND2 GND3 AG2

VMULT2 Frefout

VDD VDD2

DET

NC3 NC4 NC5 NC6 NC7 NC8 NC9

MAEPF-26305

RESISTOR, Fixed Ω ± 0.0625W

3Pack.xls CAPACITOR, Fixed pF ± 5% Sheet Unless stated

U105 U104

SYN SEL

5VREG LCK

VCO MOD RAW B+

LCK SW B+

Transceiver Board Parts List and Component Location Diagrams

DIODE, Zener See Note 1

CAPACITOR, Fixed pF ±5%

Fuse 1.0A Filter See Note 2, 73.35MHZ

RESISTOR, FixedΩ ± 5% .0625W unless stated

U101

GND30

CLK Batt

GND32

GND31

NUF6499B/C and NUF6502B/C 900MHz

Diode

U105

GND21

SYN SYN SEL

GND30 REF OSC

GND27

NUF/PMUF6499D 900MHz

Electrical Parts List, Transceiver 900MHz NUF/PMUF6499D

To Universal Connector

Reset 5V TX 0V RX

ANODE2 Pacntl INT CAP Antswbs Switch

GND GND1 GND2 RF Switch

Synthesizer

Je di HT/JT Tra ns .

DIODE, Zener

Clear

HearClear Option

U701

Hear

Asficsel

Resetb

U702

U708

Volsense NC3 Extspkrsel

SB+ Intspkr Error

Intmic Optenable Spkrcom

Spkrcom Aupaen Extspkr

NC5 NC6 NC7 NC8

U709

U706

Controller BOARD’ Parts List and Component Location Diagram

RESISTOR, Fixed Ω ± 5%

GND10 GND11 GND12 GND13 Gnda

Chact Reset

Busy

GND VEE

Upclk A3 Clke VDD3 VDD4

Vccence Enoe Enwe

SPI RX Data Miso

Power Section

Analog Section SCK

SPI TX Data Mosi

U712

Main Power Switch

Vdd Regulator

Vaud Regulator

MAEPF-25672

DIODE, Zener See Note

103

CAPACITOR, Fixed pF ±

Cpnenab Expout Ffenab Cbufou

Hiclmpen Compen Lcdis Hcidis Ffen

Sqdet Chact Univio Pwrrst Sqdet Chact

Icenab Ffout

Uvcs

UV2CS Bootstrp

VSS4 VSS1 Synsel Roscsel Ascficsel Bootstrp Csgen

Scirx Eecs Muxcntl SEL LED

Extspkr Datalatch Extmic

SWB+ GND1 Blcntl Intspkr Reset Spkrcom Intmic

OPTB+/BOOTSEL Mosi

GND2 Keyint OPTSEL1

NTN7512D/E, NTN7513E, NTN7857D/E and NTN7858D/E 107

MAEPF-26096

RESISTOR, Fixed Ω ± 0.0625W unless stated

109

HearClear Components Not Placed on NCN6176A

CAPACITOR, Fixed pF ± 5% 50V unless stated

Ffcnt L

SWB+ Sqdet Chact

Expin Lodsab Cbufin Expbyp Rssiin

Ffin VAG Nfilin

U705

Digital Section

U702

Main Power Switch Vdd Regulator

Front Cover Display Flex

115

Replacement Parts Ordering

Motorola Online

Mail Orders

116

Telephone Orders

FAX Orders

Parts Identification

Appendix a

Appendix a

Introduction Circuit Description

Appendix . Secure Module

Signal Name Connector Plug Function P1 PIN Number

Troubleshooting Secure Operations

Appendix a . Key Variable Loader

Service Aid Retrofit Instructions

Set XL IC Present Field

Anti-static precautions must be observed at all times

General

Set Secure-Equipped Field

Channels

Secure Alignment Procedure

Enable Secure On Desired

Secure Retrofit Tuning

Appendix a . Secure Deviation

Compensation

Removal

Removal And Installation

Appendix . Secure Module Location Detail

XL&XL

Appendix a . RSS Secure Parameters

Appendix B

Appendix B

Appendix B . HT 1000 Models

H01RDC9AA1BN

Appendix B . JT 1000 Models

Appendix B . MT 2000 Models

PMUE7272B PMCN6147B

H01SDH9AA7AN

Appendix B . MTS 2000 Models

H01RDD9PW1AN

H01RDH9PW1AN

H01SDH9PW1AN

H01UCH6PW1AN

PMUF6499D Pmcn

Appendix B . MTX Series Models

H01KDF9DB5AN

H01RDD9DB4AN

H01RDH9DB7AN

H01SDH9DB7AN

H01UCC6DF3AN

H01WCC4DB3AN

H01WCH4DB7AN

Page

Motorola, Inc West Sunrise Boulevard Ft. Lauderdale, FL

![]() Slab

Slab