IDEN Digital Multi-Service, Data-Capable Portable

I580

Manual Revisions

Safety and General Information

Electro Magnetic Interference Compatibility

Medical Devices

Accessory Safety Information

Cleaning and Drying Considerations

Safety and General Information

Model Information

Model Numbering System

Model Specifications

General Receiver Transmitter

Contents

Chapter Basic Level Test Modes and Procedures

Chapter Field Level Test Modes and Procedures

Appendix a Ordering Replacement Parts and Kits

Preface

Who Should Use This Manual

How This Manual Is Organized

Conventions Used in This Manual

Related Publications

Overview

IDEN Digital Modulation Technology

Spectrum of iDEN Quad 16QAM

IDEN Voice Compression Technology

RF Transmission Bursts

Calling Area Coverage

Bluetooth Wireless System

Global Positioning System GPS Section

MOTOtalk

SIM Cards

Removing and Inserting a SIM Card

To remove a SIM card Figure

Removing a SIM Card

To insert a SIM card Figure

FEATURES, ICONS, and Indicators

I580 Features

Display Icons

Main Menu Icons

Status Icons

Power-Up Sequence

DISPLAYS, MESSAGES, and Alerts

Power-Down Sequence

Self-Test Errors

Self-Test Reset Errors

Messages

Service Messages

Service Messages

Alert Tones

Alert Tones

Alert Tones

Alert Tones

Using the Optional Vibrate Function

Vibrator Settings

To set unit to vibrate for all calls

From the main menu, select Settings 2-Way Radio Alert Type

Preparing for Basic Level Testing

Reference Accessories

Test Equipment

Reference Unit

Reset Condition

Basic Level Checks and Self Tests

Customer Care

Test Conditions

Basic-Level Test Checklist

Preventive Maintenance

Basic-Level Test Checklist

To clean the unit takes approximately 3 minutes

Mechanical and Electrical Checks

SIM Card Swap Test

Shock and Pressure test time is approximately 3 minutes

SIM Card Swap test time is approximately 5 minutes

Accessory Swap Test

Accessory Swap test time is approximately 5 minutes

Lockup Test

Lockup Test time is approximately 6 minutes

Battery Connections Test

Testing the GPS Receiver

Battery Connections test time is approximately 5 minutes

To test the GPS Receiver

Self-Test Procedures

Voltage Recognition Test

Voltage Recognition test time is approximately 4 minutes

Programming Menu Settings Check

Passcode Test

Passcode test time is approximately 5 minutes

From the main menu, select Settings Display/Info Contrast

Phone Calls Features

Way Radio Options

Volume Features

Security Features

Personalize

From the main menu, select Settings Security GPS PIN

Advanced Features

Call Performance Test

Call Performance test time is approximately 7 minutes

Basic Level Test Modes and Procedures

Entering Debug Mode

To enter Debug/Trace Mode

Test Modes

Trace Mode Display Screens

Display Screens

GPS

Test Mode Test Procedures

Entering Test Mode

To enter Test Mode

Audio Loopback Test

ESN and Imei Matching Test

Debug Check

Audio Loopback test time is approximately 3 minutes

ESN/IMEI Matching test time is approximately 6 minutes

To monitor the data in the unit

68P80401P05

Technician Test Procedures

Connecting the Unit to the RSS Workstation

Programming the i580 Unit

Codeplug Troubleshooting

To access the codeplug Help topic in Windows

Codeplug Help

Preparing for Field Level Testing

Preparing Equipment for Testing

Using RSS

Connecting an iDEN Unit to the R-2660

Typical R-2660 Setup

To connect the unit to the R-2660

To enter Initial Registration mode

Operating the R-2660

RF Zone Fields and Values

Disassembly Sequence Flowchart

Assembly/Disassembly Procedures

Disassembling and Reassembling the Unit

Remove Battery Cover

Install

Remove

Remove Battery

Remove SIM Card

Remove Antenna

Preparing for Field Level Testing Remove Antenna

Remove Back Housing

Remove Main Board, Keypad

Remove Flip Assembly

Procedure to remove flip assembly

Preparing for Field Level Testing Remove Flip Assembly

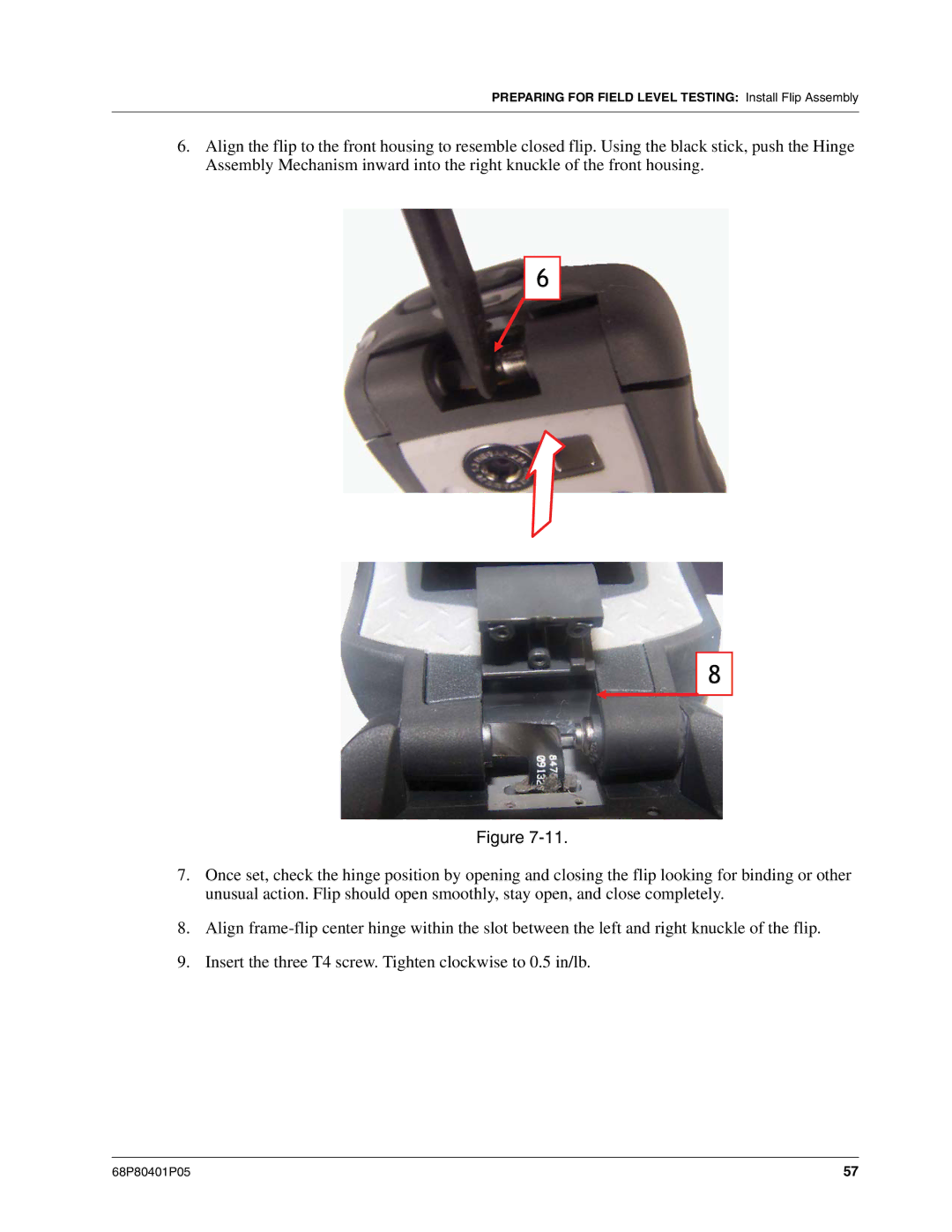

Install Flip Assembly

Procedure to install flip assembly

Preparing for Field Level Testing Install Flip Assembly

Exploded View and Parts List

I580 Component Parts List

I580 Exploded View

Field Level Test Modes and Procedures

Field-Level Test Checklist

Required Test Equipment

Field-Level Test Checklist

Done Technical Tests Pass Fail

See the Strong Signal Environment section

Registration/Call Test

Signal Quality Error SQE Test

R-2660

TX Power Test

See Entering Test Mode Press Menu, Edit

Bit Error Rate BER Test

Pass

Power-Up Test

Keypad Test

Audio Test

Use this test to check the audio portion of the unit

Reset Test

Reset

Reset Log Test

To perform the reset log test

Model Assembly MA Test Mode Test

GPS Global Positioning System Receiver Test

Use this test on a unit to check its GPS functionality

Yes

Bluetooth Test

This Page intentionally left blank

Mechanical Parts Rework and Repair

Recommended Equipment

Recommended Tools

Recommended Supplies

Rework/Repair Requirements

Board Preparation

Components Identification

Mechanical Parts Rework Procedure

Removal Procedure

Land Preparation Procedure

Installation Procedure

4 J600 RF Connector

6 J401 30 Pin Board-to-Flex Connector

5 J752 Audio Jack

7 J400 80 Pin Board-to Flex Connector

8 M002 Simm Connector

9 M105 Battery Contact

SW-all Key/Switch

10 M2 2 Pin-Contact

11 J753 Microphone Socket

13 D401 through D412 LED

Ordering Replacement Parts and Kits

Customer Service

Replacement Parts

Domestic Orders

Replacement Kits

Table A-1

Mid Rate Travel Chargers

Bluetooth Accessories

NNTN2344 NA

Recommended Test Equipment and Tools

Recommended Programming Equipment

Table A-2. Recommended Test Equipment and Tools

Table A-3. Recommended Programming Equipment

Table A-4. Recommended Software

TTY

@68P80401P05@