INITIAL CHECK AND ADJUSTMENTS

PRELIMINARY CHARGE PRESSURE ADJUSTMENT

![]()

![]() NOTICE

NOTICE

Skipping this step during initial

1.Loosen 1-1/16" jam nut on charge relief valve (Item A, Figure 5).

2.Use a 1/2" socket to adjust the small hex nut within the larger hex jam nut (Item B, Figure 5).

3.Rotate small hex nut (Item B, Figure 5) clockwise until bottomed out. DO NOT overtighten.

OIL AND COOLANT CHECK

Hydraulic Oil Check

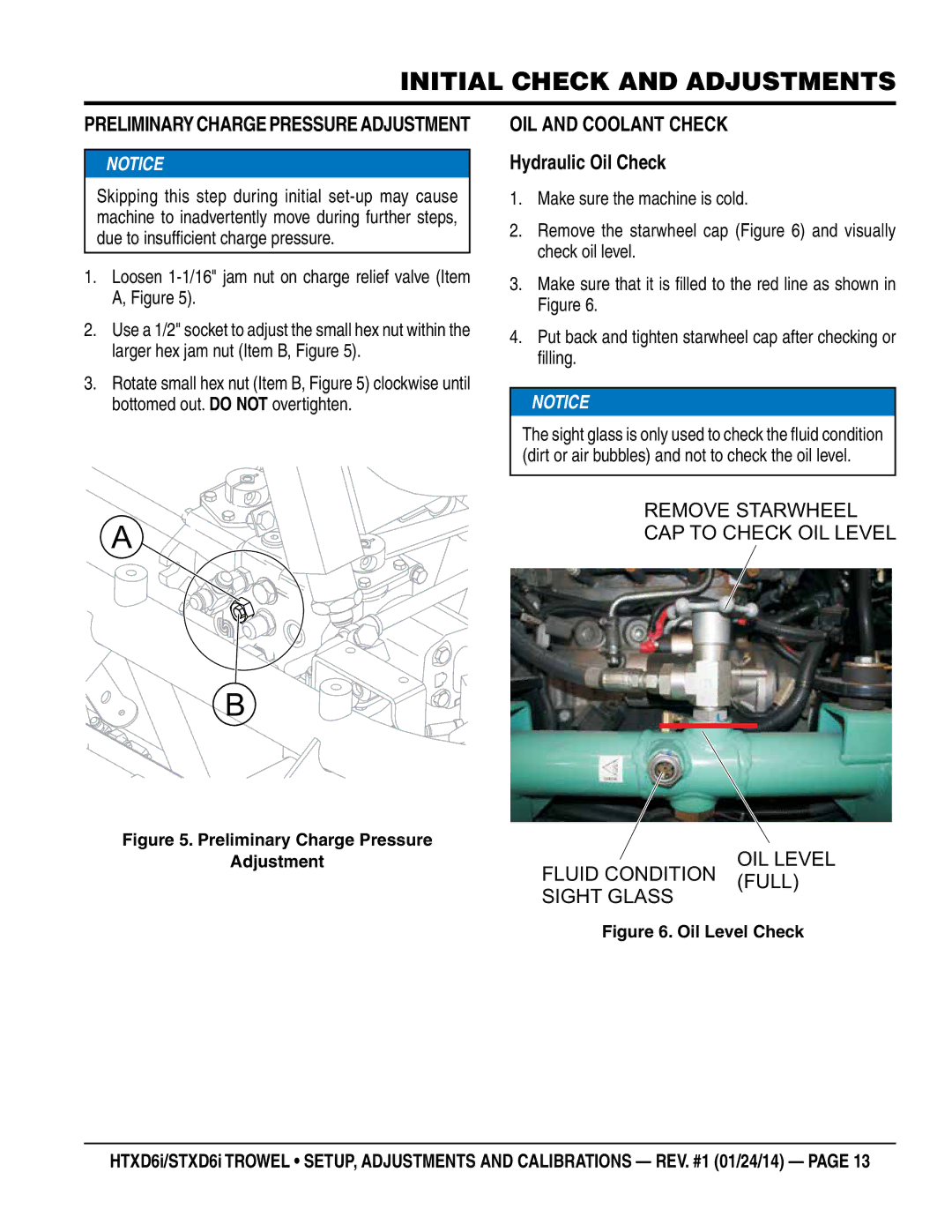

1.Make sure the machine is cold.

2.Remove the starwheel cap (Figure 6) and visually check oil level.

3.Make sure that it is filled to the red line as shown in Figure 6.

4.Put back and tighten starwheel cap after checking or filling.

![]() NOTICE

NOTICE

The sight glass is only used to check the fluid condition (dirt or air bubbles) and not to check the oil level.

A

B

REMOVE STARWHEEL CAP TO CHECK OIL LEVEL

Figure 5. Preliminary Charge Pressure

AdjustmentOIL LEVEL FLUID CONDITION (FULL) SIGHT GLASS

Figure 6. Oil Level Check

HTXD6i/STXD6i TROWEL • SETUP, ADJUSTMENTS AND CALIBRATIONS — REV. #1 (01/24/14) — PAGE 13