INSPECTION

FLUID LEVELS

Record the following fluid levels on Machine Information and Maintenance Log in Inspection section. Refer to Fluid Fill and Check section for procedure.

Engine Oil

Engine Coolant Hydraulic Oil

MECHANICAL

1.Grease Points — Ensure that the following Grease Points are greased, wiped down and capped:

•Thrust Collar

•Fingers

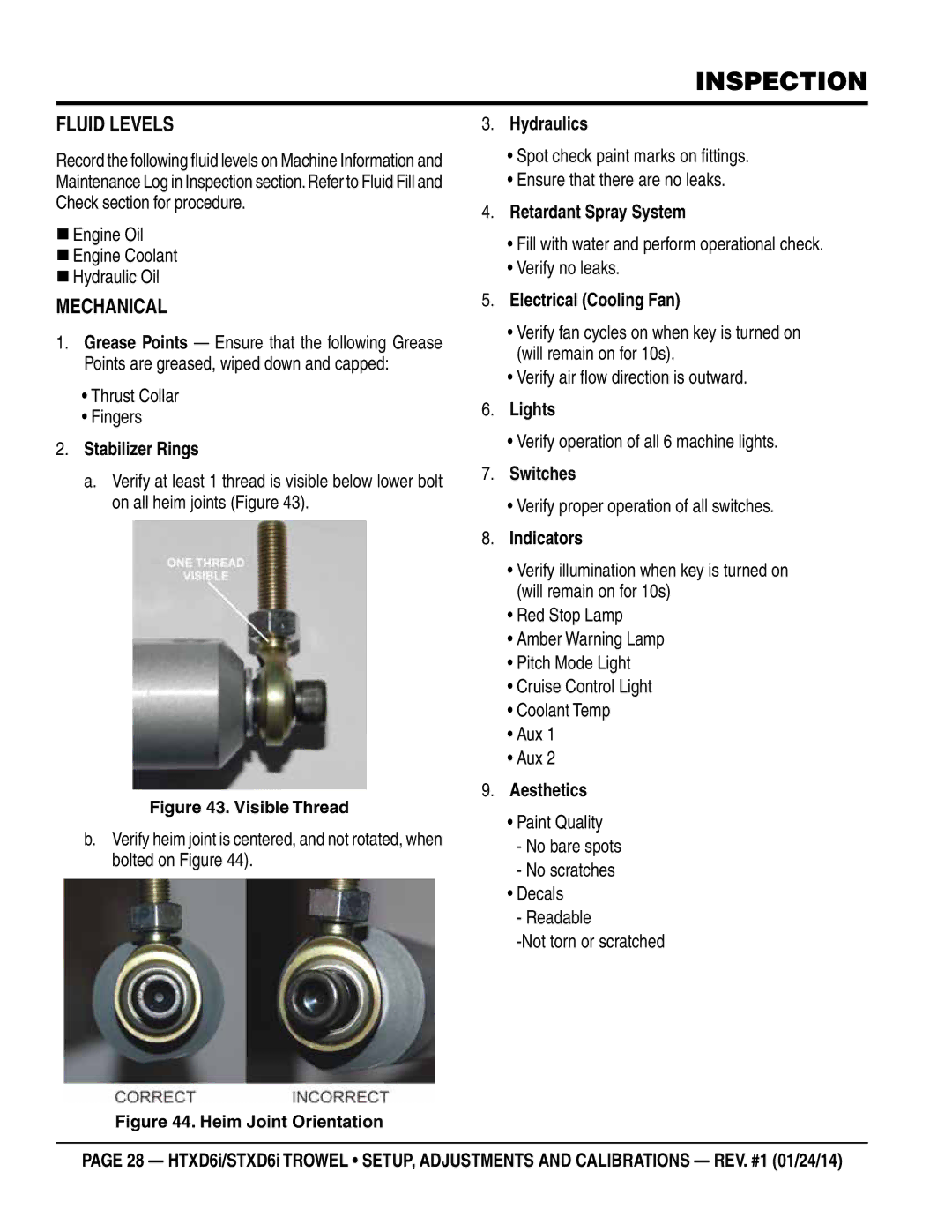

2.Stabilizer Rings

a.Verify at least 1 thread is visible below lower bolt on all heim joints (Figure 43).

Figure 43. Visible Thread

b.Verify heim joint is centered, and not rotated, when bolted on Figure 44).

Figure 44. Heim Joint Orientation

3.Hydraulics

•Spot check paint marks on fittings.

•Ensure that there are no leaks.

4.Retardant Spray System

•Fill with water and perform operational check.

•Verify no leaks.

5.Electrical (Cooling Fan)

•Verify fan cycles on when key is turned on (will remain on for 10s).

•Verify air flow direction is outward.

6.Lights

•Verify operation of all 6 machine lights.

7.Switches

•Verify proper operation of all switches.

8.Indicators

•Verify illumination when key is turned on (will remain on for 10s)

•Red Stop Lamp

•Amber Warning Lamp

•Pitch Mode Light

•Cruise Control Light

•Coolant Temp

•Aux 1

•Aux 2

9.Aesthetics

•Paint Quality

-No bare spots

-No scratches

•Decals

-Readable

PAGE 28 — HTXD6i/STXD6i TROWEL • SETUP, ADJUSTMENTS AND CALIBRATIONS — REV. #1 (01/24/14)