Structural Concrete Pump

Heres HOW to GET Help

Mayco ST-45HRM CE Concrete Pump

ST-45 Pump Specifications

ST-45HRM CE Concrete PUMP- Engine Specifications

ST-45HRM CE Concrete PUMP- Dimensions

ST-45HRM CE Concrete Pump Dimensions

Guaranteed Sound Power Level

EC Declaration of Conformity

ST-45HRM CE Concrete PUMP- Safety Message Alert Symbols

Seriously injured if you do not follow directions

Always wear approved respiratory protection

Instructions Always wear approved eye and hearing protection

Never operate the pump in an explosive

General Safety

ST-45HRM CE Concrete PUMP- Rules for Safe Operation

Transporting

Maintenance Safety

ST-45HRM CE Concrete Pump Rules for Safe Operation

Towing

Battery

Emergencies

ST-45HRM CE Concrete PUMP- Operation and Safety Decals

Machine Safety Decals

ST-45HRM CE Concrete PUMP- Operation and Safety Decals

ST-45HRM CE Concrete PUMP- Operation and Safety Decals

ST-45HRM CE Concrete PUMP- Important Hand Signals

ST-45HRM CE Concrete PUMP- General Information

Concrete Mix Design

Use a minimum

ST-45HRM CE Concrete PUMP- General Information

Regional Differences

ST-45HRM CE Concrete PUMP- HOW IT Works

Pumping Cycle

ST-45HRM CE Concrete PUMP- Pump Components

Major Pump Components

ST-45HRM CE Concrete PUMP- Pump Components

ST-45HRM CE Concrete PUMP- Control BOX Components

ST-45HRM CE Concrete PUMP- Engine Components

Initial Servicing

Getting the concrete to flow through

ST-45HRM CE Concrete PUMP- Operating Procedures

Operating Suggestions

Notremotely

Priming the Pump and Delivery System with Slurry

Pumping Tips

Admixtures

Clearing Concrete Blockage

Reverse Pumping Procedure

Shuttle Tube Inspection Procedure

Carefully knock the end of the hose away from the reducer

Chip the concrete out of the reducer with the pry bar

Nience

Before Starting

ST-45HRM CE Concrete PUMP- Inspection

Fuel Check

Engine OIL Check

Hydraulic Oil

Locate both the left and right rear stabilizer stands

Rear Stabilizer Stand

Pump, set the rear stabilizers as follows

Ignition Switch

ST-45HRM CE Concrete PUMP- Initial START-UP Procedure

Emergency Stop Switch

If any of the status indicator lights

Control Switch

Strokes within 1 minute

Cooling FAN

Engine Speed

Running

Pressure Test

Important Notice! During freezing

Optional Radio Remote Control

Cylinder Lubrication BOX

TiresWear/Inflation

ST-45HRM CE Concrete PUMP-TRAILER Safety Guidelines

Tires/Wheels/Lug Nuts

Lug Nut Torque Requirements

Wheel Lug Nuts Tightening Sequence

ST-45HRM CE Concrete Pump -TOWING Information

Running Gear Manufacturers

ST-45HRM CE Concrete PUMP-TOWING Information

Towing Level

Visual Inspection

It is legal to use safety chains up

ST-45HRM CE Concrete PUMP-TOWING Information

Braking System

It is now possible to begin the setup procedure

ST-45HRM CE Concrete PUMP- Braking System

Brakes

ST-45HRM CE Concrete Pump Braking System

Coupling Andtransmission System

Couplings with Handbrake Mounted on Draw BAR Figures 41F-41J

Adjuster

Greasing Adjustable Joints

CLEANING, Inspecting & Assembly

Inspection

Bearings

Meredith & Eyre Coupling with Bellows and Shaft Nipples

Meredith & Eyre Couplings do not require for

Failure of bond between brake lining

ST-45HRM CE Concrete PUMP- Braking System

Brake lining contaminated with grease

Torque Figures by Application

Application Fastern Size Lbf.ft

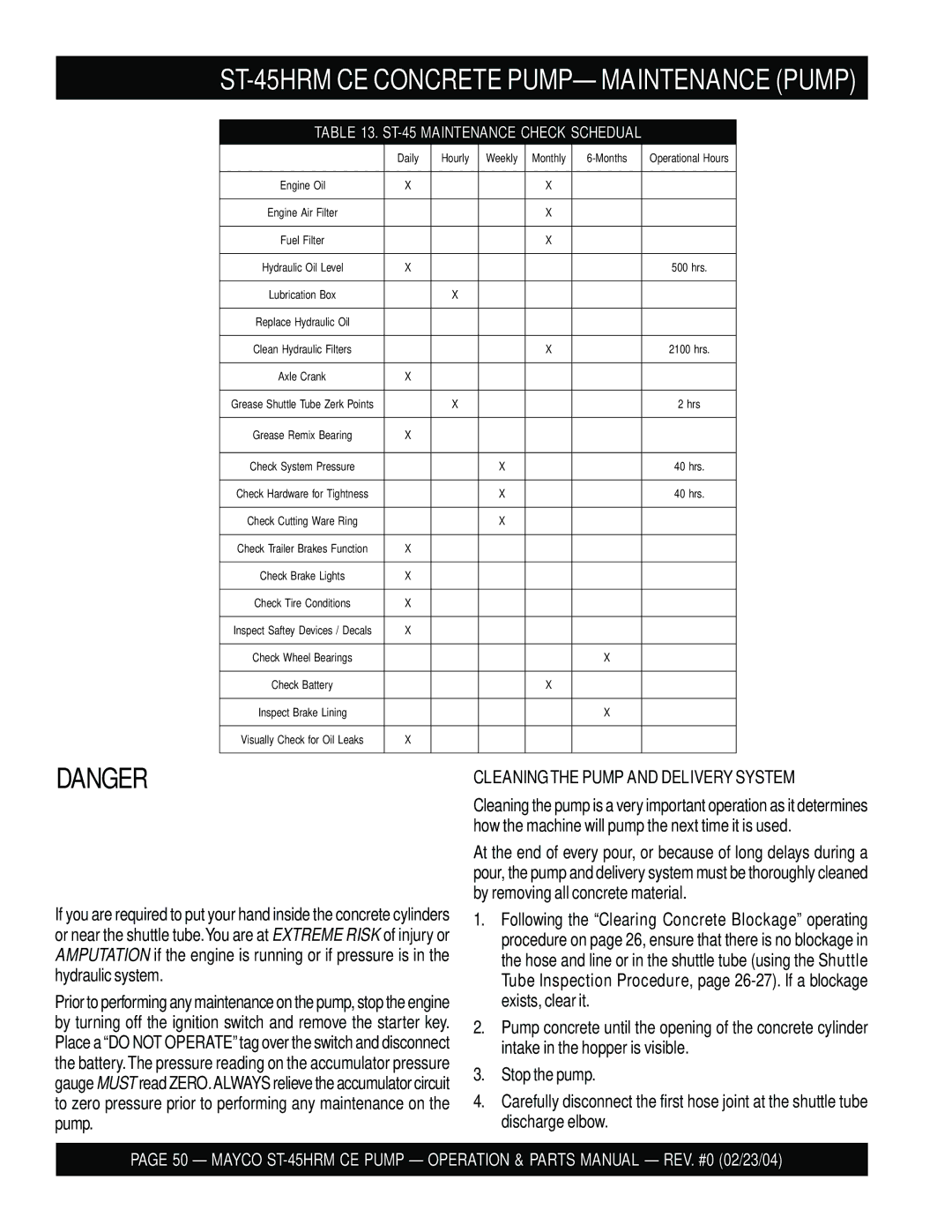

ST-45HRM CE Concrete PUMP- Maintenance Pump

Cleaningthe Pump and Delivery System

Engine Hatz Model 3M41 57 HP Diesel

ST-45HRM CE Concrete PUMP- Maintenance Pump

Hydraulic OIL System Maintenance

Lubricant made for hitch balls

Battery Maintenance

Brake System

ST45 Pressure Setting Sequence

To set maximum pump pressure

Checking Accumulator Bladder Pressure

Cleaningthe Lubrication BOX

ST45 Accumulator Circuit

Pilot Relief Valve Cartridge Adjustment

Size and type of aggregate Type of concrete being pumped

Cylinder CUP Replacement Procedure

Oil prior to installation

Install the two cylinder O rings Hopper Interior Assy, Item

Wear Plate and Ring Replacement Procedure

Wear Plate Installation

Wear Ring installation

Extended Storage Instructions

Emergency Stop Switch Functionaltest

Proximity Switch Functionaltest

ST-45HRM CE Concrete PUMP- Hydraulic Hose Connections

Hydrauilc Hose Connections

ST-45HRM CE Concrete PUMP- Hydraulic Hose Connections

ST-45HRM CE Concrete PUMP- Hydraulic Hose Connections

ST-45HRM CE Manifold Port Locations

Page

Appendix ST-45HRM CE Concrete Pumpconcrete MIX

Appendix ST-45HRM CE Concrete Pump Concrete MIX

Appendix ST-45HRM CE Concrete Pump Slump Test

Slump Test 1/3 Full

ST-45HRM CE Concrete Pump Troubleshooting Engine

Engine Troubleshooting

ST-45HRM CE Concrete PUMP-TROUBLESHOOTING Hydraulic

Hydraulic System Troubleshooting

ST-45HRM CE Concrete PUMP-TROUBLESHOOTING Electrical

Electrical System Troubleshooting

Shotcrete System

Shotcrete System

COUPLING, 3 H-D CF

13 EM23808D Nozzle ASSEMBLY, 2 H-D

Recommended Shotcrete System

10 EM23101 AIR Vibrator Assy TBD

Material has Passedthroughthe Entire Hose Length

Recommended Shotcrete Accessories

Air passages clean

Bushing

AIR Vibrator

AIR Hose

Valve

ST-45HRM CE PUMP- Explanation of Code in Remarks Column

Items Found In the Items Number Column

ST-45HRM CE Suggested Spare Parts

Part numbers on this Suggested

Decal Placement

DECAL, ST-45

DECAL, Maintenance

DECAL, Volume Control TBD DECAL, Shuttle Tube Danger

DECAL, Lubrication BOX

Safety Grids Assy

WASHER, Flat 1/4

GRID, Blade Shaft 4.5 X

WASHER, Lock 1/4 MED

Grid Support Bracket

HUB and Drum Assy

OIL Seal

Stub Axle

Brake

Inner Bearing Cone

Brake Components Assy

Half Shell

Readjustable Wedge

Adjuster Shoe Post

Eyelet

Towing Coupler Assy

BREAK-AWAY Cable TBD Body Assy

Brake Lever Assy

Energy Store

Bellows

ST-45HRM CE Concrete PUMP- Hopper Assy

Hopper Assy

CAP Screw

REMIXER, Shaft

SHAFT, Adaptor

WASHER, Lock 3/8

Hopper Attachment Assy

ST-45HRM CE Concrete PUMP- Hopper Attachment Assy

Tanque Transmission Hatz 57HP Assy

Splash Plate PIN

Splash Plate

Hinge PIN

NUT, HEX 1 NC

Hopper Interior Assy

Wear RING, Hard Faced

Swing Axle Bushing

Shuttle Axle Ring Seal

RING, Insert Steel

Shuttle Cylinder Assy

Tensioner

Thrust Washer

Shuttle CRANK, Splined Shaft

NUT Flex Lock

Fuel and Hydraulic Tank Connections Assy

ST-45HRM CE Concrete PUMP- Fuel and Hydraulictank Assy

Rear Hood Assy

Fuel and Hydraulic Tank Assy

Plug 3/4 Pipe SQ H

ELBOW, Suction

Suction Nipple 3/4

Adapter 1/2- FF- S

Front Cover ASSY.ST-45HRM CE Concrete PUMP- Front Cover Assy

Front Cover Assy

NUT Lock Nyloc 1/4

WASHER, Lock 1/4 Diameter

Document BOX

Heat Exchanger Assy

Heat Exchanger

GUARD, Heat Exchanger

WASHER, Flat 3/8

WASHER, Flat 5/16

Engine and Frame Assy

WASHER, Lock

Connector LINK, Chain

Connector

Shock Mount

ST-45HRM CE Concrete PUMP-THROTTLE and Water Filter Assy

Throttle and Water Filter Assy

Clevis Yoke 1/4

Safety Link Assembly

Bracket

KIT, Solenoid W/BRACKET

Hydraulic Pump Assy

COUPLING, Chain

COUPLING, Engine

Bolt 12 MM X 1 Allen Head

COUPLING, Pump

ST-45HRM CE Concrete PUMP- Lubrication Pistons Assy

Lubrication Pistons Assy

Lubrication BOX

Switch Proximity

Cable Proximity Switch

Plug

Sistema Electrico Hatz Assy

Electrical System Assy

Pump Wire

Connector Boot

Terminal Connector

CABLE, Proximity Switch

Accumulator Assy

Hhcs 3/8 Diameter

Accumulator 1 Gallon

BRACKET, Accumulator

Accumulator Repair KIT

ST-45HRM CE Concrete PUMP- Manifold Assy

Adapter

Test Port

ADAPTOR, Elbow

CARTRIDGE, Pilot Relief

Remixer Control Assy

TEE, Custom

Valve Remix W/LEVER

NUT, HEX 5/16 DIAMETER- NC

Adapter Gauge

Battery Assy

Battery

Battery BOX

Battery HOLD-DOWN Strap

CABLE, Battery Negative

41 in .04 m

ST-45HRM CE Concrete PUMP- Lubrication Panel

Grease Points

HOSE, Plastic TBD HOSE, Steel

Connectoir

HOSE, Plastic

ST-45HRM CE Concrete PUMP- CONTRL. BOX Interior Door Assy

Control BOX Interior Door Assy

RELAY, Large

SWITCH, Emergency Cycle TBD NUT Connector

Relay , Small

SOLENOID, 12 Volt

ST-45HRM CE Concrete PUMP- Control BOX Mounting Assy

Control BOX Mounting Assy

492366 Screw HHC 5/16-18x1-1/2 EM510703

Control BOX Assy

Directional Control Switch

Emergency Stop Switch

Ignition Switch W/ KEY

Pump Control Switch

ST-45HRM CE Concrete PUMP- Control BOX Door Wiring

ST-45HRM CE Concrete PUMP- Control BOX Interiorwiring

ST-45HRM CE Concrete PUMP-TERMINAL Blockwiring Diagram

Page

ST-45HRM CE Concrete PUMP- Control BOX ELECT. Diagram

Sheet 2

TB1

ST-45HRM CE- Hydraulic Diagram

Description Quantity

ST-45HRM CE- Optional Radio Control

ST-45HRM CE-TAIL Lightswiring Diagram

Terms and Conditions of Sale Parts

Freightpolicy

Mechanical Drive Models

Hydraulic Drive Models

Heres HOW to GET Help