Concentric Vent Termination

Concentric vent termination kits are approved for use with these furnaces. The kit part numbers are 904176 (3 inch) and 904177 (2 inch). For proper installation of the concentric vent termina- tion, follow the installation instructions provided with that kit.

Side Wall Vent Kit

This side wall vent kit is approved for use with these furnaces. The kit part number is 904347, and instructions for proper installation are pro- vided with that kit.

DRAINAGE OF CONDENSATE FROM FURNACE

!WARNING:

The condensate produced by the fur- nace must be drained. Do not connect a water supply to the drainage hose of the furnace.

NOTE:The condensate drain should be protected from freezing when in unheated spaces.

The condensate drainage system is internal to the furnace. It is not recommended to connect additional traps to the exterior of the furnace.Do- ing so will have adverse effects on the operation of the furnace.The drain may exit either the right or left side of the furnace cabinet.

The condensate drain can be routed to a flow drain or to a condensate pump. Ensure that the drain

maintains a downward slope from the unit to the drain. Refer to Figure 24 for more details.

For a right side drain simply extend the tubing out of the 7/8” hole in the cabinet, see Figure 21. For a left side drain follow the steps below:

1.Loosen the clamp on the soft exit tube (see Figure 24.)

2.Rotate the soft exit tube (counter clockwise, 180° upflow *RC models; clockwise 90° downflow *RL models.)

3.

4.Route the tubing out of the 7/8” hole located 8 inches up from the bottom furnace.

The condensate should drain from the plastic collector box (location A in Figure 24) as droplets or a small stream. If you notice the furnace has operated for more than 5 minutes without drain- ing or the red status light on the control board is pulsing a

1.Remove the collector box soft tube at loca- tion A in Figure 24 and insure the exit from the collector box is clear of any debris or obstructions.

2.Replace this tube and insure the fit to the header spout is air tight.Air will be drawn into the header if this connection is not tight.

3.Check other tube connections along the drain system. Insure that all are air tight.

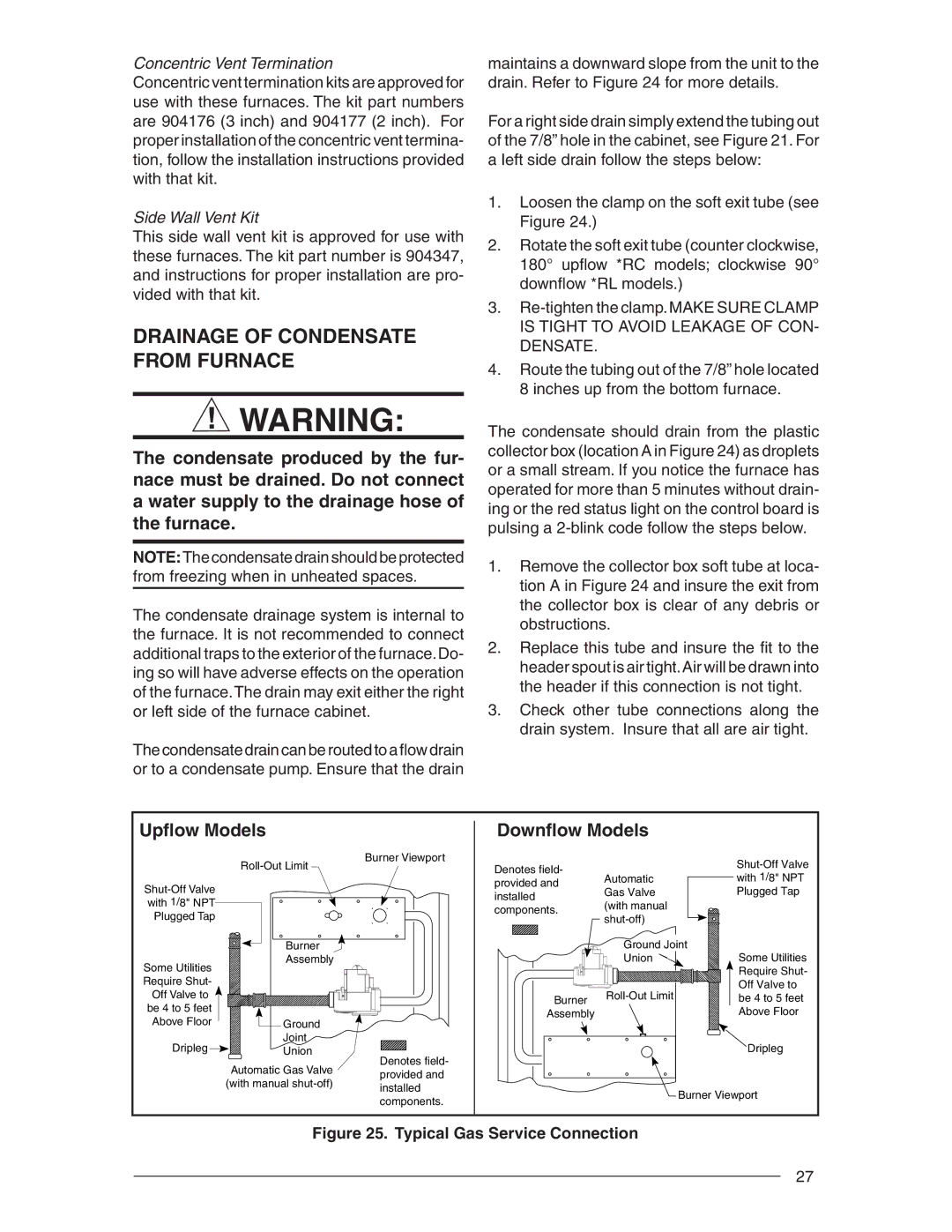

Upflow Models

Burner Viewport

| |

| |

with 1/8" NPT |

|

Plugged Tap |

|

| Burner |

Some Utilities | Assembly |

| |

Require Shut- |

|

Off Valve to |

|

be 4 to 5 feet |

|

Above Floor | Ground |

Dripleg | Joint |

Union |

Denotes field-

Downflow Models

Denotes field-

provided and | Automatic | |

Gas Valve | ||

installed | ||

(with manual | ||

components. | ||

| ||

| Ground Joint | |

| Union | |

Burner |

| |

| ||

Assembly |

|

Some Utilities Require Shut- Off Valve to be 4 to 5 feet Above Floor

Dripleg

Automatic Gas Valve | provided and | |

(with manual | ||

installed | ||

| ||

| components. |

Burner Viewport

Figure 25. Typical Gas Service Connection

27