9-2. Checklist before Servicing

Use a

Diameter of tube D |

| Specification A | |

|

|

| |

Flare tool for R410A |

| Conventional flare tool (for R22) | |

|

| ||

|

|

|

|

Dia.1/4" (6.35 mm) |

|

|

|

| 0 to 0.0196" |

| 0.0472" |

Dia.3/8" (9.52 mm) |

| ||

| (0 to 0.5 mm) |

| (1.2 mm) |

Dia.1/2" (12.7 mm) |

| ||

|

|

|

|

Dia.5/8" (15.88 mm) |

|

|

|

|

|

|

|

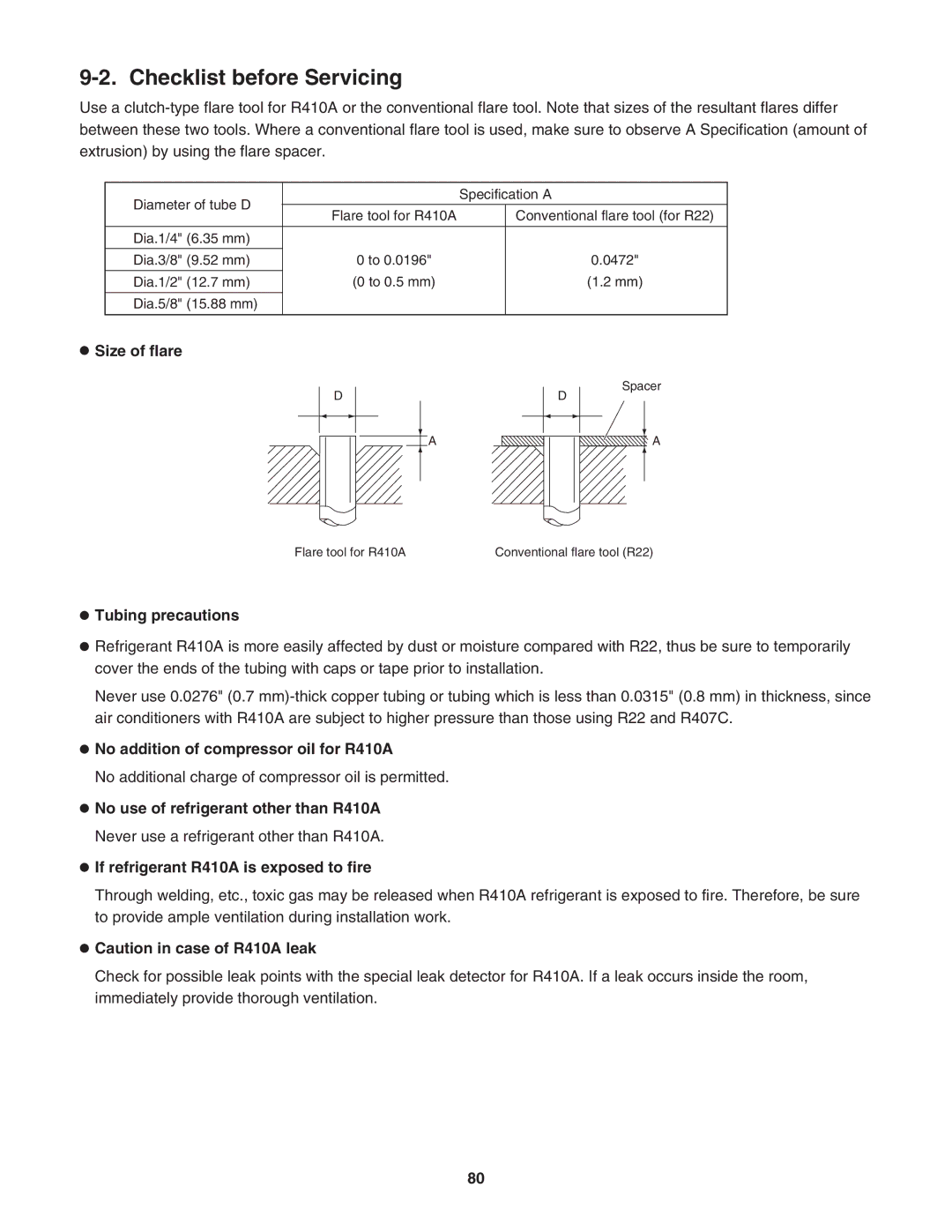

![]() Size of flare

Size of flare

D

A

Spacer |

D |

A |

Flare tool for R410A | Conventional flare tool (R22) |

Tubing precautions

Tubing precautions

![]() Refrigerant R410A is more easily affected by dust or moisture compared with R22, thus be sure to temporarily cover the ends of the tubing with caps or tape prior to installation.

Refrigerant R410A is more easily affected by dust or moisture compared with R22, thus be sure to temporarily cover the ends of the tubing with caps or tape prior to installation.

Never use 0.0276" (0.7

![]() No addition of compressor oil for R410A

No addition of compressor oil for R410A

No additional charge of compressor oil is permitted.

![]() No use of refrigerant other than R410A

No use of refrigerant other than R410A

Never use a refrigerant other than R410A.

If refrigerant R410A is exposed to fire

If refrigerant R410A is exposed to fire

Through welding, etc., toxic gas may be released when R410A refrigerant is exposed to fire. Therefore, be sure to provide ample ventilation during installation work.

![]() Caution in case of R410A leak

Caution in case of R410A leak

Check for possible leak points with the special leak detector for R410A. If a leak occurs inside the room, immediately provide thorough ventilation.

80