Philips Semiconductors

Magnetoresistive sensors for

magnetic field measurement

General

The following general recommendations for operating the KMZ10 can be applied:

∙To ensure stable operation, avoid operating the sensor

in an environment where it is likely to be subjected to negative external fields (‘−Hx’). Preferably, apply a positive auxiliary field (‘Hx’) of sufficient magnitude to prevent any likelihood of flipping within he intended operating range (i.e. the range of ‘Hy’).

∙Before using the sensor for the first time, apply a positive auxiliary field of at least 3 kA/m; this will effectively erase the sensor’s magnetic ‘history’ and will ensure that no residual hysteresis remains (refer to Fig.6).

∙Use the minimum auxiliary field that will ensure stable operation, because the larger the auxiliary field, the lower the sensitivity, but the actual value will depend on

the value of Hd. For the KMZ10B sensor, a minimum auxiliary field of approximately 1 kA/m is recommended;

to guarantee stable operation for all values of Hd, the sensor should be operated in an auxiliary field of 3 kA/m.

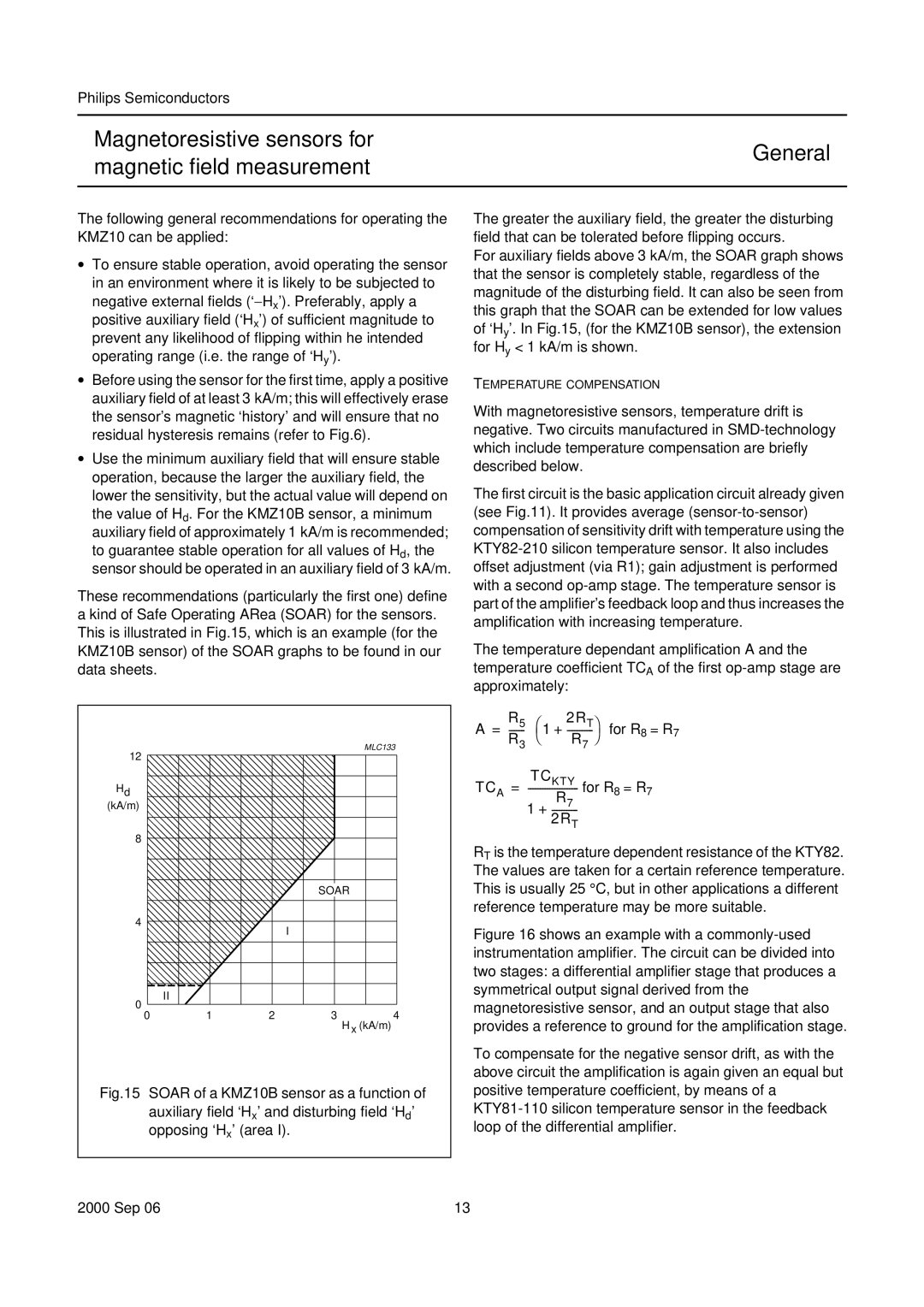

These recommendations (particularly the first one) define a kind of Safe Operating ARea (SOAR) for the sensors. This is illustrated in Fig.15, which is an example (for the KMZ10B sensor) of the SOAR graphs to be found in our data sheets.

12 |

|

|

| MLC133 |

|

|

|

| |

handbook, halfpage |

|

|

|

|

Hd |

|

|

|

|

(kA/m) |

|

|

|

|

8 |

|

|

|

|

|

|

| SOAR |

|

4 |

|

| I |

|

|

|

|

| |

II |

|

|

|

|

0 |

|

|

|

|

0 | 1 | 2 | 3 | 4 |

|

|

| H x (kA/m) | |

Fig.15 SOAR of a KMZ10B sensor as a function of auxiliary field ‘Hx’ and disturbing field ‘Hd’ opposing ‘Hx’ (area I).

The greater the auxiliary field, the greater the disturbing field that can be tolerated before flipping occurs.

For auxiliary fields above 3 kA/m, the SOAR graph shows that the sensor is completely stable, regardless of the magnitude of the disturbing field. It can also be seen from this graph that the SOAR can be extended for low values of ‘Hy’. In Fig.15, (for the KMZ10B sensor), the extension for Hy < 1 kA/m is shown.

TEMPERATURE COMPENSATION

With magnetoresistive sensors, temperature drift is negative. Two circuits manufactured in

The first circuit is the basic application circuit already given (see Fig.11). It provides average

The temperature dependant amplification A and the temperature coefficient TCA of the first

R5 | ⎛ | 2RT⎞ | for R8 | = R7 | |||

A = | ⎝ | 1 + | ⎠ | ||||

R | 3 | R | 7 |

|

| ||

|

|

|

|

|

| ||

| TCKTY | for R8 = R7 | |||||

TCA = | |||||||

| 1 |

| R7 |

|

|

|

|

| + |

|

|

|

| ||

|

|

| 2RT |

|

|

|

|

RT is the temperature dependent resistance of the KTY82. The values are taken for a certain reference temperature. This is usually 25 °C, but in other applications a different reference temperature may be more suitable.

Figure 16 shows an example with a commonly-used instrumentation amplifier. The circuit can be divided into two stages: a differential amplifier stage that produces a symmetrical output signal derived from the magnetoresistive sensor, and an output stage that also provides a reference to ground for the amplification stage.

To compensate for the negative sensor drift, as with the above circuit the amplification is again given an equal but positive temperature coefficient, by means of a

2000 Sep 06 | 13 |