Quarter Panel

Replacement

Installation Procedure

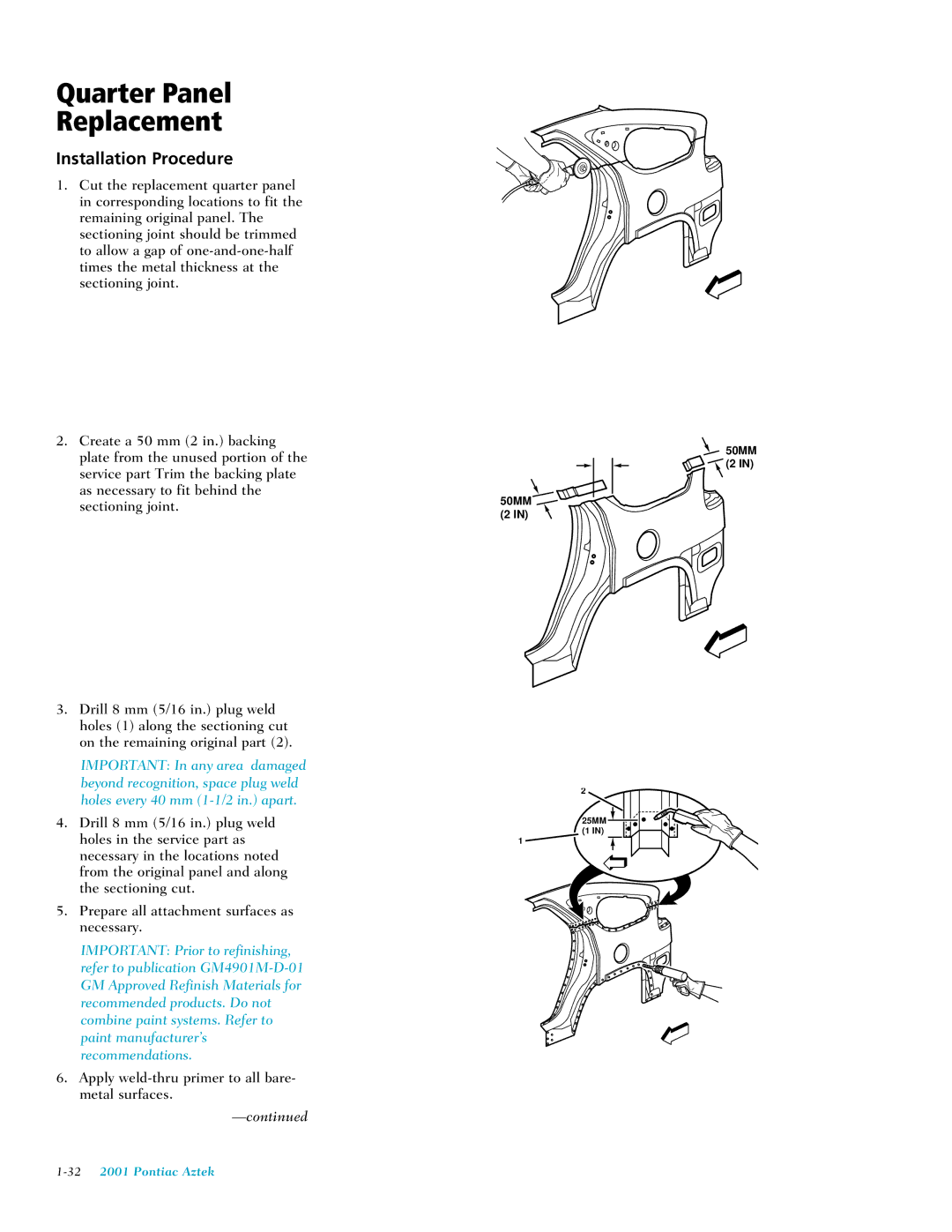

1.Cut the replacement quarter panel in corresponding locations to fit the remaining original panel. The sectioning joint should be trimmed to allow a gap of

2.Create a 50 mm (2 in.) backing plate from the unused portion of the service part Trim the backing plate as necessary to fit behind the sectioning joint.

3.Drill 8 mm (5/16 in.) plug weld holes (1) along the sectioning cut on the remaining original part (2).

IMPORTANT: In any area damaged beyond recognition, space plug weld holes every 40 mm

4.Drill 8 mm (5/16 in.) plug weld holes in the service part as necessary in the locations noted from the original panel and along the sectioning cut.

5.Prepare all attachment surfaces as necessary.

IMPORTANT: Prior to refinishing, refer to publication

6.Apply

50MM  (2 IN)

(2 IN)

50MM (2 IN)

2

25MM ![]()

![]() (1 IN)

(1 IN) ![]()

1