HEAT EXCHANGER REVERSAL PROCEDURE - STANDARD MODELS

1.Remove right and left side access panels (Figure 1).

2.Disconnect wires at high limit, AGS (automatic gas

3.Digital Models: Remove the thermostat tempera- ture sensor by loosening the compression fitting nut (Figure 3).

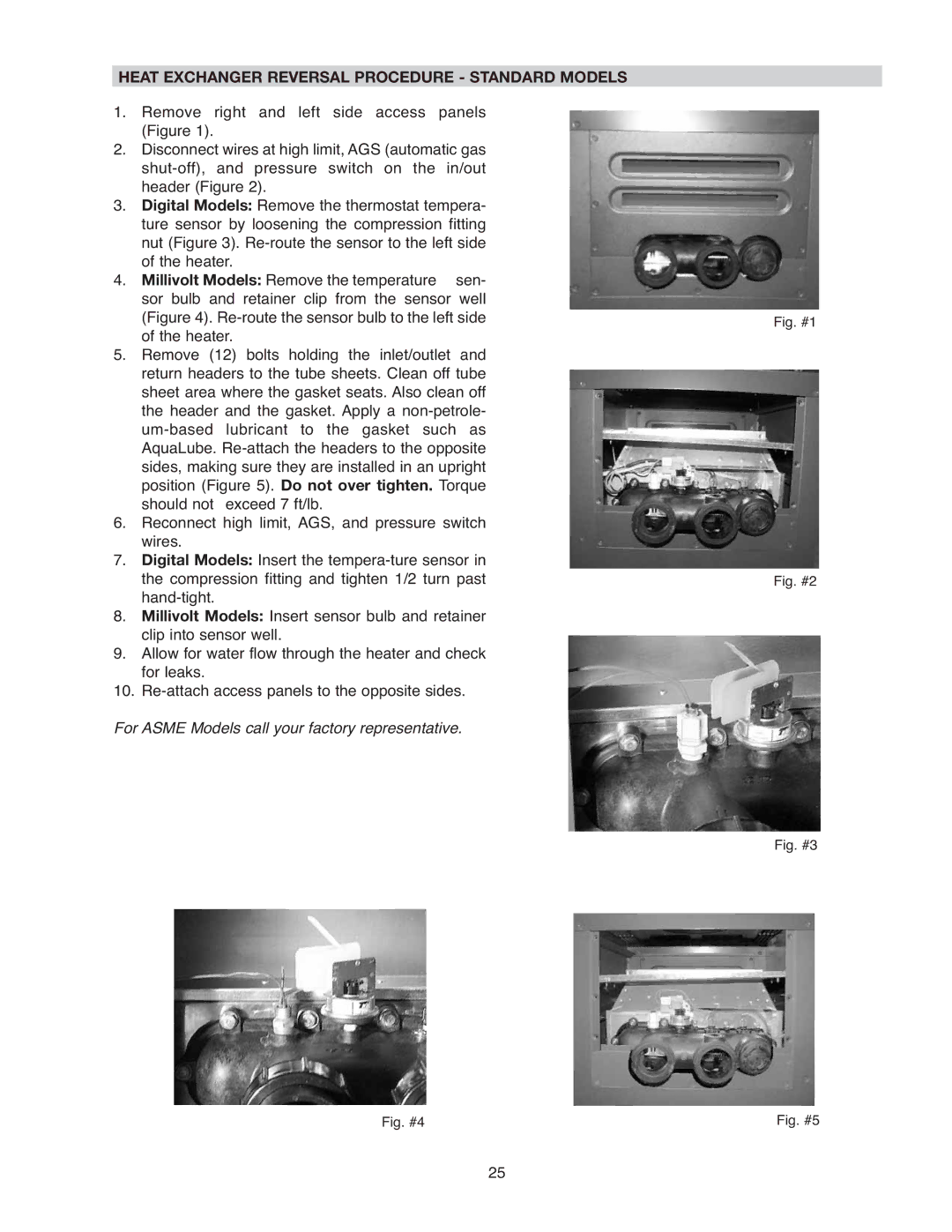

4. Millivolt Models: Remove the temperature sen- sor bulb and retainer clip from the sensor well (Figure 4).

5.Remove (12) bolts holding the inlet/outlet and return headers to the tube sheets. Clean off tube sheet area where the gasket seats. Also clean off the header and the gasket. Apply a

6.Reconnect high limit, AGS, and pressure switch wires.

7.Digital Models: Insert the

8.Millivolt Models: Insert sensor bulb and retainer clip into sensor well.

9.Allow for water flow through the heater and check for leaks.

10.

For ASME Models call your factory representative.

Fig. #4

Fig. #1

Fig. #2

Fig. #3

Fig. #5

25