PLUMBING FOR WATER CONNECTIONS

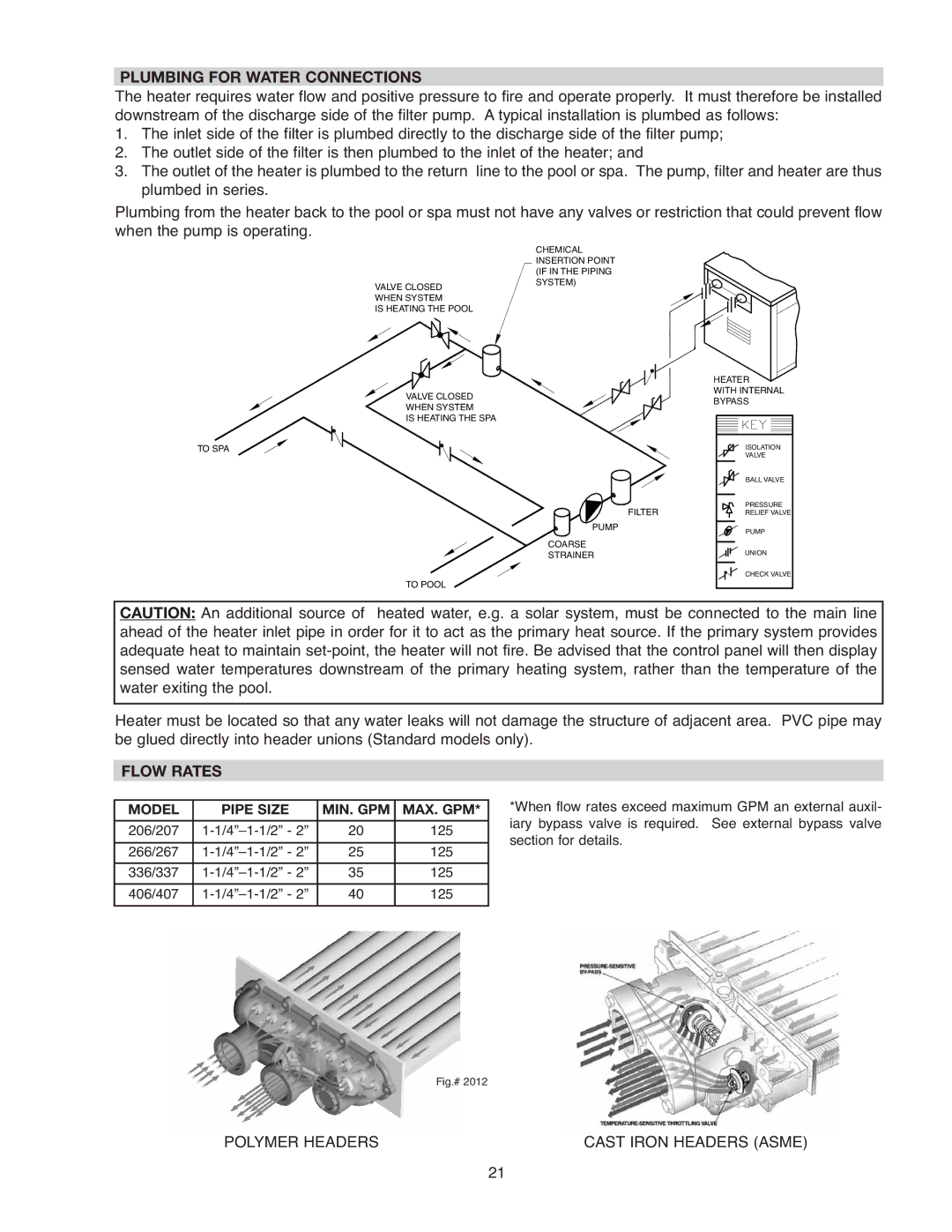

The heater requires water flow and positive pressure to fire and operate properly. It must therefore be installed downstream of the discharge side of the filter pump. A typical installation is plumbed as follows:

1.The inlet side of the filter is plumbed directly to the discharge side of the filter pump;

2.The outlet side of the filter is then plumbed to the inlet of the heater; and

3.The outlet of the heater is plumbed to the return line to the pool or spa. The pump, filter and heater are thus plumbed in series.

Plumbing from the heater back to the pool or spa must not have any valves or restriction that could prevent flow when the pump is operating.

VALVE CLOSED

CHEMICAL INSERTION POINT (IF IN THE PIPING SYSTEM)

WHEN SYSTEM

IS HEATING THE POOL

TO SPA

| HEATER | |

VALVE CLOSED | WITH INTERNAL | |

BYPASS | ||

WHEN SYSTEM | ||

| ||

IS HEATING THE SPA |

| |

| ISOLATION | |

| VALVE | |

| BALL VALVE | |

FILTER | PRESSURE | |

RELIEF VALVE | ||

PUMP | PUMP | |

| ||

COARSE | UNION | |

STRAINER | ||

| CHECK VALVE | |

TO POOL |

|

CAUTION: An additional source of heated water, e.g. a solar system, must be connected to the main line ahead of the heater inlet pipe in order for it to act as the primary heat source. If the primary system provides adequate heat to maintain

Heater must be located so that any water leaks will not damage the structure of adjacent area. PVC pipe may be glued directly into header unions (Standard models only).

FLOW RATES

MODEL | PIPE SIZE | MIN. GPM | MAX. GPM* |

|

|

|

|

206/207 | 20 | 125 | |

|

|

|

|

266/267 | 25 | 125 | |

|

|

|

|

336/337 | 35 | 125 | |

|

|

|

|

406/407 | 40 | 125 | |

|

|

|

|

*When flow rates exceed maximum GPM an external auxil- iary bypass valve is required. See external bypass valve section for details.

Fig.# 2012

POLYMER HEADERS | CAST IRON HEADERS (ASME) |

21