The discharge opening must be a minimum of 2 ft ver- tically from the roof surface and at least 2 ft higher than any part of the building within 10 ft. Vent stack shall be at least 5 ft in vertical height above the drafthood out- let. The vent cap location shall have a minimum clear- ance of 4 ft horizontally from, and in no case below, unless a 4 ft horizontal distance is maintained, from electric meters, gas meters, regulators and relief equipment.

The weight of the vent stack or chimney must not rest on heater drafthood. Support must be provided in compliance with applicable codes. The heater top and drafthood must be readily removable for maintenance and inspection. Vent pipe should be adequately sup- ported to maintain proper clearances from combustible construction.

Type "B"

B149.1 and B149.2).

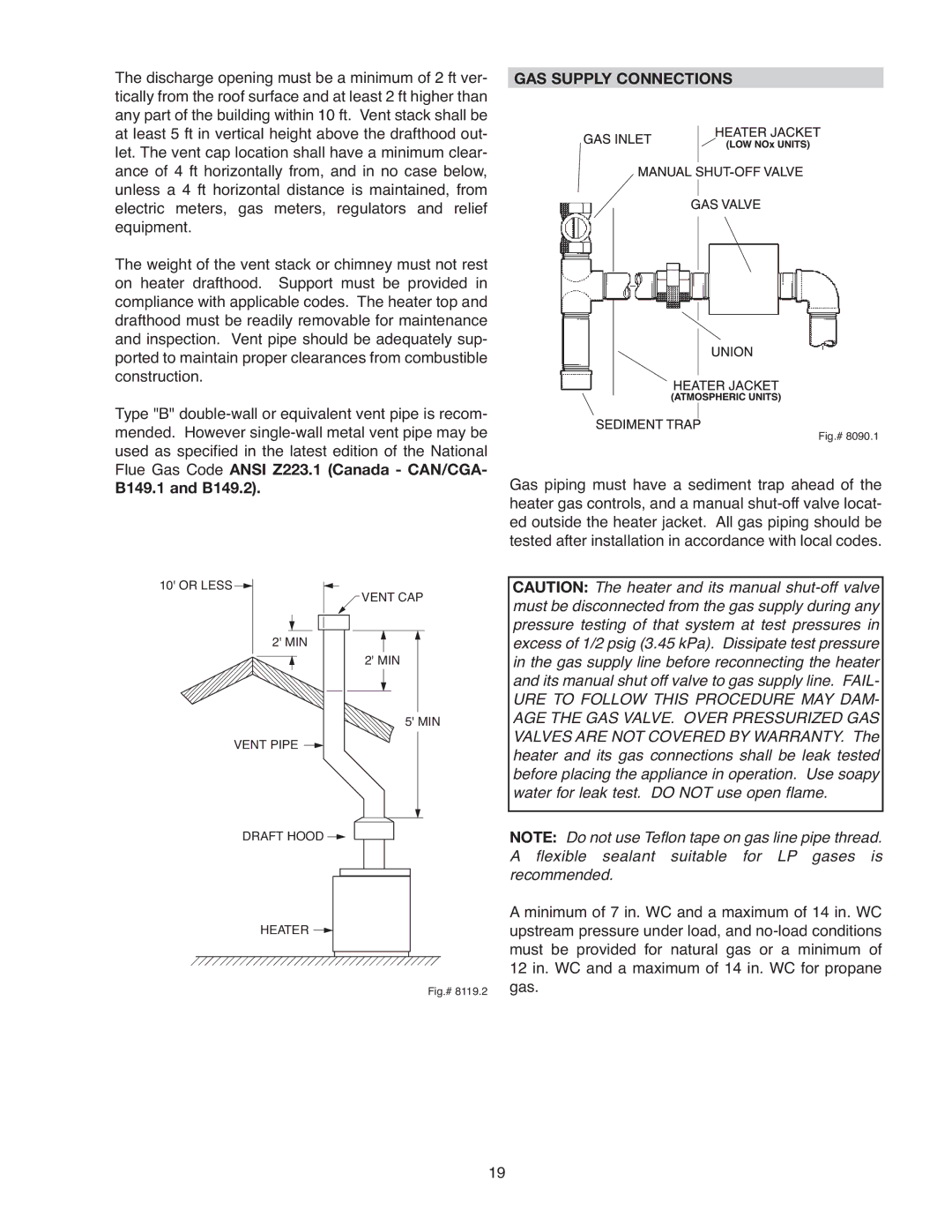

GAS SUPPLY CONNECTIONS

Fig.# 8090.1

Gas piping must have a sediment trap ahead of the heater gas controls, and a manual

10' OR LESS

VENT CAP

2' MIN

2' MIN

5' MIN

VENT PIPE

CAUTION: The heater and its manual

URE TO FOLLOW THIS PROCEDURE MAY DAM- AGE THE GAS VALVE. OVER PRESSURIZED GAS VALVES ARE NOT COVERED BY WARRANTY. The heater and its gas connections shall be leak tested before placing the appliance in operation. Use soapy water for leak test. DO NOT use open flame.

DRAFT HOOD ![]()

HEATER ![]()

NOTE: Do not use Teflon tape on gas line pipe thread. A flexible sealant suitable for LP gases is recommended.

A minimum of 7 in. WC and a maximum of 14 in. WC upstream pressure under load, and

Fig.# 8119.2 gas.

19