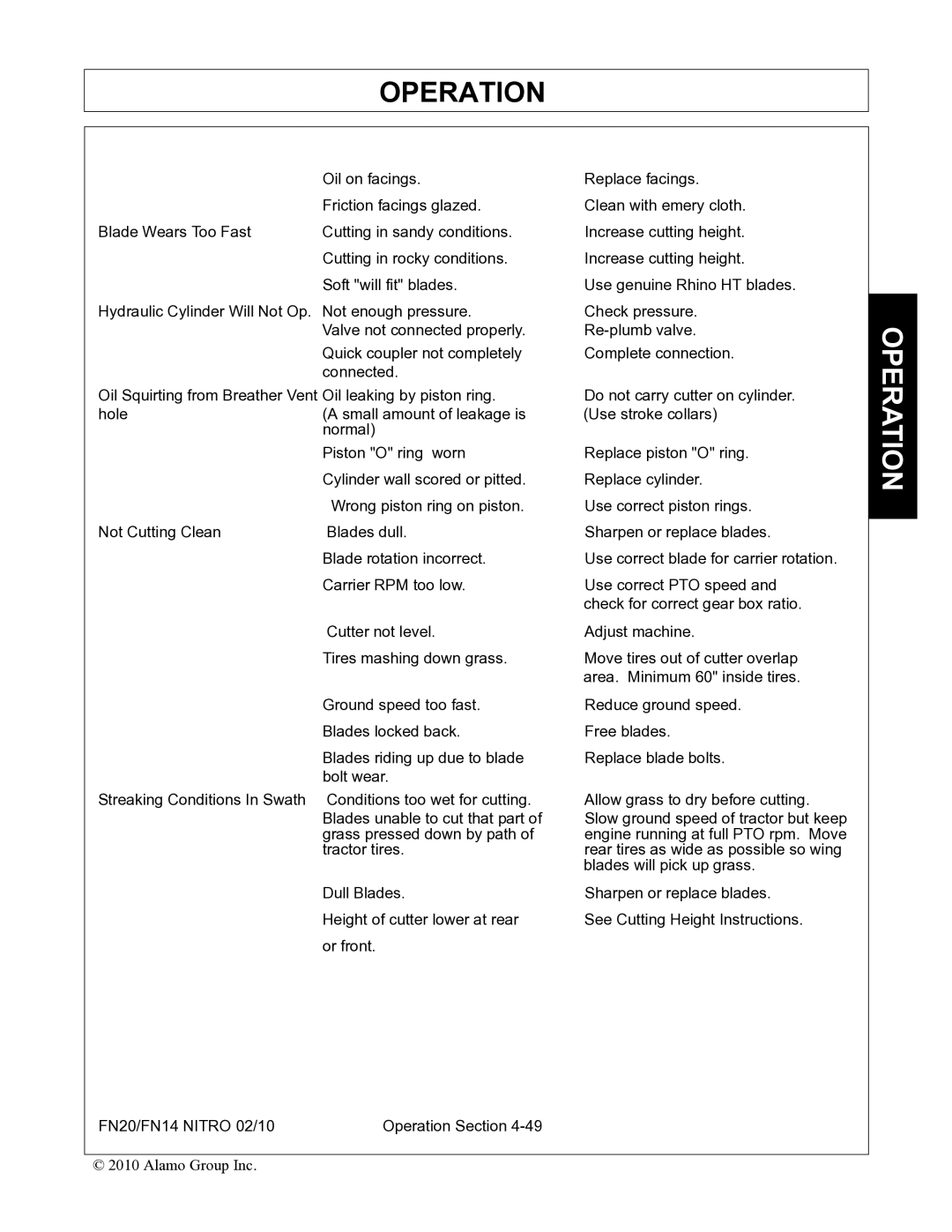

OPERATION

| Oil on facings. |

| Friction facings glazed. |

Blade Wears Too Fast | Cutting in sandy conditions. |

| Cutting in rocky conditions. |

Soft "will fit" blades.

Hydraulic Cylinder Will Not Op. Not enough pressure.

Valve not connected properly.

Quick coupler not completely connected.

Oil Squirting from Breather Vent Oil leaking by piston ring.

hole(A small amount of leakage is normal)

| Piston "O" ring worn |

| Cylinder wall scored or pitted. |

| Wrong piston ring on piston. |

Not Cutting Clean | Blades dull. |

| Blade rotation incorrect. |

| Carrier RPM too low. |

| Cutter not level. |

| Tires mashing down grass. |

| Ground speed too fast. |

| Blades locked back. |

| Blades riding up due to blade |

| bolt wear. |

Streaking Conditions In Swath | Conditions too wet for cutting. |

| Blades unable to cut that part of |

| grass pressed down by path of |

| tractor tires. |

| Dull Blades. |

| Height of cutter lower at rear |

| or front. |

Replace facings. Clean with emery cloth. Increase cutting height. Increase cutting height.

Use genuine Rhino HT blades.

Check pressure.

Complete connection.

Do not carry cutter on cylinder. (Use stroke collars)

Replace piston "O" ring. Replace cylinder.

Use correct piston rings. Sharpen or replace blades.

Use correct blade for carrier rotation.

Use correct PTO speed and check for correct gear box ratio.

Adjust machine.

Move tires out of cutter overlap area. Minimum 60" inside tires.

Reduce ground speed. Free blades.

Replace blade bolts.

Allow grass to dry before cutting. Slow ground speed of tractor but keep engine running at full PTO rpm. Move rear tires as wide as possible so wing blades will pick up grass.

Sharpen or replace blades. See Cutting Height Instructions.

OPERATION

FN20/FN14 NITRO 02/10 | Operation Section |

© 2010 Alamo Group Inc.