MAINTENANCE

INSPECTION

1.Discard the two crosses, all of the bearing cups, and all of the snap rings.

2.Clean the bores in the center housing and the yokes. Inspect the bores for damage. Replace any parts that are damaged.

3.Clean the snap ring grooves in the bores that have them. Inspect the snap ring grooves for damage. Replace any parts that are damaged.

4.Clean the trunnions of the center plate in the center housing. Make sure that none of the needles from the bearings have fallen into the center plate area of the center housing. Make sure center plate moves freely by hand.

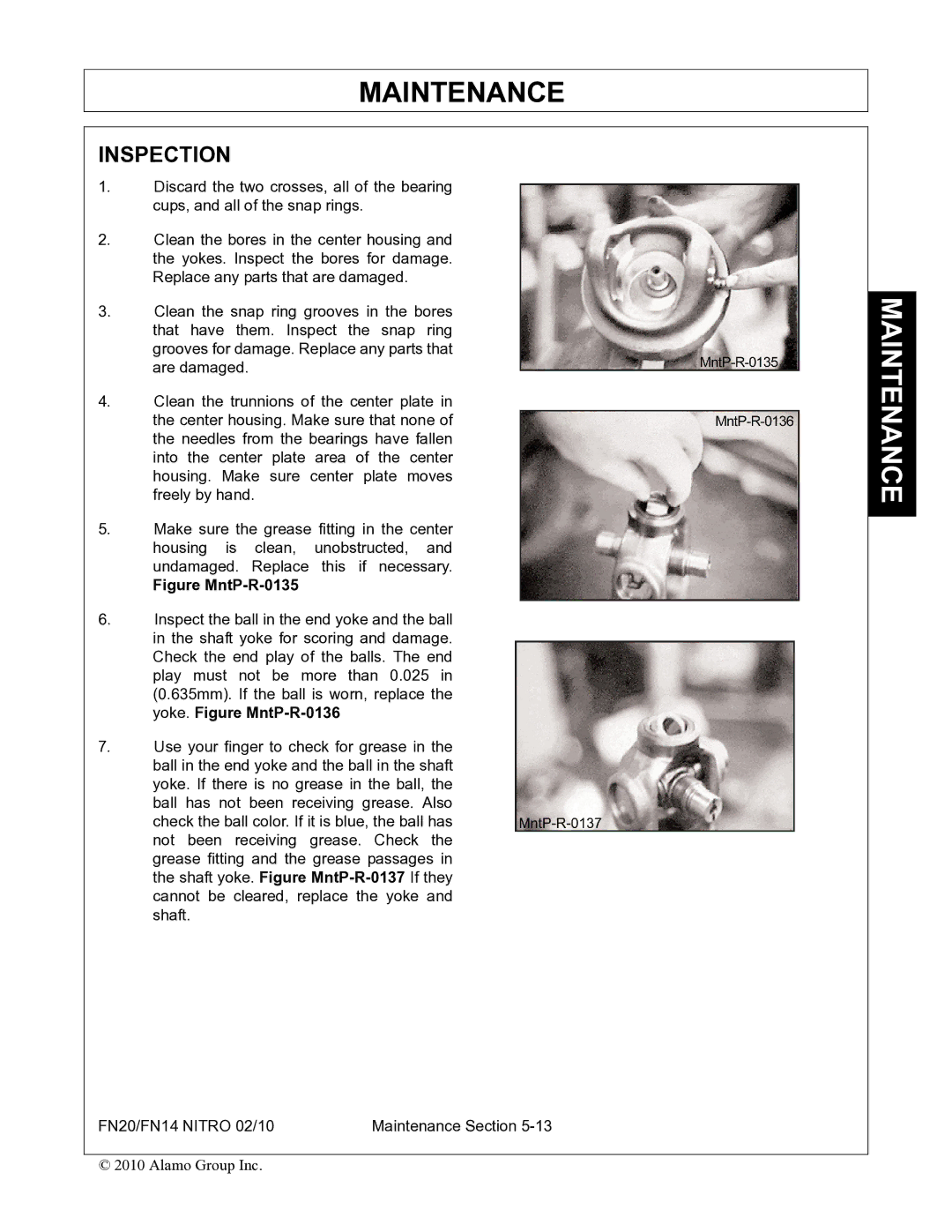

5.Make sure the grease fitting in the center housing is clean, unobstructed, and undamaged. Replace this if necessary.

Figure MntP-R-0135

6.Inspect the ball in the end yoke and the ball in the shaft yoke for scoring and damage. Check the end play of the balls. The end play must not be more than 0.025 in (0.635mm). If the ball is worn, replace the yoke. Figure

7.Use your finger to check for grease in the ball in the end yoke and the ball in the shaft yoke. If there is no grease in the ball, the ball has not been receiving grease. Also check the ball color. If it is blue, the ball has not been receiving grease. Check the grease fitting and the grease passages in the shaft yoke. Figure

FN20/FN14 NITRO 02/10 | Maintenance Section |

© 2010 Alamo Group Inc.