MAINTENANCE

DISASSEMBLY - CROSS AND BEARING KIT

1.The implement driveline has been removed from the machine, the two halves separated, and the guards removed. Start the procedure by removing the yoke that does not have a shaft attached.

2.The bearing cups are held in the center housing by snap rings. The snap rings are on either the inner edge of the bearing cup (internal), or on the cup end (external).

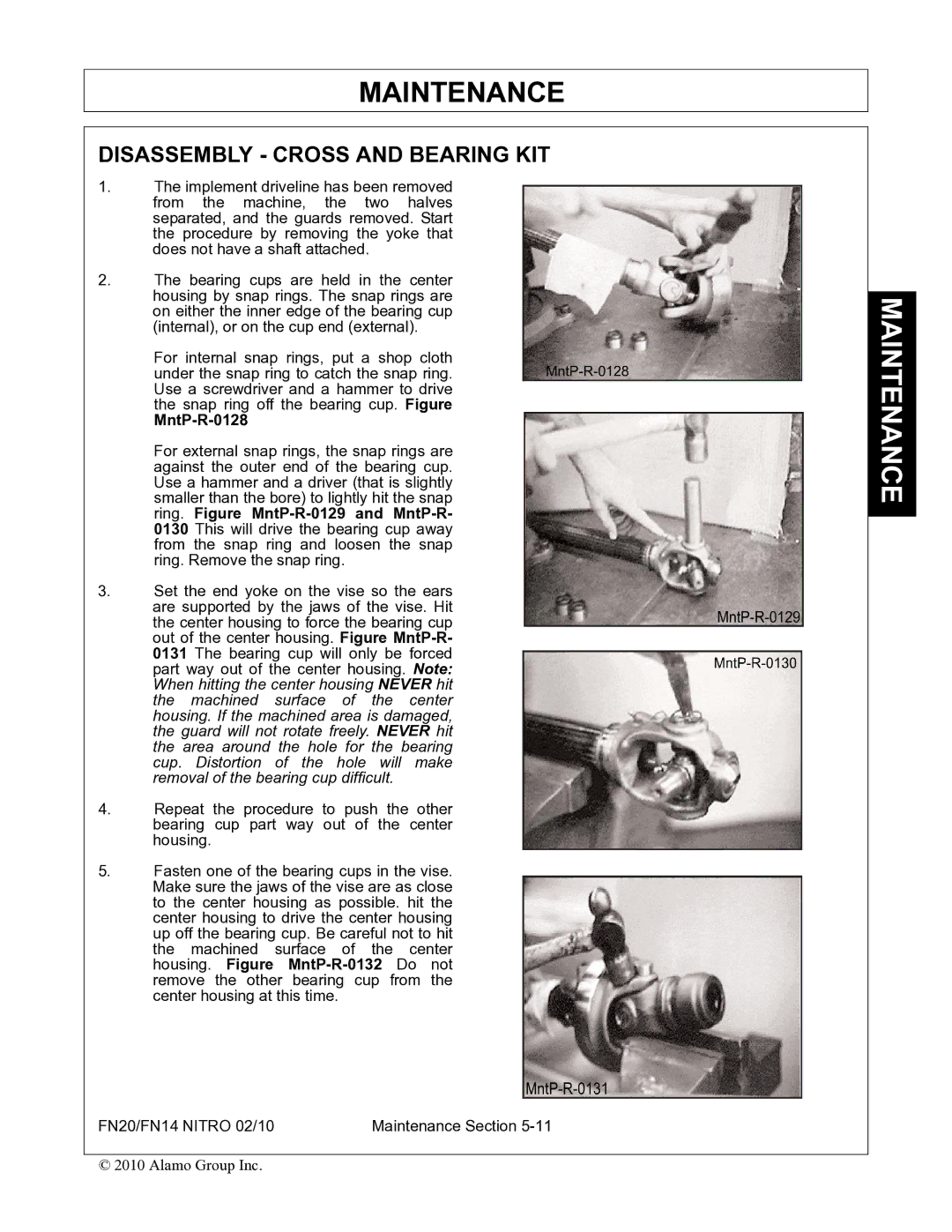

For internal snap rings, put a shop cloth under the snap ring to catch the snap ring. Use a screwdriver and a hammer to drive the snap ring off the bearing cup. Figure

MntP-R-0128

For external snap rings, the snap rings are against the outer end of the bearing cup. Use a hammer and a driver (that is slightly smaller than the bore) to lightly hit the snap ring. Figure

3.Set the end yoke on the vise so the ears are supported by the jaws of the vise. Hit the center housing to force the bearing cup out of the center housing. Figure

4.Repeat the procedure to push the other bearing cup part way out of the center housing.

5.Fasten one of the bearing cups in the vise. Make sure the jaws of the vise are as close to the center housing as possible. hit the center housing to drive the center housing up off the bearing cup. Be careful not to hit the machined surface of the center housing. Figure

FN20/FN14 NITRO 02/10 | Maintenance Section |

© 2010 Alamo Group Inc.