Unit 4: Operation

OPERATIONAL ADJUSTMENTS

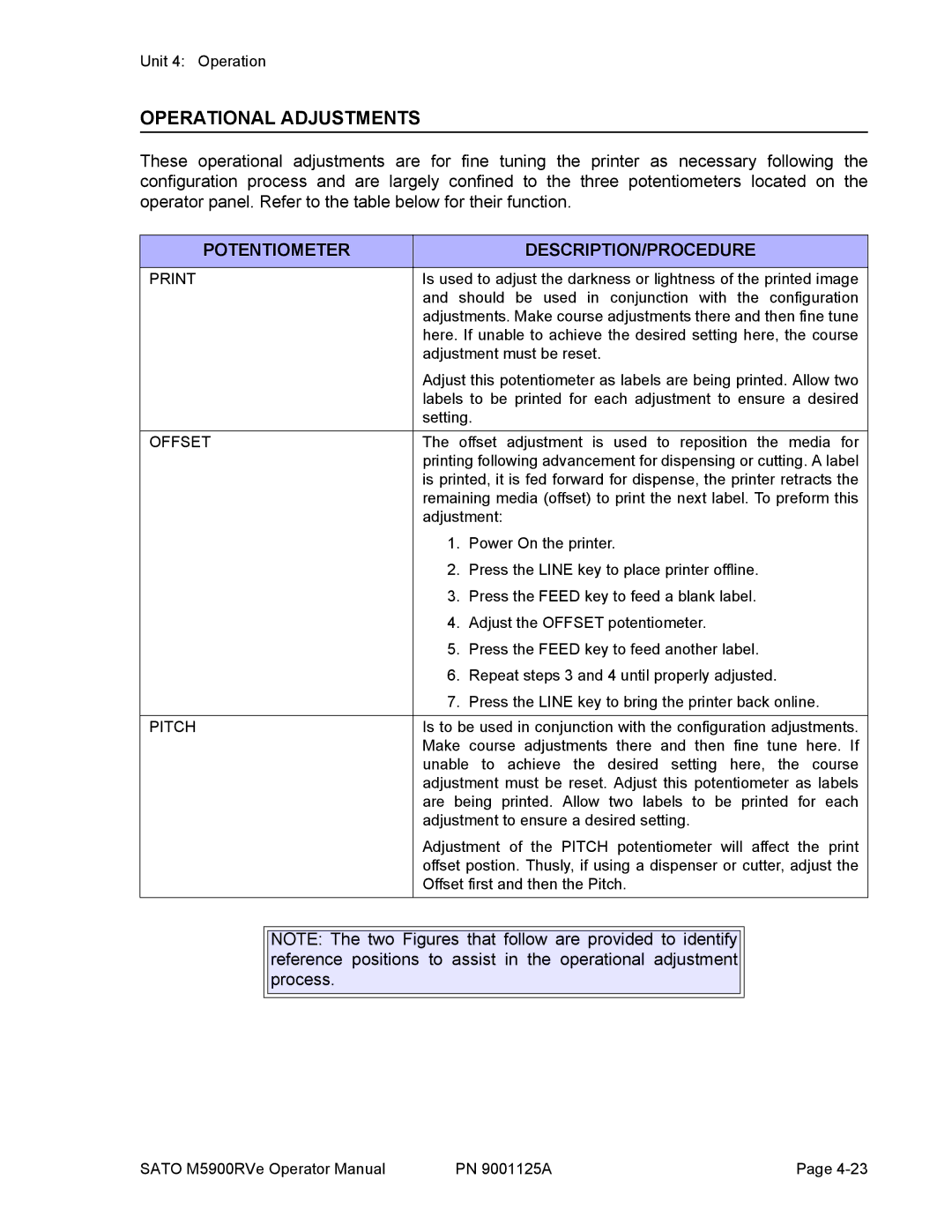

These operational adjustments are for fine tuning the printer as necessary following the configuration process and are largely confined to the three potentiometers located on the operator panel. Refer to the table below for their function.

POTENTIOMETER |

| DESCRIPTION/PROCEDURE |

|

| |

Is used to adjust the darkness or lightness of the printed image | ||

| and should be used in conjunction with the configuration | |

| adjustments. Make course adjustments there and then fine tune | |

| here. If unable to achieve the desired setting here, the course | |

| adjustment must be reset. | |

| Adjust this potentiometer as labels are being printed. Allow two | |

| labels to be printed for each adjustment to ensure a desired | |

| setting. | |

|

| |

OFFSET | The offset adjustment is used to reposition the media for | |

| printing following advancement for dispensing or cutting. A label | |

| is printed, it is fed forward for dispense, the printer retracts the | |

| remaining media (offset) to print the next label. To preform this | |

| adjustment: | |

| 1. | Power On the printer. |

| 2. | Press the LINE key to place printer offline. |

| 3. | Press the FEED key to feed a blank label. |

| 4. | Adjust the OFFSET potentiometer. |

| 5. | Press the FEED key to feed another label. |

| 6. | Repeat steps 3 and 4 until properly adjusted. |

| 7. | Press the LINE key to bring the printer back online. |

|

| |

PITCH | Is to be used in conjunction with the configuration adjustments. | |

| Make course adjustments there and then fine tune here. If | |

| unable to achieve the desired setting here, the course | |

| adjustment must be reset. Adjust this potentiometer as labels | |

| are being printed. Allow two labels to be printed for each | |

| adjustment to ensure a desired setting. | |

| Adjustment of the PITCH potentiometer will affect the print | |

| offset postion. Thusly, if using a dispenser or cutter, adjust the | |

| Offset first and then the Pitch. | |

|

|

|

NOTE: The two Figures that follow are provided to identify reference positions to assist in the operational adjustment process.

SATO M5900RVe Operator Manual | PN 9001125A | Page |