CME1356R and CME1656R

Refrigerant

1.This ice machine uses

A. It is a

B. It must use polyol ester refrigerant oil, and that oil is very water absorbent. The system must not be open for more than 15 minutes.

C. An electronic leak detector capable of locating

D. A special HFC type liquid line dryer must be used.

E. When brazing, a dry nitrogen purge is required.

F. When evacuating, use of an electronic micron gage is recommend. Evacuate to 300 microns.

Recovering the Refrigerant

Because of the check valves, liquid refrigerant must be recovered thru the liquid line valve, as well as the low side access valve at the front of the machine.

Access Valves:

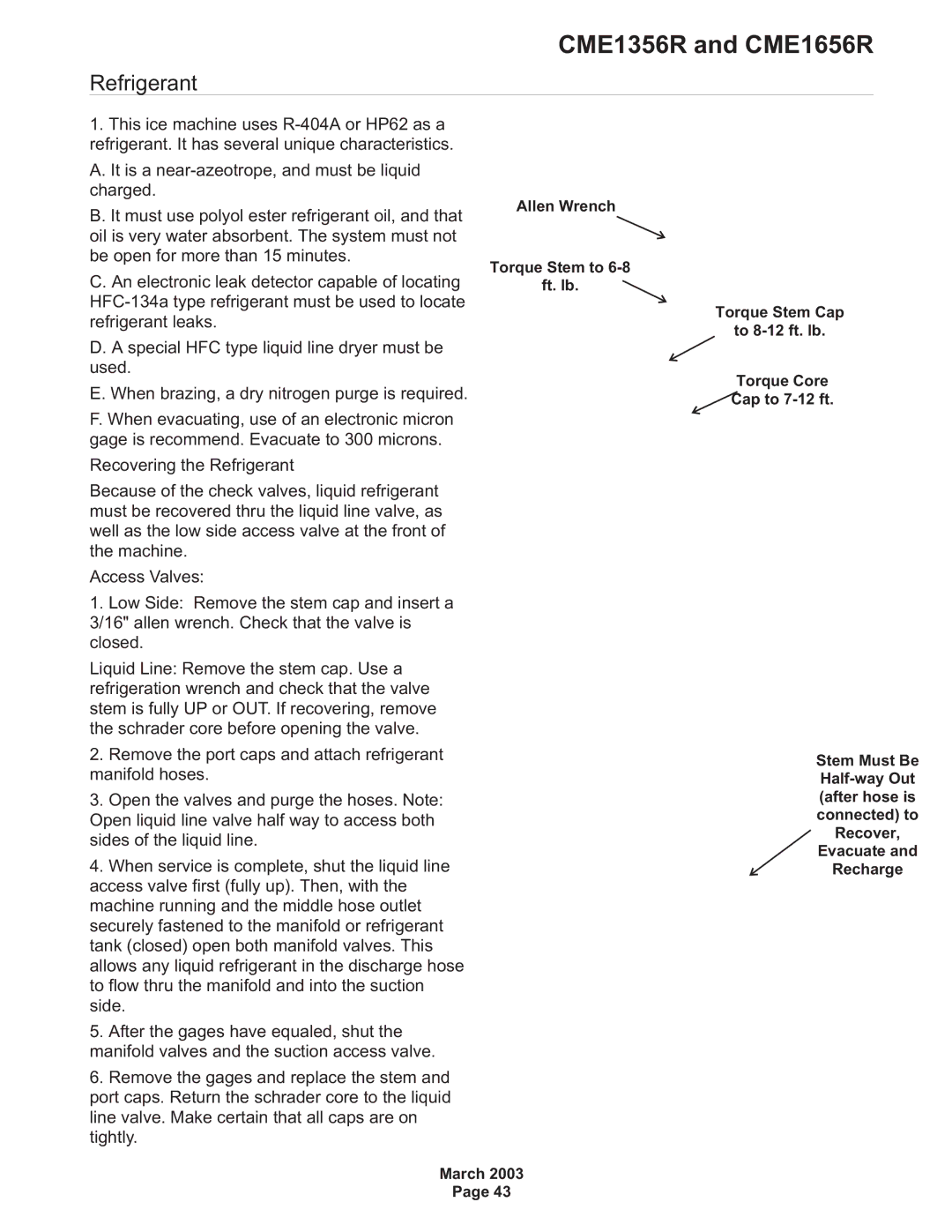

1.Low Side: Remove the stem cap and insert a 3/16" allen wrench. Check that the valve is closed.

Liquid Line: Remove the stem cap. Use a refrigeration wrench and check that the valve stem is fully UP or OUT. If recovering, remove the schrader core before opening the valve.

2.Remove the port caps and attach refrigerant manifold hoses.

3.Open the valves and purge the hoses. Note: Open liquid line valve half way to access both sides of the liquid line.

4.When service is complete, shut the liquid line access valve first (fully up). Then, with the machine running and the middle hose outlet securely fastened to the manifold or refrigerant tank (closed) open both manifold valves. This allows any liquid refrigerant in the discharge hose to flow thru the manifold and into the suction side.

5.After the gages have equaled, shut the manifold valves and the suction access valve.

6.Remove the gages and replace the stem and port caps. Return the schrader core to the liquid line valve. Make certain that all caps are on tightly.

Allen Wrench

Torque Stem to

ft. lb.

Torque Stem Cap

to

Torque Core

Cap to

Low Side Access Valve

Stem Must Be

Liquid Line Access Valve

March 2003

Page 43