EX500 Serial System | EX## - OME0008 |

4.How to operate EX500 - GAB1 - X1 ( Rockwell Automation Remote I/O ( RIO))

4

Applicable PLCs in which Rockwell Automation Remote I/O ( RIO ) system is installed. Please contact Rockwell Automation for more details.

・Representative PLC

SLC500 |

|

|

|

|

| |

PLC - 2 / 20 | PLC - 2 / 30 | PLC - 3 | / 10 |

| ||

PLC - 5 | / 11 | PLC - 5 | / 15 | PLC - 5 | / 20 | PLC - 5 / 25 |

PLC - 5 | / 30 | PLC - 5 | / 40 | PLC - 5 | / 40L | PLC - 5 / 60 |

PLC - 5 | / 60L | PLC - 5 | / 80 |

|

|

|

PLC - 5 | / 250 | PLC - 5 | / VME | PLC - 5 | / V40B |

|

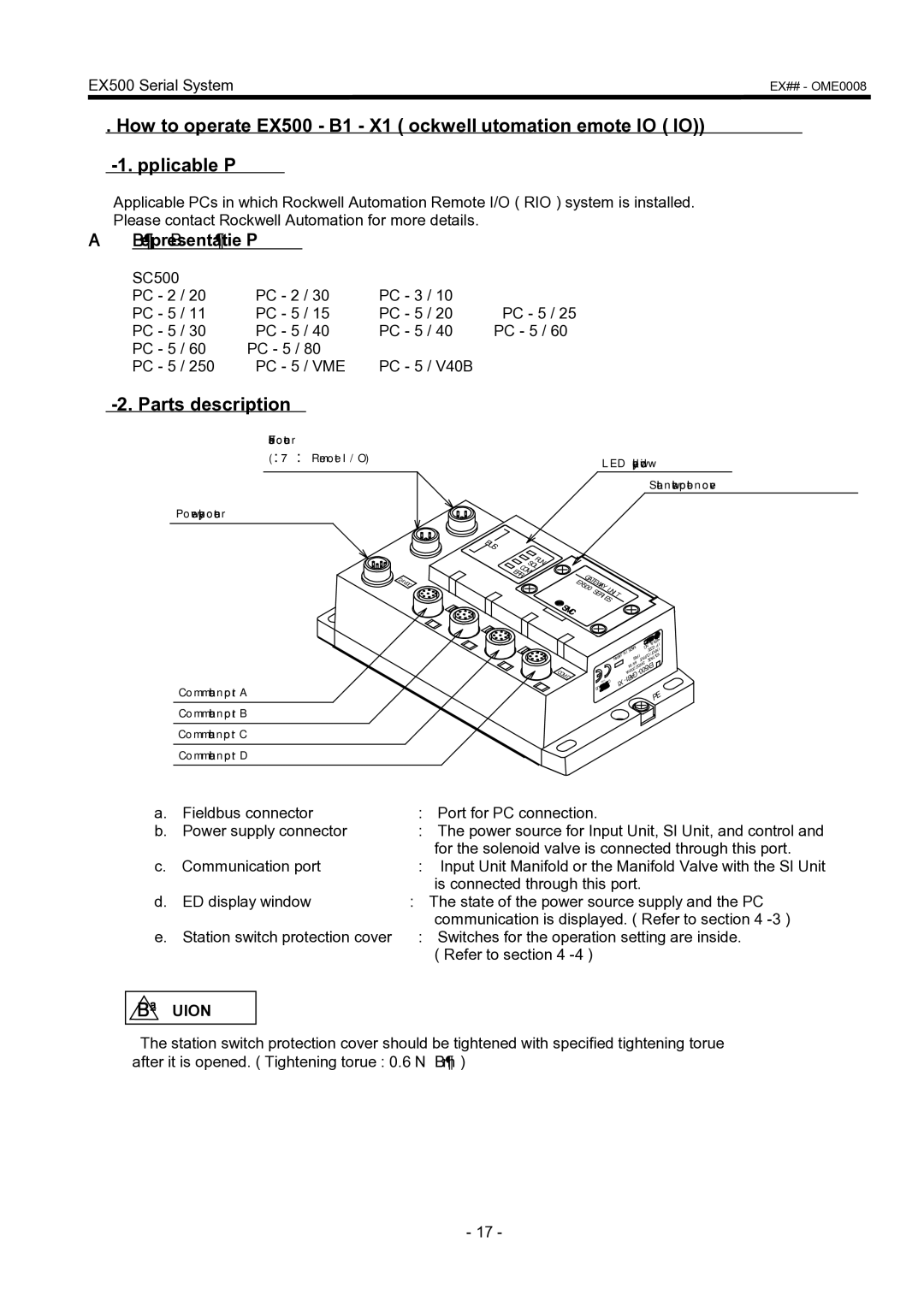

4 -2. Parts description

Fieldbus connector (1771 Remote I/O)

Power supply connector

24VDC

Communication port A

Communication port B

Communication port C

Communication port D

LED display window

Station switch protection cover

BUS

|

|

|

|

| R |

|

|

|

|

|

|

|

| |

|

|

|

| S |

| U |

|

|

|

|

|

|

|

|

|

|

|

|

| N |

|

|

|

|

|

|

|

| |

| C |

| O |

|

|

|

|

|

|

|

|

|

| |

|

|

| L |

|

|

|

|

|

|

|

|

| ||

E |

| O |

|

|

|

|

|

|

|

|

|

|

| |

|

| M |

|

|

|

|

|

|

|

|

|

| ||

RR |

|

|

|

|

| GA |

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

| EX |

| T |

|

|

|

|

| |

|

|

|

|

|

|

|

| EW |

|

|

| |||

|

|

|

|

|

| 50 |

|

|

| AY | U |

| ||

|

|

|

|

|

|

| 0 | S |

|

|

| |||

|

|

|

|

|

|

|

|

|

|

| N | |||

|

|

|

|

|

|

|

|

|

| ER |

|

| IT | |

|

|

|

|

|

|

|

|

|

|

| I |

|

| |

|

|

|

|

|

|

|

|

|

|

|

| ES |

| |

S |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

M |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

| C |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ES | |

|

|

|

|

|

|

|

|

|

|

|

|

|

| IR | I | |

|

|

|

|

|

|

|

|

|

|

| N | LA |

| |||

|

|

|

|

|

|

| D | AM |

| .O |

| OC | NI | |||

|

|

|

|

|

|

|

|

|

|

| ED |

| ||||

|

|

|

|

|

| N | IE |

|

|

|

|

|

| UP | V | |

|

|

|

|

| AJ |

|

|

| I |

| UO |

|

| LO | ||

|

|

|

| AP |

|

| P | PT |

| AT |

|

| ||||

|

|

|

| N |

|

|

| 56 | TU |

| EG |

|

|

| ||

|

|

|

|

|

|

| /46 |

| 42 |

|

|

|

|

|

| |

|

|

|

|

|

|

| 46 | 2/ |

|

| 5X |

|

|

| ||

|

|

|

|

|

|

|

| CDV | 0 |

|

| E |

|

| ||

C |

|

|

|

|

|

| 00 |

|

|

|

|

|

|

| ||

|

|

|

|

|

| Am |

| 0 |

|

|

|

|

|

| ||

OM | D |

|

|

|

|

|

| G- |

|

|

|

|

|

|

| |

| PY T | C |

| X- | BA |

|

|

|

|

|

|

|

| |||

| 1E |

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

| 1 |

| 1 |

|

|

|

|

|

|

|

|

| |

| SU |

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| E | |

|

|

|

|

|

|

|

|

|

|

|

|

|

| P |

| |

a. | Fieldbus connector | : Port for PLC connection. |

b. | Power supply connector | : The power source for Input Unit, SI Unit, and control and |

|

| for the solenoid valve is connected through this port. |

c. | Communication port | : Input Unit Manifold or the Manifold Valve with the SI Unit |

|

| is connected through this port. |

d. | LED display window | : The state of the power source supply and the PLC |

|

| communication is displayed. ( Refer to section 4 |

e. | Station switch protection cover | : Switches for the operation setting are inside. |

|

| ( Refer to section 4 |

!CAUTION

The station switch protection cover should be tightened with specified tightening torque after it is opened. ( Tightening torque : 0.6 N・m )

- 17 -