For Machines Mfg. Since 8/11 | O P E R A T I O N | Model SB1001 8K™ Lathe |

Chuck Removal

To remove the chuck:

1.DISCONNECT LATHE FROM POWER!

2.Place a sturdy piece of plywood under the spindle to protect the bed ways during the removal process.

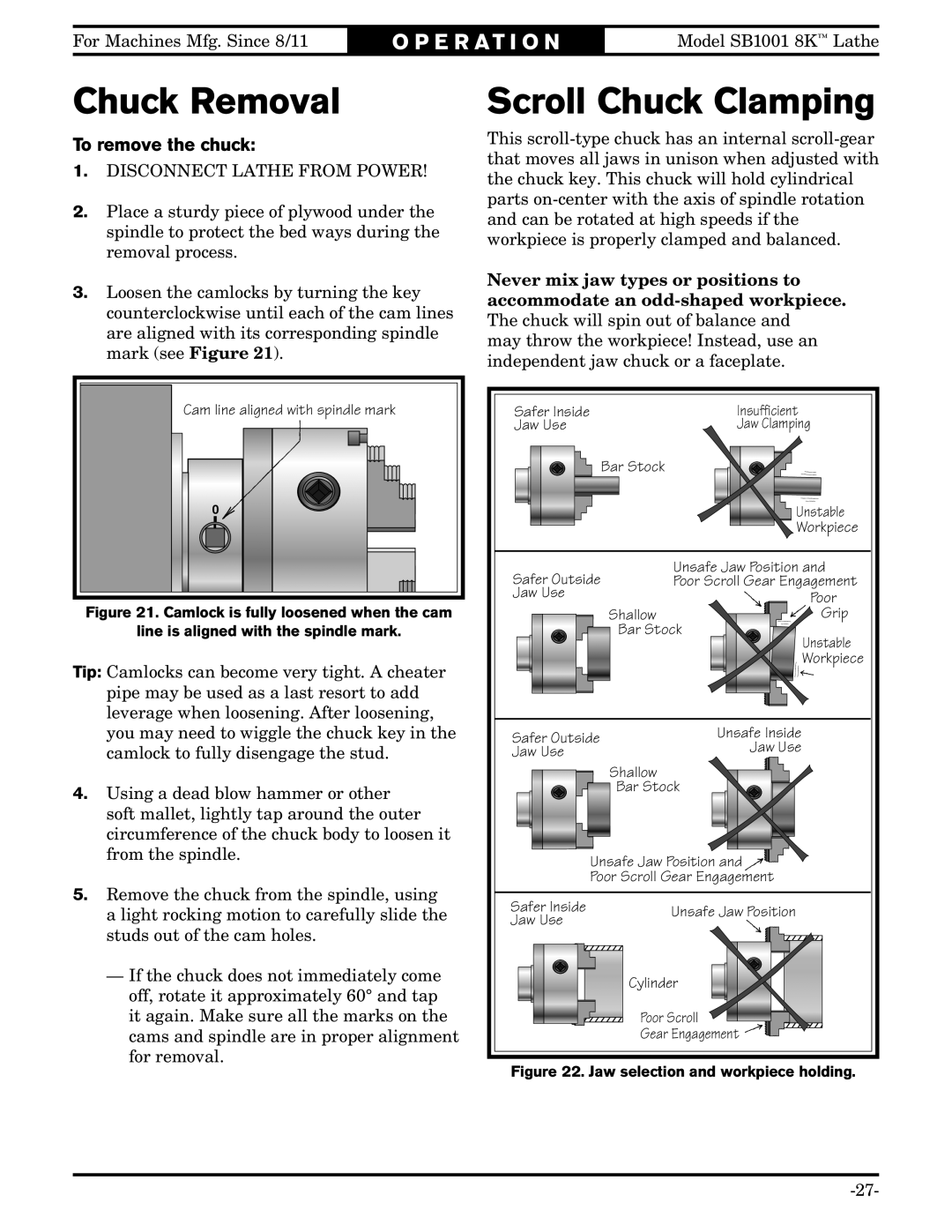

3.Loosen the camlocks by turning the key counterclockwise until each of the cam lines are aligned with its corresponding spindle mark (see Figure 21).

Cam line aligned with spindle mark |

0 |

Figure 21. Camlock is fully loosened when the cam

line is aligned with the spindle mark.

Tip: Camlocks can become very tight. A cheater pipe may be used as a last resort to add leverage when loosening. After loosening, you may need to wiggle the chuck key in the camlock to fully disengage the stud.

4.Using a dead blow hammer or other soft mallet, lightly tap around the outer circumference of the chuck body to loosen it from the spindle.

5.Remove the chuck from the spindle, using a light rocking motion to carefully slide the studs out of the cam holes.

—If the chuck does not immediately come off, rotate it approximately 60° and tap it again. Make sure all the marks on the cams and spindle are in proper alignment for removal.

Scroll Chuck Clamping

This

Never mix jaw types or positions to accommodate an

may throw the workpiece! Instead, use an independent jaw chuck or a faceplate.

Safer Inside | Insufficient | |

Jaw Use | Jaw Clamping | |

Bar Stock |

| |

| Unstable | |

| Workpiece | |

Safer Outside | Unsafe Jaw Position and | |

Poor Scroll Gear Engagement | ||

Jaw Use | Poor | |

Shallow | Grip | |

Bar Stock | ||

| Unstable | |

| Workpiece | |

Safer Outside | Unsafe Inside | |

Jaw Use | ||

Jaw Use | ||

Shallow |

| |

Bar Stock | ||

Unsafe Jaw Position and | ||

Poor Scroll Gear Engagement | ||

Safer Inside | Unsafe Jaw Position | |

Jaw Use | ||

| ||

Cylinder | ||

Poor Scroll | ||

Gear Engagement | ||