Model SB1001 8K™ Lathe | P R E P A R A T I O N | For Machines Mfg. Since 8/11 |

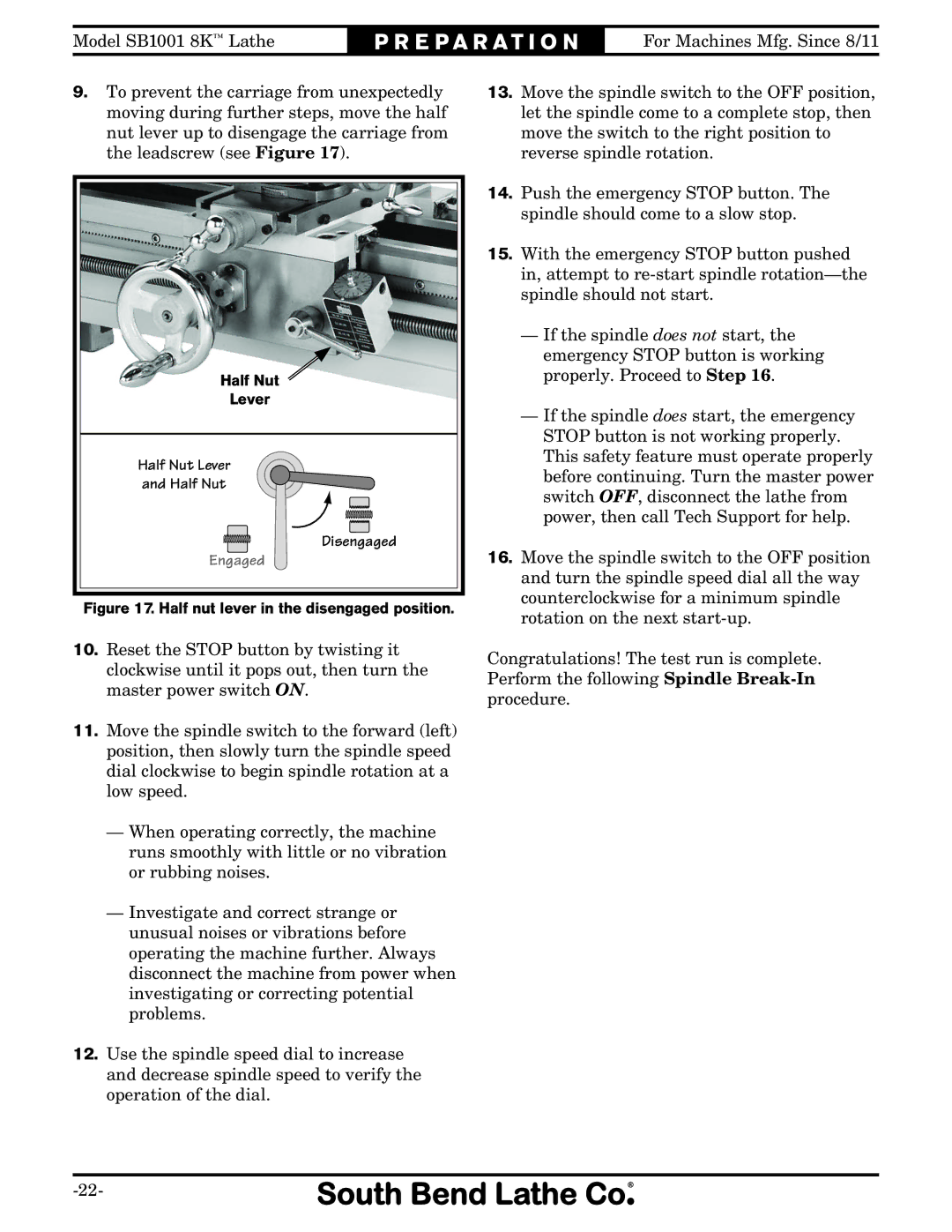

9.To prevent the carriage from unexpectedly moving during further steps, move the half nut lever up to disengage the carriage from the leadscrew (see Figure 17).

Half Nut

Lever

Half Nut Lever

and Half Nut

Disengaged

Engaged

Figure 17. Half nut lever in the disengaged position.

10.Reset the STOP button by twisting it clockwise until it pops out, then turn the master power switch ON.

11.Move the spindle switch to the forward (left) position, then slowly turn the spindle speed dial clockwise to begin spindle rotation at a low speed.

—When operating correctly, the machine runs smoothly with little or no vibration or rubbing noises.

—Investigate and correct strange or unusual noises or vibrations before operating the machine further. Always disconnect the machine from power when investigating or correcting potential problems.

12.Use the spindle speed dial to increase and decrease spindle speed to verify the operation of the dial.

13.Move the spindle switch to the OFF position, let the spindle come to a complete stop, then move the switch to the right position to reverse spindle rotation.

14.Push the emergency STOP button. The spindle should come to a slow stop.

15.With the emergency STOP button pushed in, attempt to

—If the spindle does not start, the emergency STOP button is working properly. Proceed to Step 16.

—If the spindle does start, the emergency STOP button is not working properly. This safety feature must operate properly before continuing. Turn the master power switch OFF, disconnect the lathe from power, then call Tech Support for help.

16.Move the spindle switch to the OFF position and turn the spindle speed dial all the way counterclockwise for a minimum spindle rotation on the next

Congratulations! The test run is complete. Perform the following Spindle