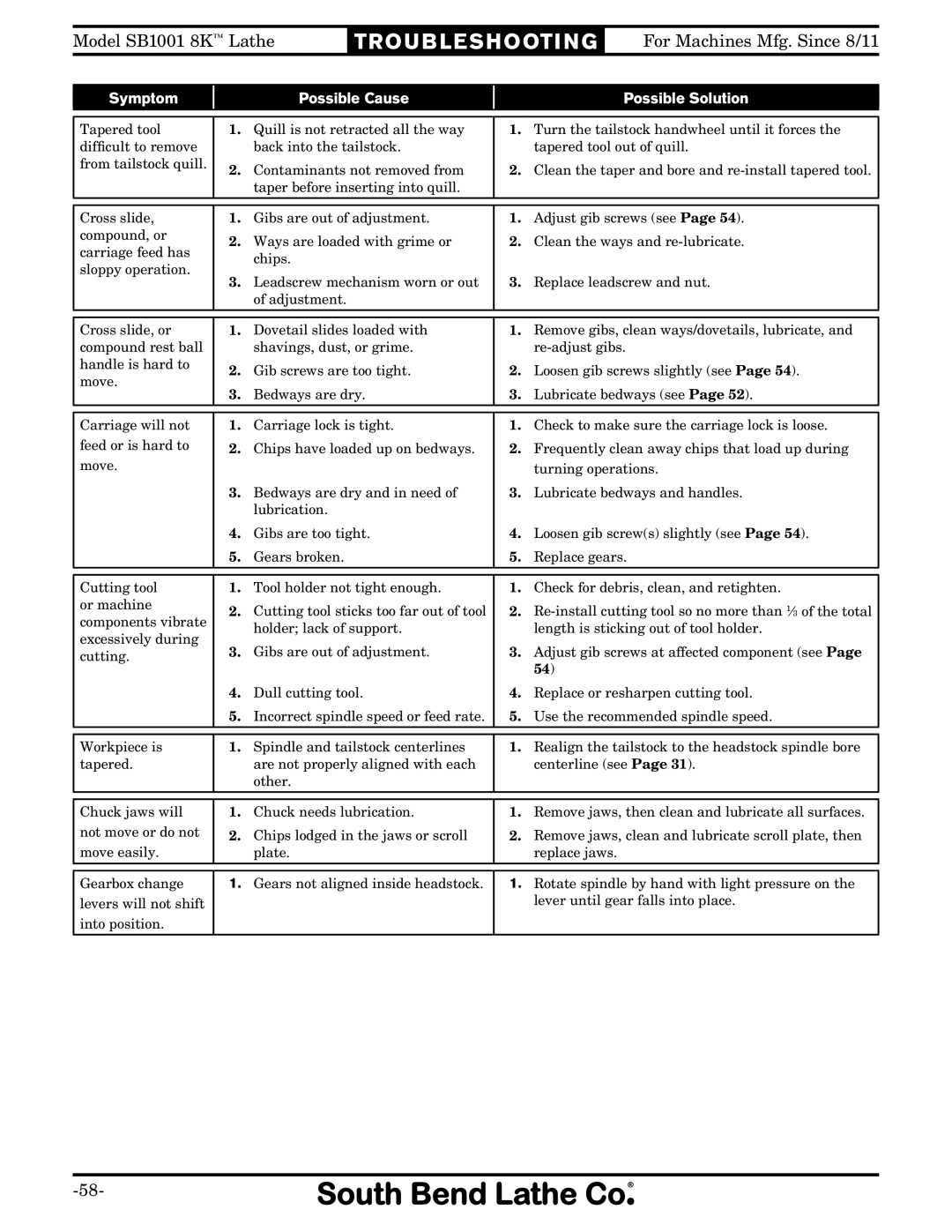

Model SB1001 8K™ Lathe | TROU B LESHOOTI NG | For Machines Mfg. Since 8/11 |

Symptom

Possible Cause

Possible Solution

Tapered tool | 1. | Quill is not retracted all the way | 1. | Turn the tailstock handwheel until it forces the | |

difficult to remove |

| back into the tailstock. |

| tapered tool out of quill. | |

from tailstock quill. | 2. | Contaminants not removed from | 2. | Clean the taper and bore and | |

| |||||

|

| taper before inserting into quill. |

|

| |

|

|

|

|

| |

|

|

|

|

| |

Cross slide, | 1. | Gibs are out of adjustment. | 1. | Adjust gib screws (see Page 54). | |

compound, or | 2. | Ways are loaded with grime or | 2. | Clean the ways and | |

carriage feed has | |||||

| chips. |

|

| ||

sloppy operation. |

|

|

| ||

3. | Leadscrew mechanism worn or out | 3. | Replace leadscrew and nut. | ||

| |||||

|

| of adjustment. |

|

| |

|

|

|

|

| |

|

|

|

|

| |

Cross slide, or | 1. | Dovetail slides loaded with | 1. | Remove gibs, clean ways/dovetails, lubricate, and | |

compound rest ball |

| shavings, dust, or grime. |

| ||

handle is hard to | 2. | Gib screws are too tight. | 2. | Loosen gib screws slightly (see Page 54). | |

move. | |||||

3. | Bedways are dry. | 3. | Lubricate bedways (see Page 52). | ||

| |||||

|

|

|

|

| |

|

|

|

|

| |

Carriage will not | 1. | Carriage lock is tight. | 1. | Check to make sure the carriage lock is loose. | |

feed or is hard to | 2. | Chips have loaded up on bedways. | 2. | Frequently clean away chips that load up during | |

move. |

|

|

| turning operations. | |

| 3. | Bedways are dry and in need of | 3. | Lubricate bedways and handles. | |

|

| lubrication. |

|

| |

| 4. | Gibs are too tight. | 4. | Loosen gib screw(s) slightly (see Page 54). | |

| 5. | Gears broken. | 5. | Replace gears. | |

|

|

|

|

| |

|

|

|

|

| |

Cutting tool | 1. | Tool holder not tight enough. | 1. | Check for debris, clean, and retighten. | |

or machine | 2. | Cutting tool sticks too far out of tool | 2. | ||

components vibrate |

| holder; lack of support. |

| length is sticking out of tool holder. | |

excessively during |

|

| |||

3. | Gibs are out of adjustment. | 3. | Adjust gib screws at affected component (see Page | ||

cutting. | |||||

|

|

|

| 54) | |

| 4. | Dull cutting tool. | 4. | Replace or resharpen cutting tool. | |

| 5. | Incorrect spindle speed or feed rate. | 5. | Use the recommended spindle speed. | |

|

|

|

|

| |

|

|

|

|

| |

Workpiece is | 1. | Spindle and tailstock centerlines | 1. | Realign the tailstock to the headstock spindle bore | |

tapered. |

| are not properly aligned with each |

| centerline (see Page 31). | |

|

| other. |

|

| |

|

|

|

|

| |

|

|

|

|

| |

Chuck jaws will | 1. | Chuck needs lubrication. | 1. | Remove jaws, then clean and lubricate all surfaces. | |

not move or do not | 2. | Chips lodged in the jaws or scroll | 2. | Remove jaws, clean and lubricate scroll plate, then | |

move easily. |

| plate. |

| replace jaws. | |

|

|

|

|

| |

Gearbox change | 1. | Gears not aligned inside headstock. | 1. | Rotate spindle by hand with light pressure on the | |

levers will not shift |

|

|

| lever until gear falls into place. | |

into position. |

|

|

|

|