Model SB1001 8K™ Lathe | O P E R A T I O N | For Machines Mfg. Since 8/11 |

Compound Rest

The compound rest ball handle has an indirect- read graduated scale. This means that the distance shown on the scale represents the actual distance the cutting tool moves. The base of the compound rest has another graduated scale used for setting the cutting tool to a specific angle.

Graduated Dial |

|

Increments | 0.001" |

One Full Revolution | 0.050" |

Tool Needed for Adjusting Angle | Qty |

Wrench 14mm | 1 |

To set the compound rest at a certain angle:

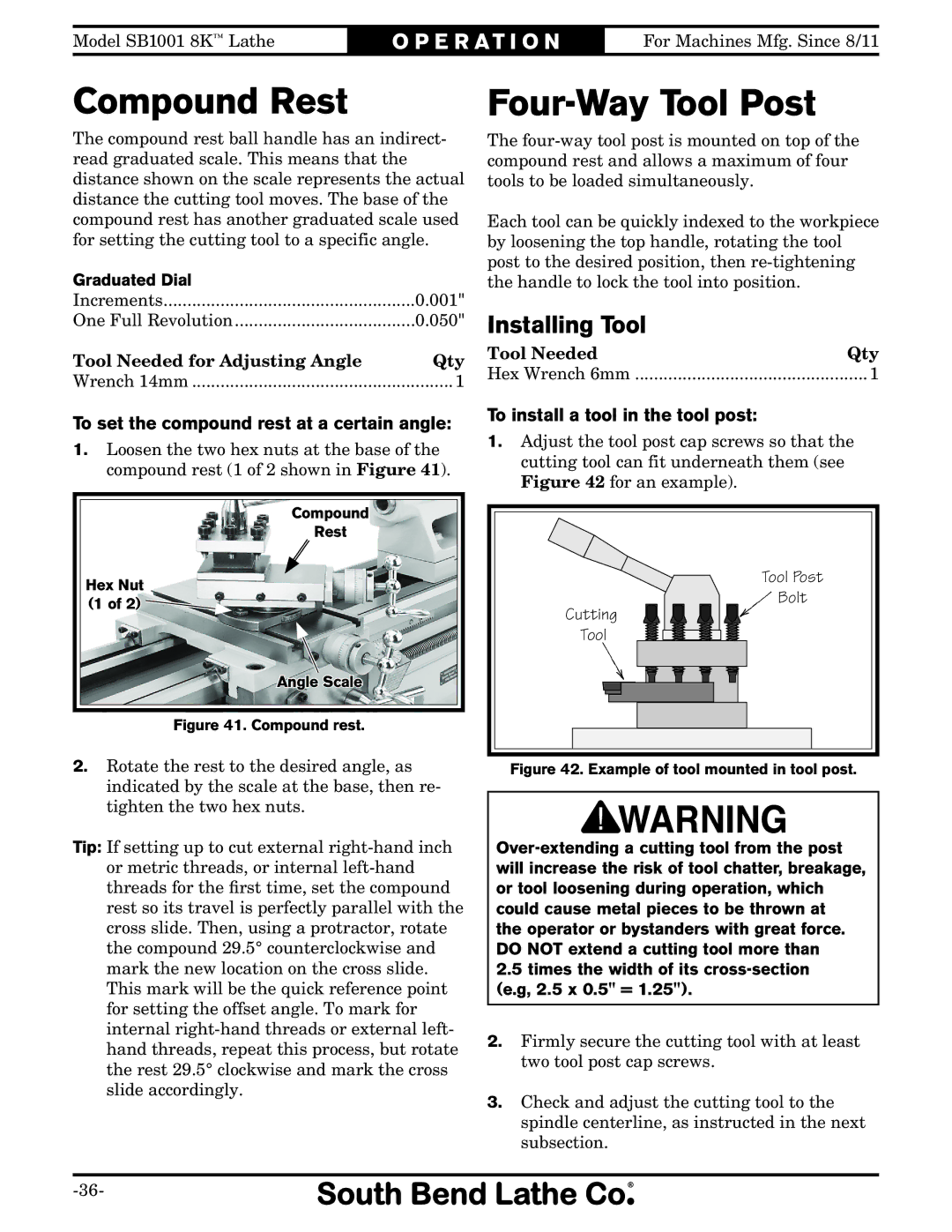

1.Loosen the two hex nuts at the base of the compound rest (1 of 2 shown in Figure 41).

Compound

Rest

Hex Nut

(1 of 2) ![]()

Angle Scale

Figure 41. Compound rest.

2.Rotate the rest to the desired angle, as indicated by the scale at the base, then re- tighten the two hex nuts.

Tip: If setting up to cut external

Four-Way Tool Post

The

Each tool can be quickly indexed to the workpiece by loosening the top handle, rotating the tool post to the desired position, then

Installing Tool |

|

Tool Needed | Qty |

Hex Wrench 6mm | 1 |

To install a tool in the tool post:

1.Adjust the tool post cap screws so that the cutting tool can fit underneath them (see Figure 42 for an example).

Tool Post

Bolt

Cutting

Tool

Figure 42. Example of tool mounted in tool post.

Over-extending a cutting tool from the post will increase the risk of tool chatter, breakage, or tool loosening during operation, which could cause metal pieces to be thrown at the operator or bystanders with great force. DO NOT extend a cutting tool more than

2.5times the width of its cross-section (e.g, 2.5 x 0.5" = 1.25").

2.Firmly secure the cutting tool with at least two tool post cap screws.

3.Check and adjust the cutting tool to the spindle centerline, as instructed in the next subsection.