Variable Speed Lathe

Scope of Manual

Updates

Customer Service

Manual Feedback

Table of Contents

Adjusting Drive Belts

About This Machine

Foreword

8K Lathe

Identification

Master Power Switch

Basic Controls Components

Control Panel

Carriage Tailstock

Carriage components

#$ %

704040%2 140 +70

Basic Machine Safety

Understanding Risks of Machinery

F E T Y

Additional Metal Lathe Safety

Additional Chuck Safety

Preparation Overview

Required for Setup

For Cleaning & Assembly

Typical preparation process is as follows

Full-Load Current Rating

Power Supply Requirements

Availability

Circuit Requirements

Grounding Requirements

Extension Cords

Unpacking

Inventory

Cleaning & Protecting

Before cleaning, gather the following

Basic steps for removing rust preventative

Location

Mounting

Leveling & Mounting

Leveling

Machine Base Work bench

Disconnecting Power

Power Connection

Connecting Power

Lubricating Lathe

Test Run

To test run your machine

Engaged

Spindle Break-In

Recommended Adjustments

Factory adjustments that should be verified

To perform the spindle break-in

Operation Overview

Chuck Installation

To install the chuck

Correct

Chuck Removal

Scroll Chuck Clamping

To remove the chuck

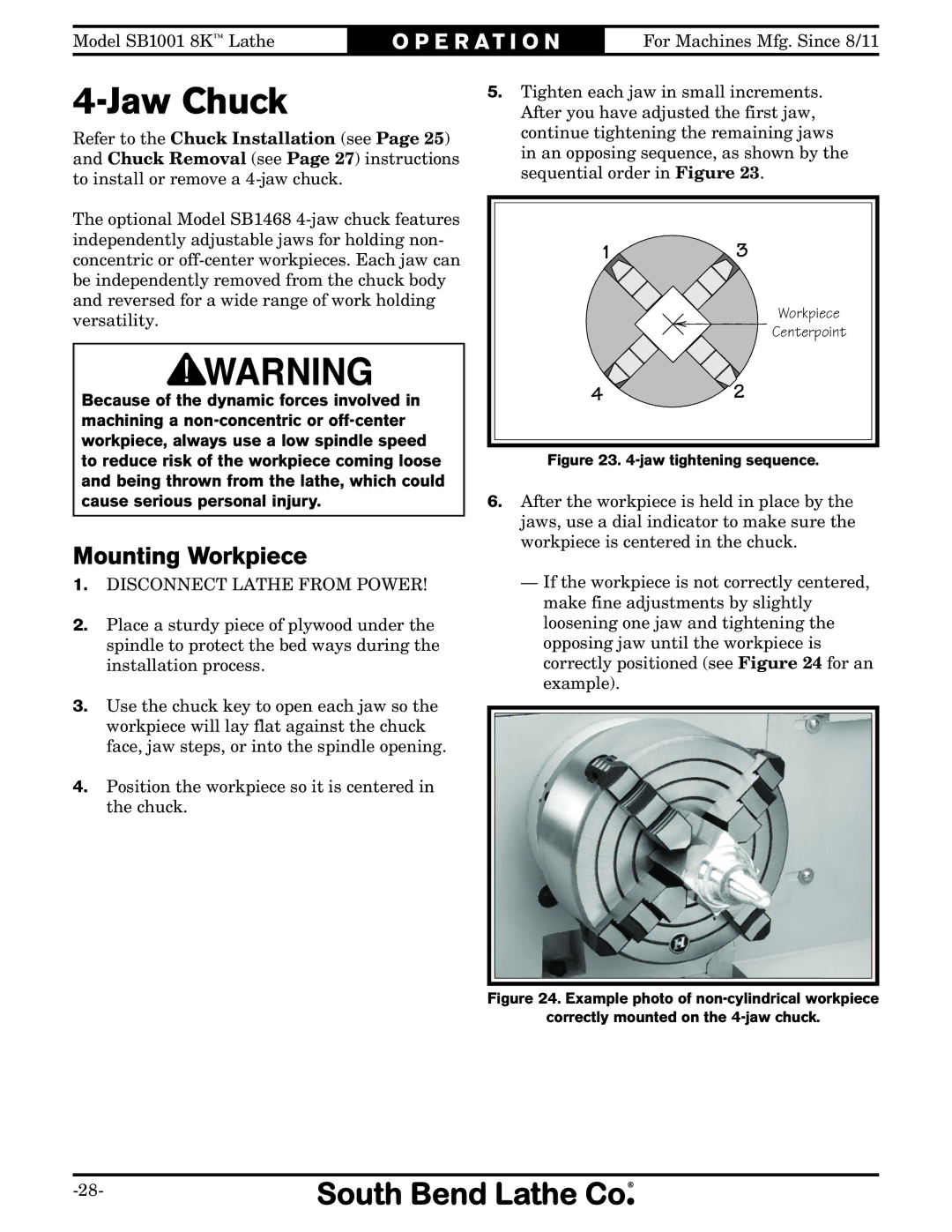

Jaw Chuck

Mounting Workpiece

Faceplate

To mount a non-concentric workpiece to the faceplate

To install tooling in the tailstock

Using Quill

Installing Tooling

Tailstock

To offset the tailstock

Offsetting Tailstock

Aligning Tailstock to Spindle Centerline

To align the tailstock to the spindle centerline

Looking down from above Move tailstock toward

Centers

Dead Centers

Live Centers

Removing Center from Spindle

Mounting Center in Spindle

Mounting Center in Tailstock

To mount a center in the tailstock

Carriage & Slide Locks

Mounting Workpiece Between Centers

Compound Rest

Installing Tool

To install a tool in the tool post

Four-Way Tool Post

Center

Aligning Cutting Tool with Spindle Centerline

To align the cutting tool with the tailstock

Top View

Manual Feed

Spindle Speed

Selecting Spindle Speed Range

To Change the Drive Belt Position

Tools Needed Qty

Timing Belts & Pulleys

Power Feed Threading Setup

Selecting Spindle Speed

Pulley Deflection

Setting Power Feed Rate

Setting Power Feed Rate of 0.0041/rev

Setting Threading Controls

Setting Thread Pitch of 12 TPI

16 B

Thread Dial

10, 14, or 18 TPI

Thread Dial Chart

12, 20, or 28 TPI

16, 24, or 32 TPI

Changing Feed Direction

To change the position of the feed direction gears

Accessories

SB1281-MT#2 High-Performance Live Center Set

SB1470-Steady Rest for SB1001 SB1471-Follow Rest for SB1001

SB1245-MT#2 Bull Nose Center

SB1391-D1-3 Back Plate

SB1354-South Bend Cast-Iron Workbench Legs, 1 Pair

Ongoing

Maintenance Schedule

Daily, After Operations

Daily, Before Operations

Lubrication

Spindle Bearings

Oil Gun

Feed Direction Gears

To lubricate the feed direction gears

Grease Fittings

Longitudinal Leadscrew

Jaw Chuck

Bedways & Slides

To prepare the lathe for storage

Leadscrew End Play Adjustment

Machine Storage

To remove leadscrew end play

Gib Adjustment

To adjust the saddle gib

Saddle Gib

Adjusting Drive Belts

To adjust the drive belts

Cross Slide & Compound Rest Gibs

Pulley Deflection

Trou B Leshooti NG

Trou B Leshooti NG

Electrical Safety Instructions

Wiring Diagram Color KEY

Electrical Cabinet Wiring Diagram

A12-30-10 To ON/OFF

Headstock

Description

Bed & Timing-Belt

Bed & Timing-Belt Pulleys Parts List

Saddle & Cross Slide

Compound Rest & Tool Post

Tool Post Lever

Apron

Quill

Electrical & End Cover

723 701 728

Labels

Door Closed Label

Page

Page

Warranty

#TS14279