For Machines Mfg. Since 8/11 | O P E R A T I O N | Model SB1001 8K™ Lathe |

Offsetting Tailstock

The tailstock can be offset from the spindle centerline for turning tapers. Move the tailstock top casting toward the front of the lathe to machine a taper at the tailstock end. Conversely, position the tailstock top casting toward the back of the lathe to machine a taper at the spindle end.

Note: The marks on the offset indicator are |

|

arbitrary. For a precise offset, use a dial |

|

indicator to check quill movement while |

|

adjusting the screws. |

|

Tools Needed | Qty |

Hex Wrench 3mm | 1 |

Wrench 13mm | 1 |

To offset the tailstock:

1.Loosen the tailstock lock nut to release the clamping pressure between the top and bottom castings (see Figure 28).

Tailstock

Lock Nut

Offset Set Screw

(1 of 2)

Offset

![]() Scale

Scale

Figure 28. Tailstock offset controls.

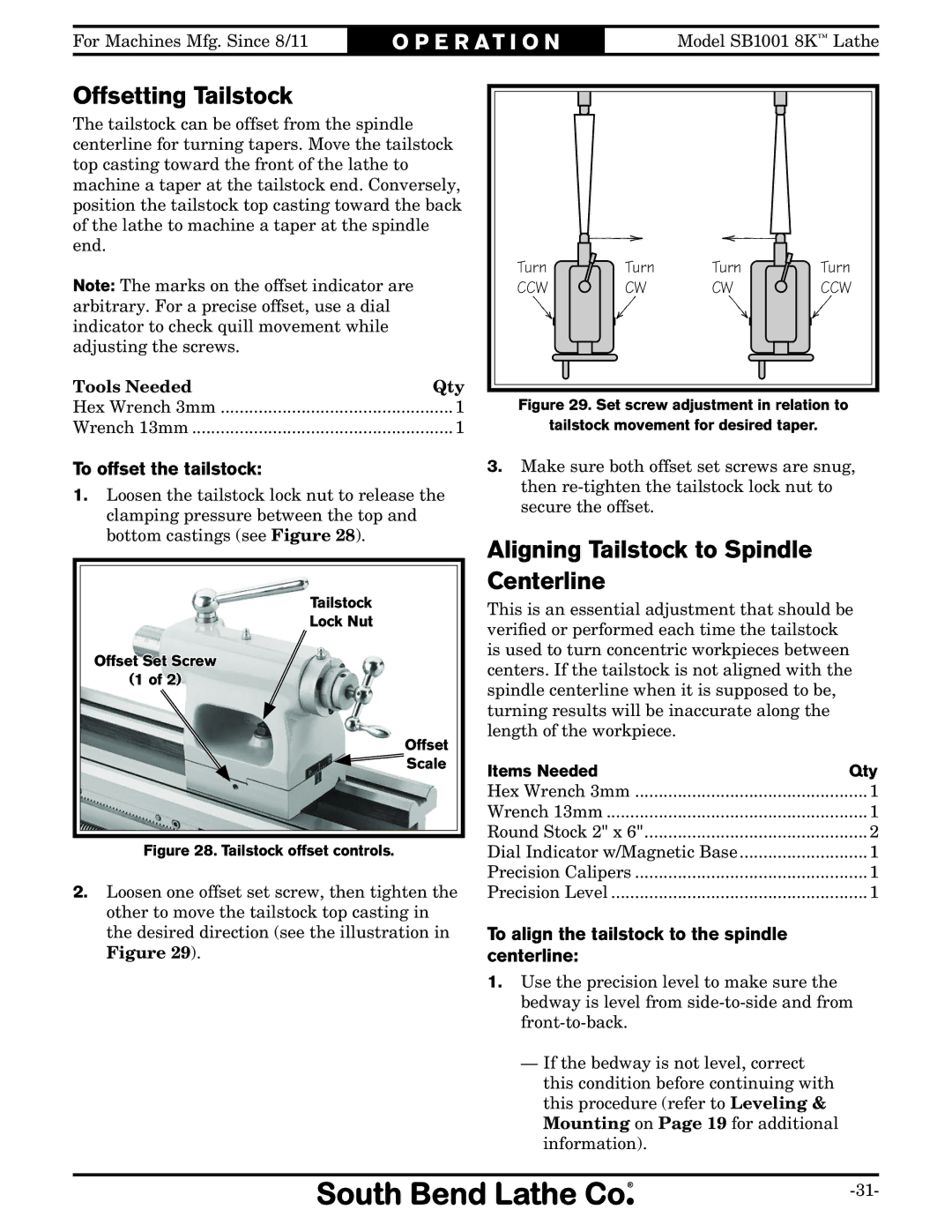

2.Loosen one offset set screw, then tighten the other to move the tailstock top casting in the desired direction (see the illustration in Figure 29).

Turn | Turn | Turn | Turn |

CCW | CW | CW | CCW |

Figure 29. Set screw adjustment in relation to

tailstock movement for desired taper.

3.Make sure both offset set screws are snug, then

Aligning Tailstock to Spindle Centerline

This is an essential adjustment that should be verified or performed each time the tailstock is used to turn concentric workpieces between centers. If the tailstock is not aligned with the spindle centerline when it is supposed to be, turning results will be inaccurate along the length of the workpiece.

Items Needed | Qty |

Hex Wrench 3mm | 1 |

Wrench 13mm | 1 |

Round Stock 2" x 6" | 2 |

Dial Indicator w/Magnetic Base | 1 |

Precision Calipers | 1 |

Precision Level | 1 |

To align the tailstock to the spindle centerline:

1.Use the precision level to make sure the bedway is level from

—If the bedway is not level, correct this condition before continuing with this procedure (refer to Leveling & Mounting on Page 19 for additional information).