For Machines Mfg. Since 8/11 | O P E R A T I O N | Model SB1001 8K™ Lathe |

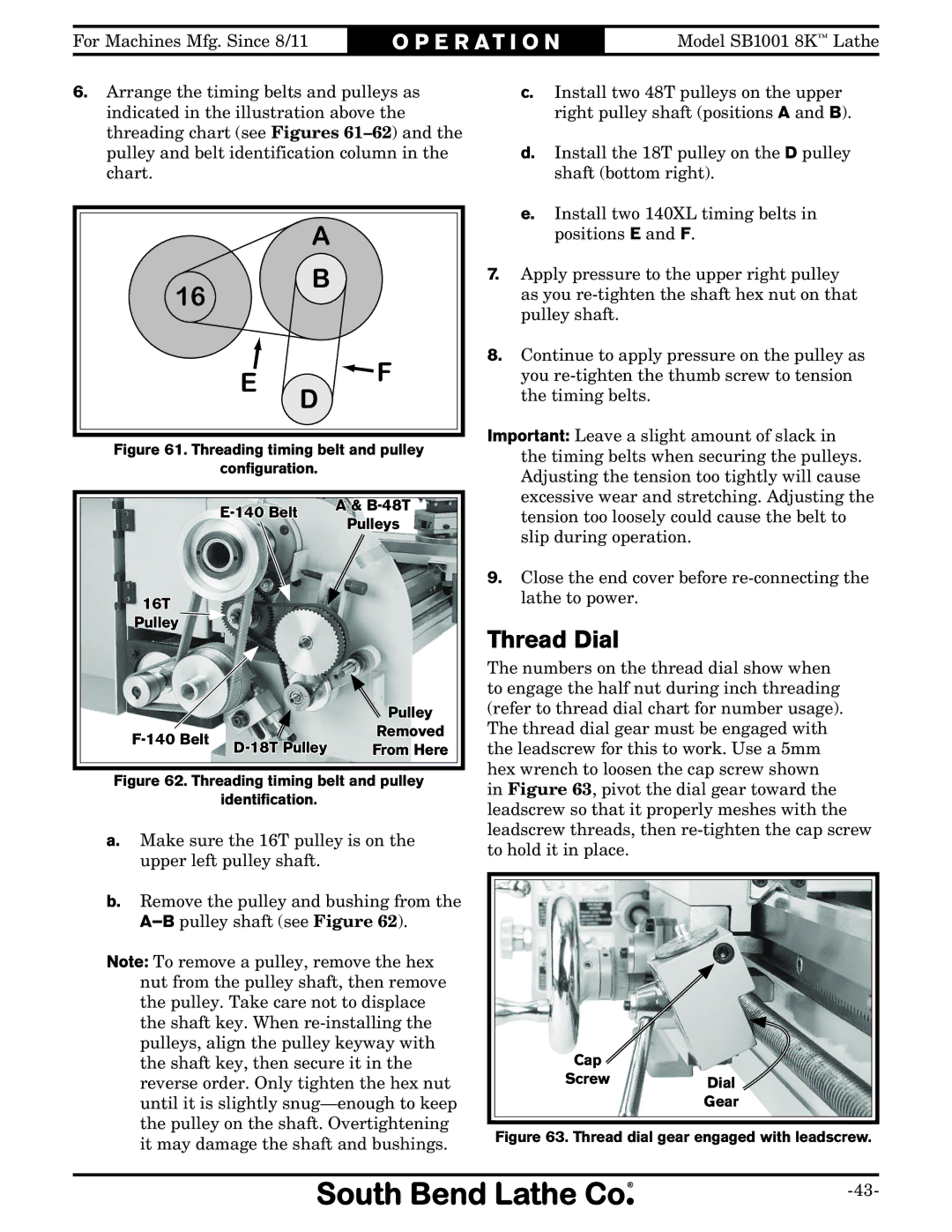

6.Arrange the timing belts and pulleys as indicated in the illustration above the threading chart (see Figures

A

16 B

E![]()

![]() F

F

D

Figure 61. Threading timing belt and pulley

configuration.

|

| A & | |

| Pulleys | ||

|

| ||

16T |

|

| |

Pulley |

|

| |

|

| Pulley | |

Removed | |||

From Here | |||

|

Figure 62. Threading timing belt and pulley

identification.

a.Make sure the 16T pulley is on the upper left pulley shaft.

c.Install two 48T pulleys on the upper right pulley shaft (positions A and B).

d.Install the 18T pulley on the D pulley shaft (bottom right).

e.Install two 140XL timing belts in positions E and F.

7.Apply pressure to the upper right pulley as you

8.Continue to apply pressure on the pulley as you

Important: Leave a slight amount of slack in the timing belts when securing the pulleys. Adjusting the tension too tightly will cause excessive wear and stretching. Adjusting the tension too loosely could cause the belt to slip during operation.

9.Close the end cover before

Thread Dial

The numbers on the thread dial show when to engage the half nut during inch threading (refer to thread dial chart for number usage). The thread dial gear must be engaged with the leadscrew for this to work. Use a 5mm hex wrench to loosen the cap screw shown in Figure 63, pivot the dial gear toward the leadscrew so that it properly meshes with the leadscrew threads, then

b.Remove the pulley and bushing from the

Note: To remove a pulley, remove the hex nut from the pulley shaft, then remove the pulley. Take care not to displace the shaft key. When

Cap

ScrewDial

Gear