For Machines Mfg. Since 8/09 | O P E R A T I O N | Model SB1017 |

Blade Tension

Proper tension is essential to avoid vibration, twist, or`slippage on the wheels. A correctly tensioned blade provides long life, straight cuts, and efficient cutting times.

The three major signs of incorrect tension are:

1)The blade stalls in the cut and slips on the wheels, 2) the blade frequently breaks, and 3) the cuts are not straight.

To tension the blade on the bandsaw:

1.Make sure the blade is tracking properly (refer to Blade Tracking on Page 35).

2.DISCONNECT BANDSAW FROM POWER!

3.Loosen and slide the blade guide as far out as it will go, then tighten it down again.

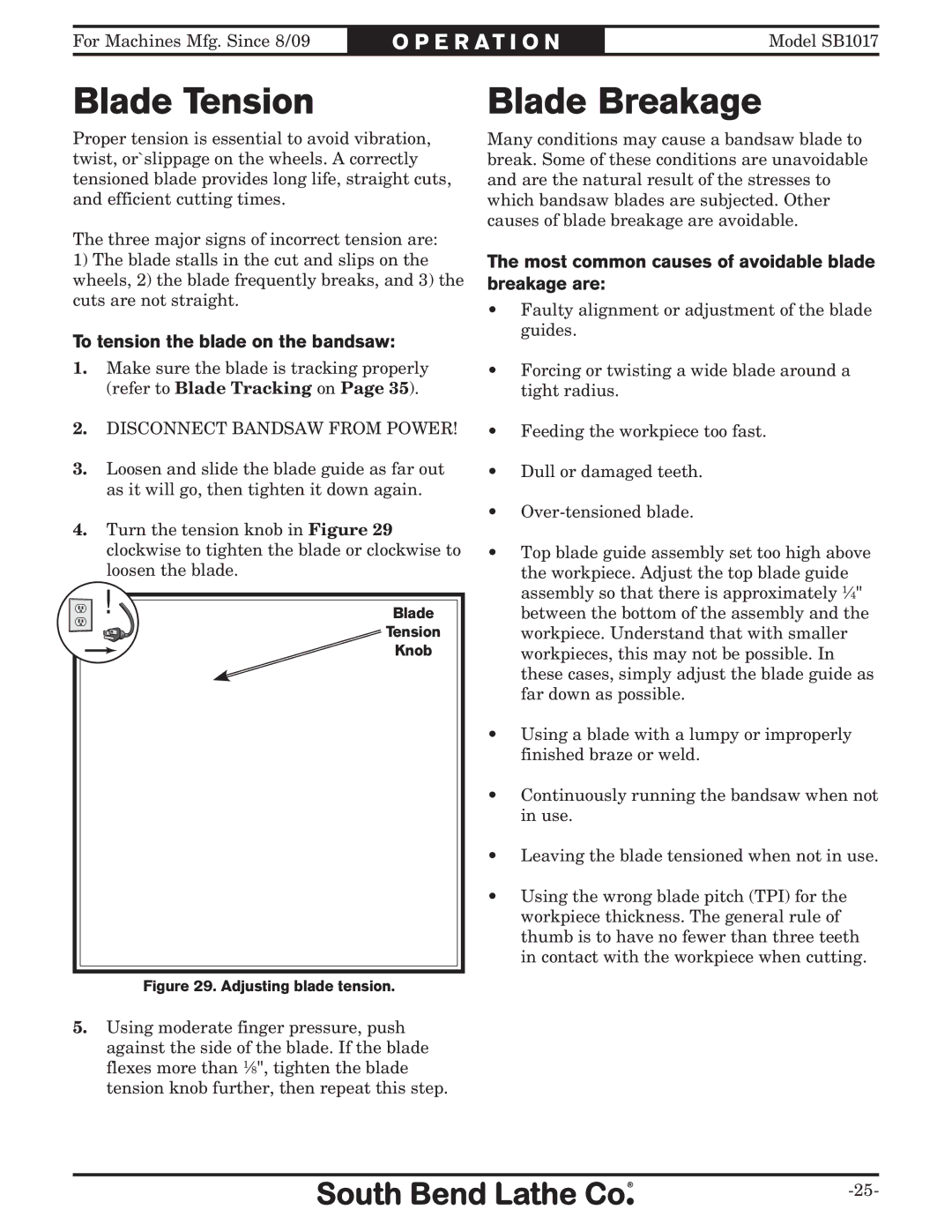

4.Turn the tension knob in Figure 29 clockwise to tighten the blade or clockwise to loosen the blade.

! | Blade |

| Tension |

| Knob |

Figure 29. Adjusting blade tension.

5.Using moderate finger pressure, push against the side of the blade. If the blade flexes more than 1⁄8", tighten the blade tension knob further, then repeat this step.

blade selection

Blade Breakage

Many conditions may cause a bandsaw blade to break. Some of these conditions are unavoidable and are the natural result of the stresses to which bandsaw blades are subjected. Other causes of blade breakage are avoidable.

The most common causes of avoidable blade breakage are:

•Faulty alignment or adjustment of the blade guides.

•Forcing or twisting a wide blade around a tight radius.

•Feeding the workpiece too fast.

•Dull or damaged teeth.

•

•Top blade guide assembly set too high above the workpiece. Adjust the top blade guide assembly so that there is approximately 1⁄4" between the bottom of the assembly and the workpiece. Understand that with smaller workpieces, this may not be possible. In these cases, simply adjust the blade guide as far down as possible.

•Using a blade with a lumpy or improperly finished braze or weld.

•Continuously running the bandsaw when not in use.

•Leaving the blade tensioned when not in use.

•Using the wrong blade pitch (TPI) for the workpiece thickness. The general rule of thumb is to have no fewer than three teeth in contact with the workpiece when cutting.