Model SB1017 | O P E R A T I O N | For Machines Mfg. Since 8/09 |

Downfeed Pressure

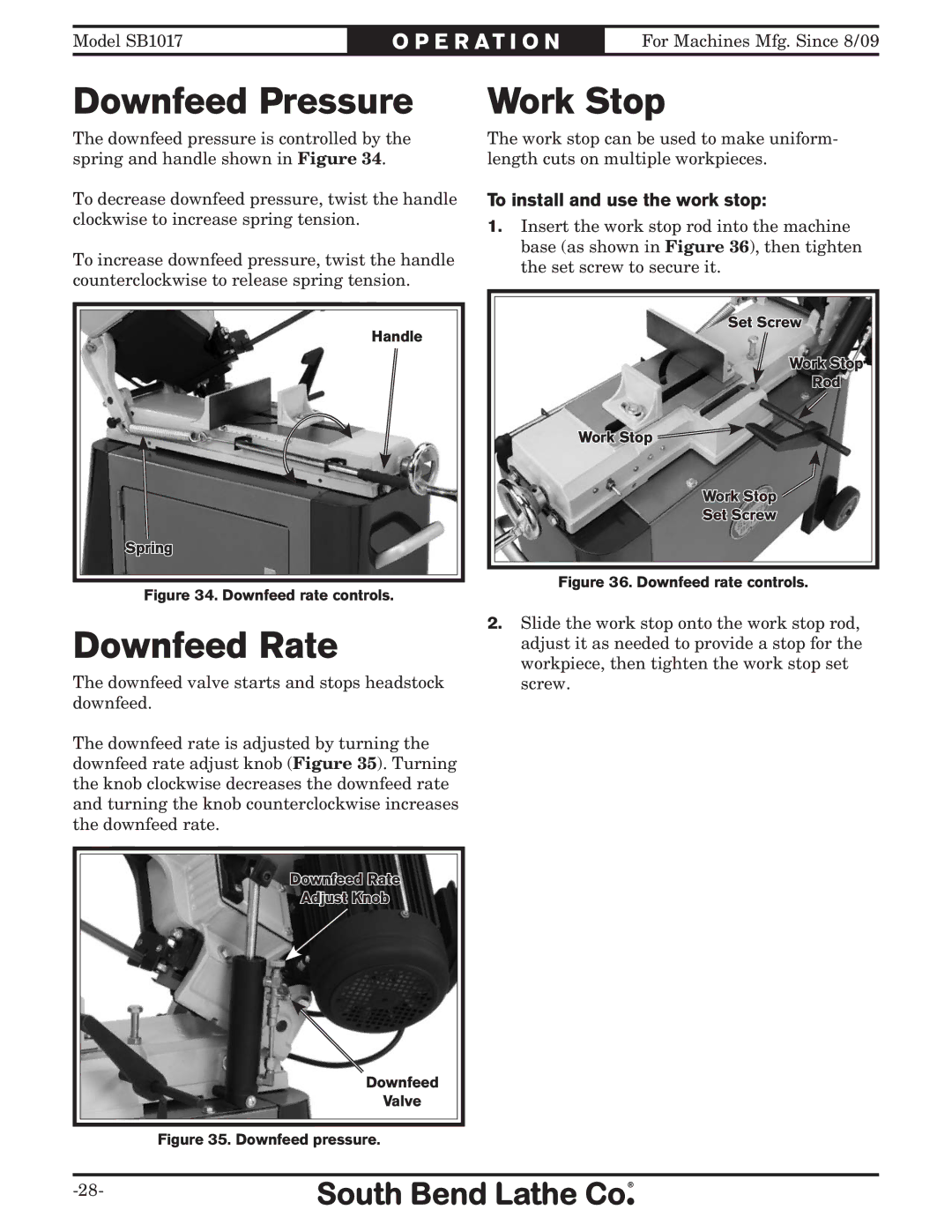

The downfeed pressure is controlled by the spring and handle shown in Figure 34.

To decrease downfeed pressure, twist the handle clockwise to increase spring tension.

To increase downfeed pressure, twist the handle counterclockwise to release spring tension.

Handle

Spring

Figure 34. Downfeed rate controls.

Downfeed Rate

The downfeed valve starts and stops headstock downfeed.

The downfeed rate is adjusted by turning the downfeed rate adjust knob (Figure 35). Turning the knob clockwise decreases the downfeed rate and turning the knob counterclockwise increases the downfeed rate.

Downfeed Rate

Adjust Knob

Downfeed

Valve

Figure 35. Downfeed pressure.

Work Stop

The work stop can be used to make uniform- length cuts on multiple workpieces.

To install and use the work stop:

1.Insert the work stop rod into the machine base (as shown in Figure 36), then tighten the set screw to secure it.

Set Screw

Work Stop

Rod

Work Stop ![]()

Work Stop ![]()

Set Screw

Figure 36. Downfeed rate controls.

2.Slide the work stop onto the work stop rod, adjust it as needed to provide a stop for the workpiece, then tighten the work stop set screw.