For Machines Mfg. Since 8/09 | M A I N T E N A N C E | Model SB1017 |

MaintenanceAINTENANCESchedule

For optimum performance from your machine, follow this maintenance schedule and refer to any specific instructions given in this section.

Lubrication

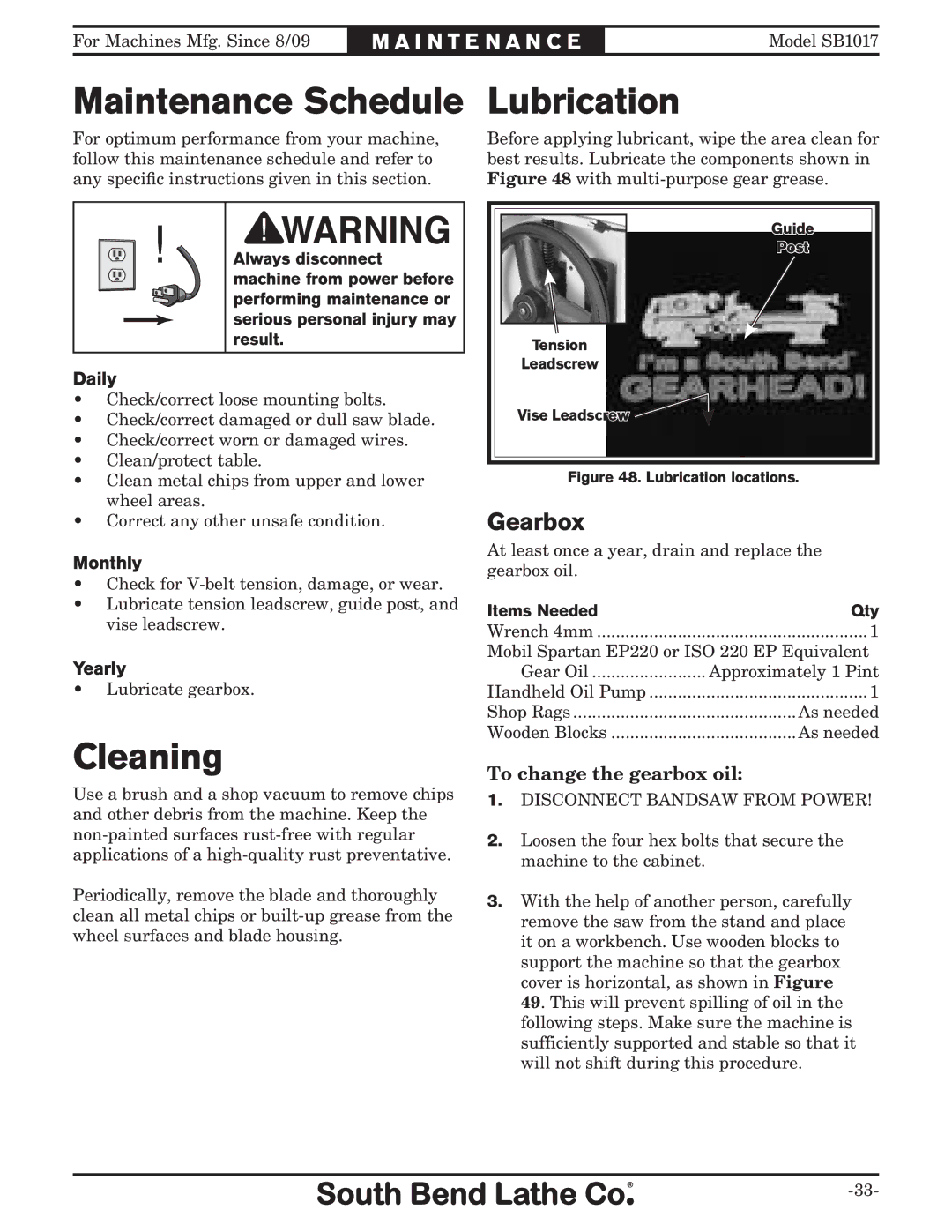

Before applying lubricant, wipe the area clean for best results. Lubricate the components shown in Figure 48 with

! | Always disconnect |

| machine from power before |

| performing maintenance or |

| serious personal injury may |

| result. |

Daily

•Check/correct loose mounting bolts.

•Check/correct damaged or dull saw blade.

•Check/correct worn or damaged wires.

•Clean/protect table.

•Clean metal chips from upper and lower wheel areas.

•Correct any other unsafe condition.

Monthly

•Check for

•Lubricate tension leadscrew, guide post, and vise leadscrew.

Yearly

•Lubricate gearbox.

Cleaning

Use a brush and a shop vacuum to remove chips and other debris from the machine. Keep the

Periodically, remove the blade and thoroughly clean all metal chips or

Guide

Post

Tension

Leadscrew

Vise Leadscrew![]()

![]()

Figure 48. Lubrication locations.

Gearbox

At least once a year, drain and replace the gearbox oil.

Items Needed | Qty |

Wrench 4mm | 1 |

Mobil Spartan EP220 or ISO 220 EP Equivalent | |

Gear Oil | Approximately 1 Pint |

Handheld Oil Pump | 1 |

Shop Rags | As needed |

Wooden Blocks | As needed |

To change the gearbox oil:

1.DISCONNECT BANDSAW FROM POWER!

2.Loosen the four hex bolts that secure the machine to the cabinet.

3.With the help of another person, carefully remove the saw from the stand and place it on a workbench. Use wooden blocks to support the machine so that the gearbox cover is horizontal, as shown in Figure

49. This will prevent spilling of oil in the following steps. Make sure the machine is sufficiently supported and stable so that it will not shift during this procedure.