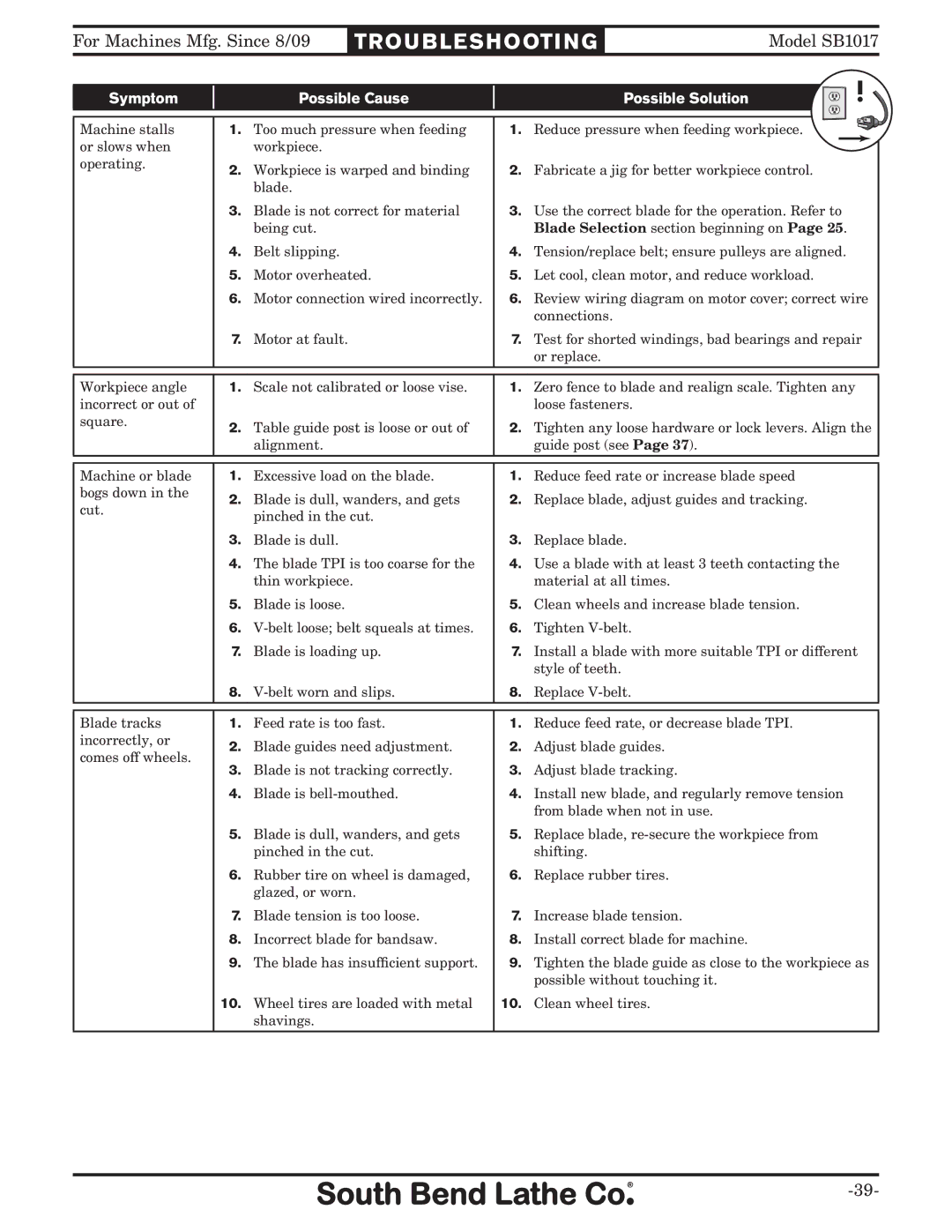

For Machines Mfg. Since 8/09 | TROUBLESHOOTING | Model SB1017 |

Symptom

Possible Cause

Possible Solution | ! |

Machine stalls | 1. | Too much pressure when feeding | 1. | Reduce pressure when feeding workpiece. |

or slows when |

| workpiece. |

|

|

operating. | 2. | Workpiece is warped and binding | 2. | Fabricate a jig for better workpiece control. |

| ||||

|

| blade. |

|

|

3.Blade is not correct for material 3. Use the correct blade for the operation. Refer to

|

| being cut. |

| Blade Selection section beginning on Page 25. | |

| 4. | Belt slipping. | 4. | Tension/replace belt; ensure pulleys are aligned. | |

| 5. | Motor overheated. | 5. | Let cool, clean motor, and reduce workload. | |

| 6. | Motor connection wired incorrectly. | 6. | Review wiring diagram on motor cover; correct wire | |

|

|

|

| connections. | |

| 7. | Motor at fault. | 7. | Test for shorted windings, bad bearings and repair | |

|

|

|

| or replace. | |

|

|

|

|

| |

|

|

|

|

| |

Workpiece angle | 1. | Scale not calibrated or loose vise. | 1. | Zero fence to blade and realign scale. Tighten any | |

incorrect or out of |

|

|

| loose fasteners. | |

square. | 2. | Table guide post is loose or out of | 2. | Tighten any loose hardware or lock levers. Align the | |

| |||||

|

| alignment. |

| guide post (see Page 37). | |

|

|

|

|

| |

|

|

|

|

| |

Machine or blade | 1. | Excessive load on the blade. | 1. | Reduce feed rate or increase blade speed | |

bogs down in the | 2. | Blade is dull, wanders, and gets | 2. | Replace blade, adjust guides and tracking. | |

cut. | |||||

| pinched in the cut. |

|

| ||

|

|

|

| ||

| 3. | Blade is dull. | 3. | Replace blade. | |

| 4. | The blade TPI is too coarse for the | 4. | Use a blade with at least 3 teeth contacting the | |

|

| thin workpiece. |

| material at all times. | |

| 5. | Blade is loose. | 5. | Clean wheels and increase blade tension. | |

| 6. | 6. | Tighten | ||

| 7. | Blade is loading up. | 7. | Install a blade with more suitable TPI or different | |

|

|

|

| style of teeth. | |

| 8. | 8. | Replace | ||

|

|

|

|

| |

|

|

|

|

| |

Blade tracks | 1. | Feed rate is too fast. | 1. | Reduce feed rate, or decrease blade TPI. | |

incorrectly, or | 2. | Blade guides need adjustment. | 2. | Adjust blade guides. | |

comes off wheels. | |||||

3. | Blade is not tracking correctly. | 3. | Adjust blade tracking. | ||

| |||||

| 4. | Blade is | 4. | Install new blade, and regularly remove tension | |

|

|

|

| from blade when not in use. |

5.Blade is dull, wanders, and gets 5. Replace blade,

| pinched in the cut. |

| shifting. |

6. | Rubber tire on wheel is damaged, | 6. | Replace rubber tires. |

| glazed, or worn. |

|

|

7. | Blade tension is too loose. | 7. | Increase blade tension. |

8. | Incorrect blade for bandsaw. | 8. | Install correct blade for machine. |

9. | The blade has insufficient support. | 9. | Tighten the blade guide as close to the workpiece as |

|

|

| possible without touching it. |

10. | Wheel tires are loaded with metal | 10. | Clean wheel tires. |

| shavings. |

|

|