Model SB1017TROUBLESHOOTING For Machines Mfg. Since 8/09

TROUBLESHOOTING

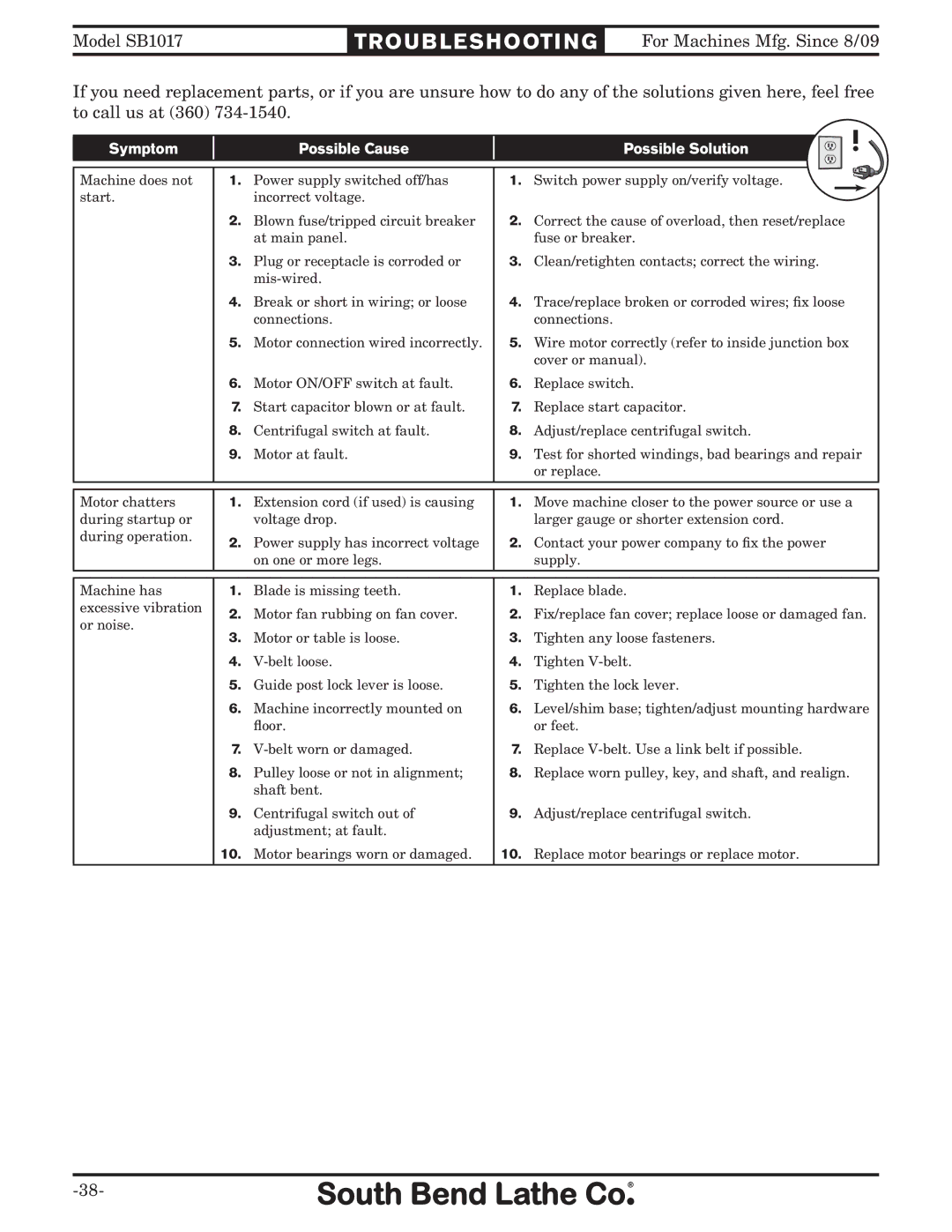

If you need replacement parts, or if you are unsure how to do any of the solutions given here, feel free to call us at (360)

Symptom | Possible Cause | Possible Solution | ! |

Machine does not | 1. Power supply switched off/has | 1. Switch power supply on/verify voltage. |

|

start. | incorrect voltage. |

|

|

2.Blown fuse/tripped circuit breaker 2. Correct the cause of overload, then reset/replace

at main panel. | fuse or breaker. |

3.Plug or receptacle is corroded or 3. Clean/retighten contacts; correct the wiring.

4.Break or short in wiring; or loose 4. Trace/replace broken or corroded wires; fix loose

connections. | connections. |

5.Motor connection wired incorrectly. 5. Wire motor correctly (refer to inside junction box cover or manual).

| 6. | Motor ON/OFF switch at fault. | 6. | Replace switch. | |

| 7. | Start capacitor blown or at fault. | 7. | Replace start capacitor. | |

| 8. | Centrifugal switch at fault. | 8. | Adjust/replace centrifugal switch. | |

| 9. | Motor at fault. | 9. | Test for shorted windings, bad bearings and repair | |

|

|

|

| or replace. | |

|

|

|

|

| |

|

|

|

|

| |

Motor chatters | 1. | Extension cord (if used) is causing | 1. | Move machine closer to the power source or use a | |

during startup or |

| voltage drop. |

| larger gauge or shorter extension cord. | |

during operation. | 2. | Power supply has incorrect voltage | 2. | Contact your power company to fix the power | |

| |||||

|

| on one or more legs. |

| supply. | |

|

|

|

|

| |

|

|

|

|

| |

Machine has | 1. | Blade is missing teeth. | 1. | Replace blade. | |

excessive vibration | 2. | Motor fan rubbing on fan cover. | 2. | Fix/replace fan cover; replace loose or damaged fan. | |

or noise. | |||||

3. | Motor or table is loose. | 3. | Tighten any loose fasteners. | ||

| |||||

| 4. | 4. | Tighten | ||

| 5. | Guide post lock lever is loose. | 5. | Tighten the lock lever. |

6.Machine incorrectly mounted on 6. Level/shim base; tighten/adjust mounting hardware

floor. | or feet. |

7.

8.Pulley loose or not in alignment; 8. Replace worn pulley, key, and shaft, and realign. shaft bent.

9. Centrifugal switch out of | 9. Adjust/replace centrifugal switch. |

adjustment; at fault. |

|

10.Motor bearings worn or damaged. 10. Replace motor bearings or replace motor.