For Machines Mfg. Since 8/09 | O P E R A T I O N | Model SB1019 |

Blade Pitch (TPI)

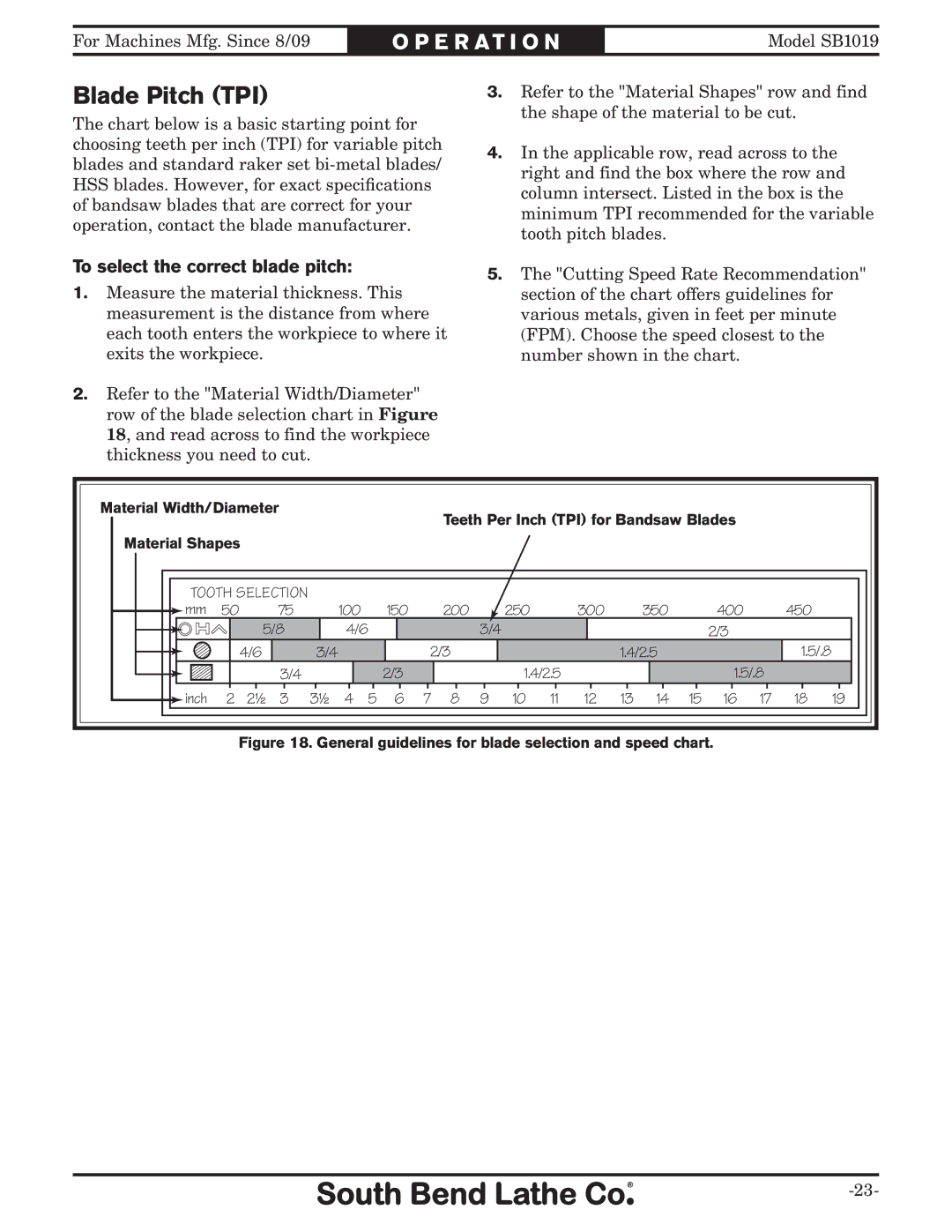

The chart below is a basic starting point for choosing teeth per inch (TPI) for variable pitch blades and standard raker set

To select the correct blade pitch:

1.Measure the material thickness. This measurement is the distance from where each tooth enters the workpiece to where it exits the workpiece.

2.Refer to the "Material Width/Diameter" row of the blade selection chart in Figure 18, and read across to find the workpiece thickness you need to cut.

3.Refer to the "Material Shapes" row and find the shape of the material to be cut.

4.In the applicable row, read across to the right and find the box where the row and column intersect. Listed in the box is the minimum TPI recommended for the variable tooth pitch blades.

5.The "Cutting Speed Rate Recommendation" section of the chart offers guidelines for various metals, given in feet per minute (FPM). Choose the speed closest to the number shown in the chart.

Material Width/Diameter |

|

|

|

|

| Teeth Per Inch (TPI) for Bandsaw Blades |

|

|

| |||||||||||

|

|

|

|

|

|

|

|

|

|

|

| |||||||||

Material Shapes |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

TOOTH SELECTION |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

mm | 50 |

| 75 |

| 100 |

| 150 |

| 200 |

| 250 |

| 300 |

| 350 |

| 400 |

| 450 |

|

|

| 5/8 |

| 4/6 |

|

|

| 3/4 |

|

|

|

|

|

| 2/3 |

|

|

| ||

|

| 4/6 |

| 3/4 |

|

|

| 2/3 |

|

|

|

| 1.4/2.5 |

|

|

| 1.5/.8 |

| ||

|

|

| 3/4 |

|

|

| 2/3 |

|

|

| 1.4/2.5 |

|

|

|

| 1.5/.8 |

|

| ||

inch | 2 | 2½ | 3 | 3½ | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 |