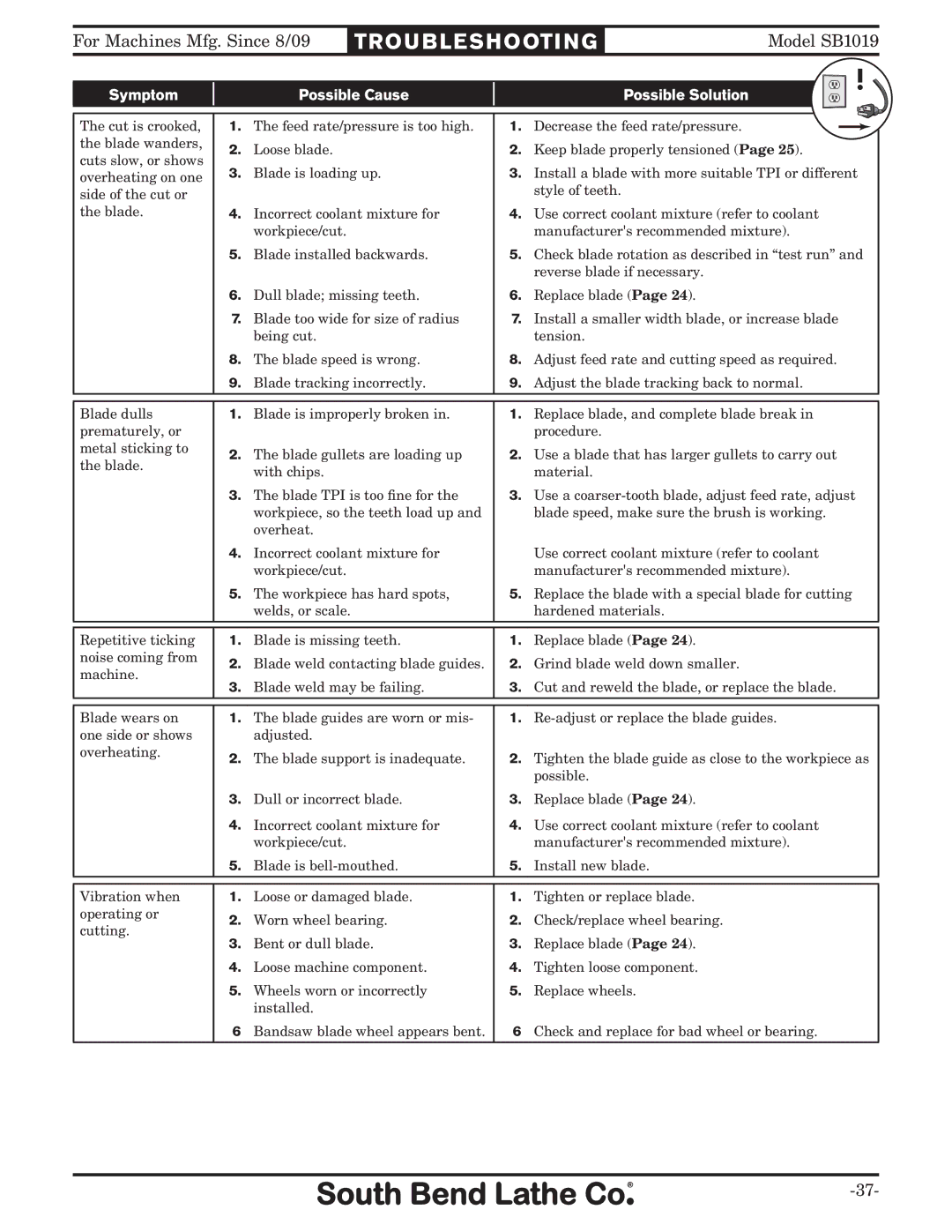

For Machines Mfg. Since 8/09 | TROUBLESHOOTI NG | Model SB1019 |

Symptom

Possible Cause

Possible Solution | ! |

|

The cut is crooked, | 1. | The feed rate/pressure is too high. | 1. | Decrease the feed rate/pressure. |

| |

| ||||||

the blade wanders, | 2. | Loose blade. | 2. | Keep blade properly tensioned (Page 25). | ||

cuts slow, or shows | ||||||

3. | Blade is loading up. | 3. | Install a blade with more suitable TPI or different | |||

overheating on one | ||||||

side of the cut or |

|

|

| style of teeth. | ||

the blade. | 4. | Incorrect coolant mixture for | 4. | Use correct coolant mixture (refer to coolant | ||

|

| workpiece/cut. |

| manufacturer's recommended mixture). | ||

5.Blade installed backwards.5. Check blade rotation as described in “test run” and reverse blade if necessary.

6. Dull blade; missing teeth. | 6. Replace blade (Page 24). |

7.Blade too wide for size of radius 7. Install a smaller width blade, or increase blade

being cut. | tension. |

8.The blade speed is wrong.8. Adjust feed rate and cutting speed as required.

9.Blade tracking incorrectly.9. Adjust the blade tracking back to normal.

Blade dulls | 1. | Blade is improperly broken in. | 1. | Replace blade, and complete blade break in | |

prematurely, or |

|

|

| procedure. | |

metal sticking to | 2. | The blade gullets are loading up | 2. | Use a blade that has larger gullets to carry out | |

the blade. | |||||

| with chips. |

| material. | ||

|

|

|

3.The blade TPI is too fine for the 3. Use a

|

| workpiece, so the teeth load up and |

| blade speed, make sure the brush is working. | |

|

| overheat. |

|

| |

| 4. | Incorrect coolant mixture for |

| Use correct coolant mixture (refer to coolant | |

|

| workpiece/cut. |

| manufacturer's recommended mixture). | |

| 5. | The workpiece has hard spots, | 5. | Replace the blade with a special blade for cutting | |

|

| welds, or scale. |

| hardened materials. | |

|

|

|

|

| |

|

|

|

|

| |

Repetitive ticking | 1. | Blade is missing teeth. | 1. | Replace blade (Page 24). | |

noise coming from | 2. | Blade weld contacting blade guides. | 2. | Grind blade weld down smaller. | |

machine. | |||||

3. | Blade weld may be failing. | 3. | Cut and reweld the blade, or replace the blade. | ||

| |||||

|

|

|

|

| |

|

|

|

|

| |

Blade wears on | 1. | The blade guides are worn or mis- | 1. | ||

one side or shows |

| adjusted. |

|

| |

overheating. | 2. | The blade support is inadequate. | 2. | Tighten the blade guide as close to the workpiece as | |

| |||||

|

|

|

| possible. | |

| 3. | Dull or incorrect blade. | 3. | Replace blade (Page 24). | |

| 4. | Incorrect coolant mixture for | 4. | Use correct coolant mixture (refer to coolant | |

|

| workpiece/cut. |

| manufacturer's recommended mixture). | |

| 5. | Blade is | 5. | Install new blade. | |

|

|

|

|

| |

|

|

|

|

| |

Vibration when | 1. | Loose or damaged blade. | 1. | Tighten or replace blade. | |

operating or | 2. | Worn wheel bearing. | 2. | Check/replace wheel bearing. | |

cutting. | |||||

3. | Bent or dull blade. | 3. | Replace blade (Page 24). | ||

| |||||

| 4. | Loose machine component. | 4. | Tighten loose component. | |

| 5. | Wheels worn or incorrectly | 5. | Replace wheels. | |

|

| installed. |

|

| |

| 6 | Bandsaw blade wheel appears bent. | 6 | Check and replace for bad wheel or bearing. | |

|

|

|

|

|