For Machines Mfg. Since 8/09 | O P E R A T I O N | Model SB1019 |

Cutting Fluid

While simple in concept and function, many issues must be taken into account to find and use the correct cutting fluid. Always follow all product warnings and contact the fluid manufacturer for unanswered questions.

Use the information below as a guideline to choose the appropriate cutting fluid. Always refer to the cutting fluid manufacturer for specific application and safety information:

•For cutting low alloy, low carbon, and

•For cutting stainless steels, high carbon, and high alloy metals, brass, copper and mild

•For cutting cast iron, cutting fluid is not recommended.

Remember: Too much flow at the cutting fluid nozzle will make a mess and can make the work area unsafe; and not enough fluid at the cut will heat the blade, causing the blade teeth to load up and break.

Tip: Using a refractometer or hydrometer to replenish water in

BIOLOGICAL & POISON

HAZARD!

Use the correct personal protection equipment when handling cutting fluid. Follow federal, state, and fluid manufacturer requirements for proper disposal.

Cutting Fluid System

This bandsaw has a

To use the cutting fluid system:

1.Thoroughly clean and remove any foreign material that may have fallen inside the reservoir during shipping.

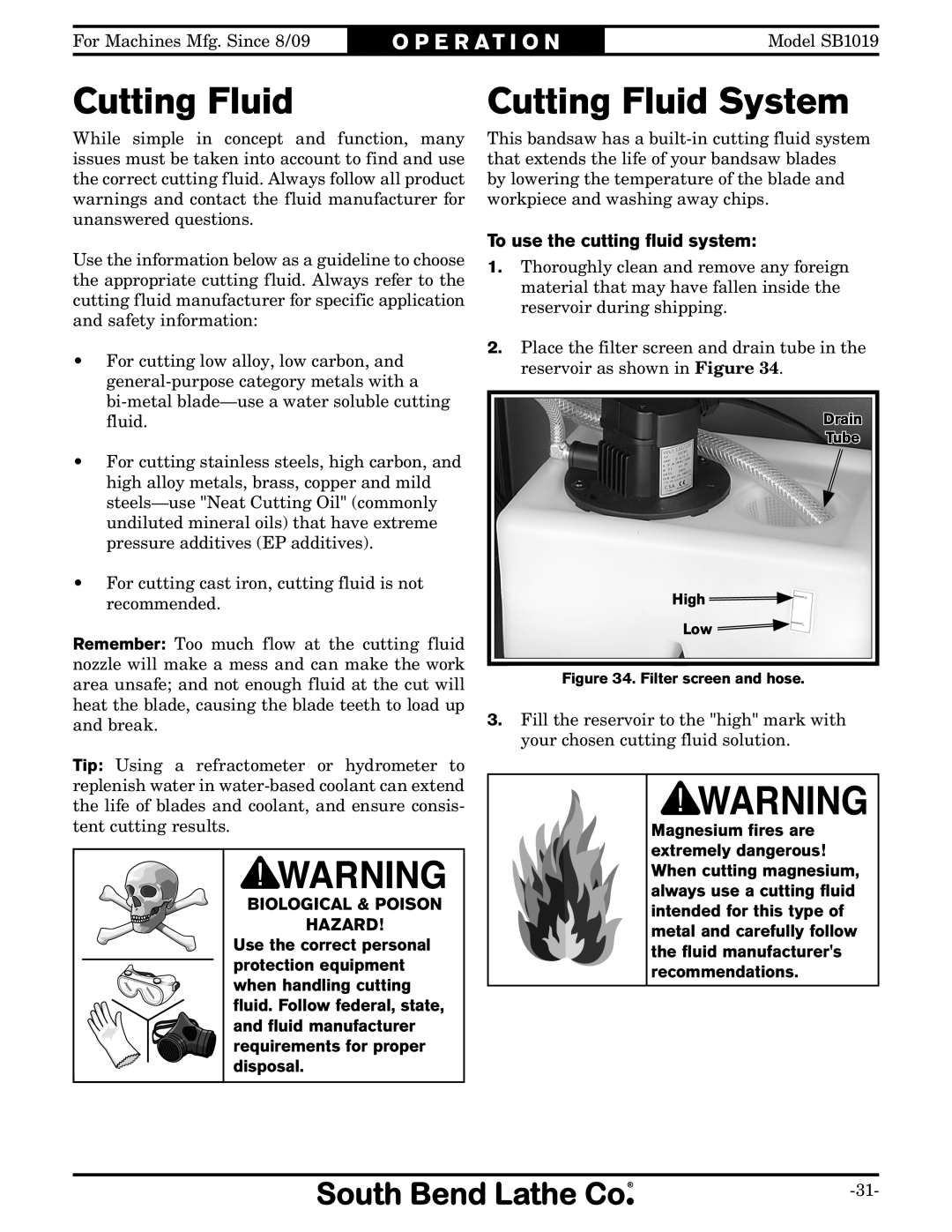

2.Place the filter screen and drain tube in the reservoir as shown in Figure 34.

Drain

Tube

High![]()

![]()

Low![]()

![]()

Figure 34. Filter screen and hose.

3.Fill the reservoir to the "high" mark with your chosen cutting fluid solution.

Magnesium fires are extremely dangerous! When cutting magnesium, always use a cutting fluid intended for this type of metal and carefully follow the fluid manufacturer's recommendations.