For Machines Mfg. Since 8/09 | O P E R A T I O N | Model SB1029 |

7.Wipe the grinding wheel seat shown in Figure 26, so it is perfectly clean, and no paper is left behind.

Note: A slight wiping of the spindle threads, grinding wheel seat, and hub with a lightly- oiled rag is acceptable to prevent rust.

![]()

![]() !

! ![]()

Grinding Wheel

Seat

Figure 26. Wheel mounting hub.

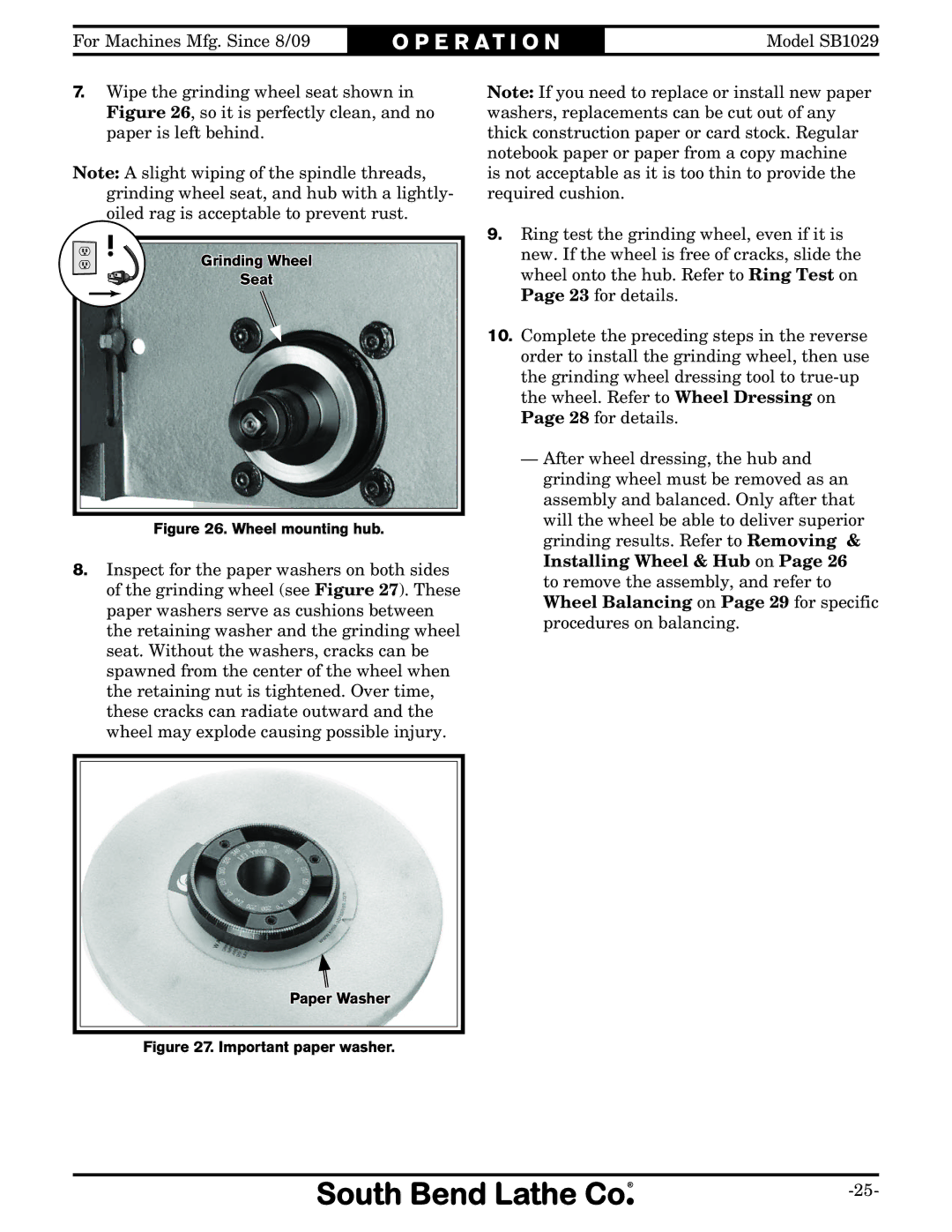

8.Inspect for the paper washers on both sides of the grinding wheel (see Figure 27). These paper washers serve as cushions between the retaining washer and the grinding wheel seat. Without the washers, cracks can be spawned from the center of the wheel when the retaining nut is tightened. Over time, these cracks can radiate outward and the wheel may explode causing possible injury.

Paper Washer

Figure 27. Important paper washer.

Note: If you need to replace or install new paper washers, replacements can be cut out of any thick construction paper or card stock. Regular notebook paper or paper from a copy machine is not acceptable as it is too thin to provide the required cushion.

9.Ring test the grinding wheel, even if it is new. If the wheel is free of cracks, slide the wheel onto the hub. Refer to Ring Test on Page 23 for details.

10.Complete the preceding steps in the reverse order to install the grinding wheel, then use the grinding wheel dressing tool to

—After wheel dressing, the hub and grinding wheel must be removed as an assembly and balanced. Only after that will the wheel be able to deliver superior grinding results. Refer to Removing & Installing Wheel & Hub on Page 26 to remove the assembly, and refer to Wheel Balancing on Page 29 for specific procedures on balancing.